"Tornos" Swiss type CNC sliding head turning machines for complex parts from small to large runs

Numerical control (CNC) automatic turning machines are reserved for bar turning of micro parts with complex shapes that cannot be produced on "Escomatic" bar turning machines. They all contain an additional feeder which automatically loads the material in bars. Unlike the "Escomatic" process, in this case it is the material that turns and the tools are fixed.

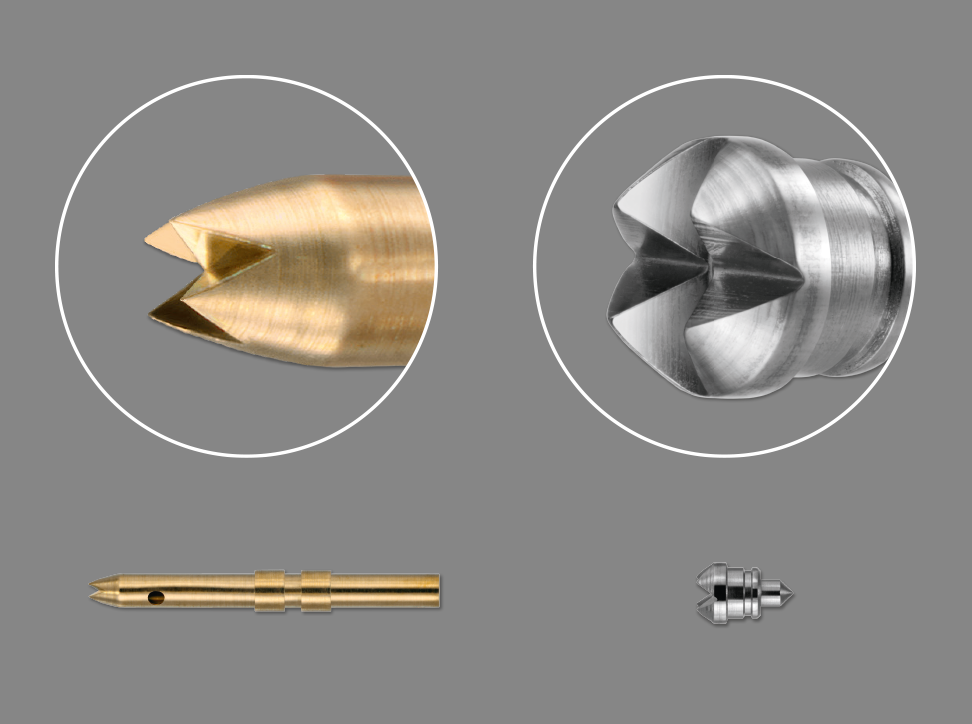

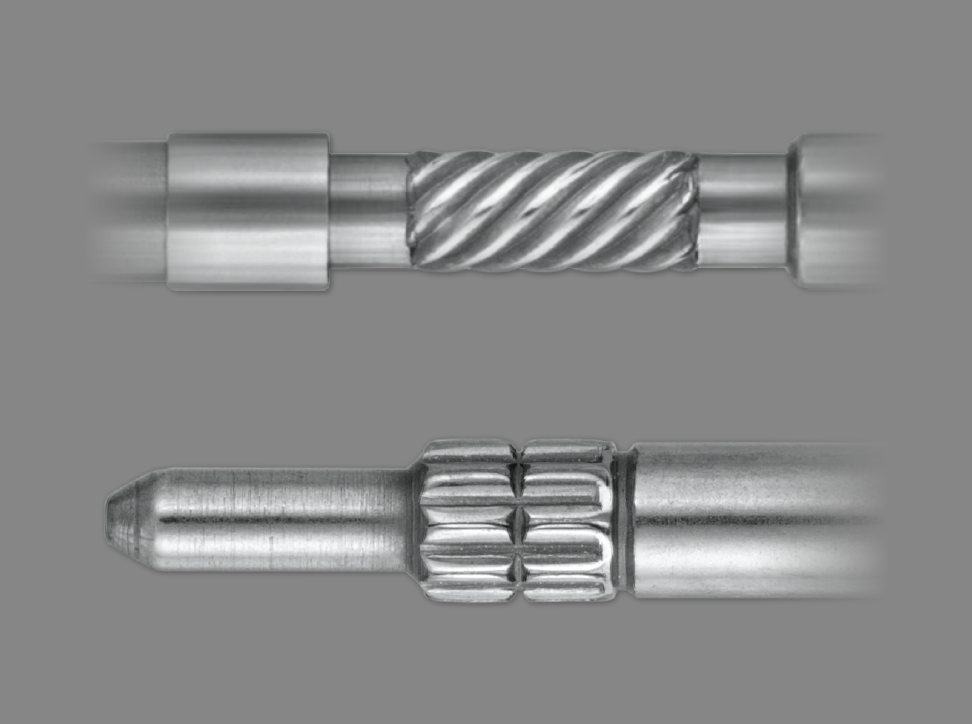

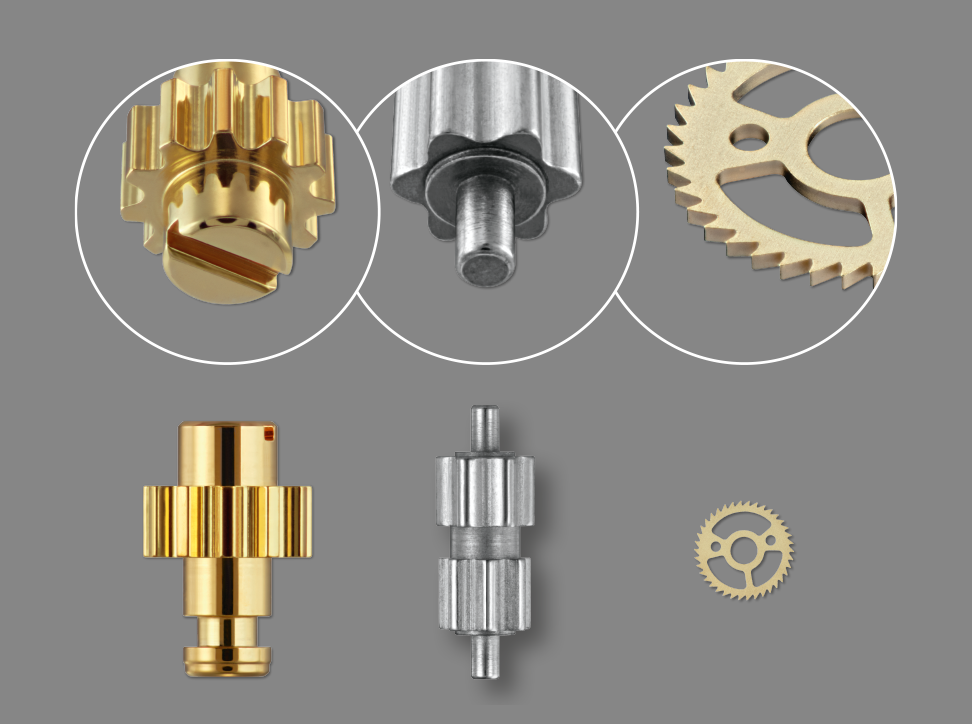

Other technical operations can be performed during the same operating cycle, often as secondary operations: polygon operation, hobbing, milling, drilling,thread-whirling/tapping or threading.

Examples of the most commonly used materials

- mild steels for automatic machines

- hardenable steels for automatic machines

- construction steels

- martensitic stainless steels

- austenitic stainless steels

- copper alloys (CuBe, brass, nickel silver, bronze)

- precious metals (palladium alloy, gold)

- titanium

Usual dimensions

Diameters between 0.05 mm and 6 mm

Max. length 80 mm

Activity sectors

- watchmaking

- automotive

- electronics

- medical

Tolerances

Possibility of achieving tolerances of +/- 2µm (0.002 mm) depending on the material and geometry of the part