Our skills

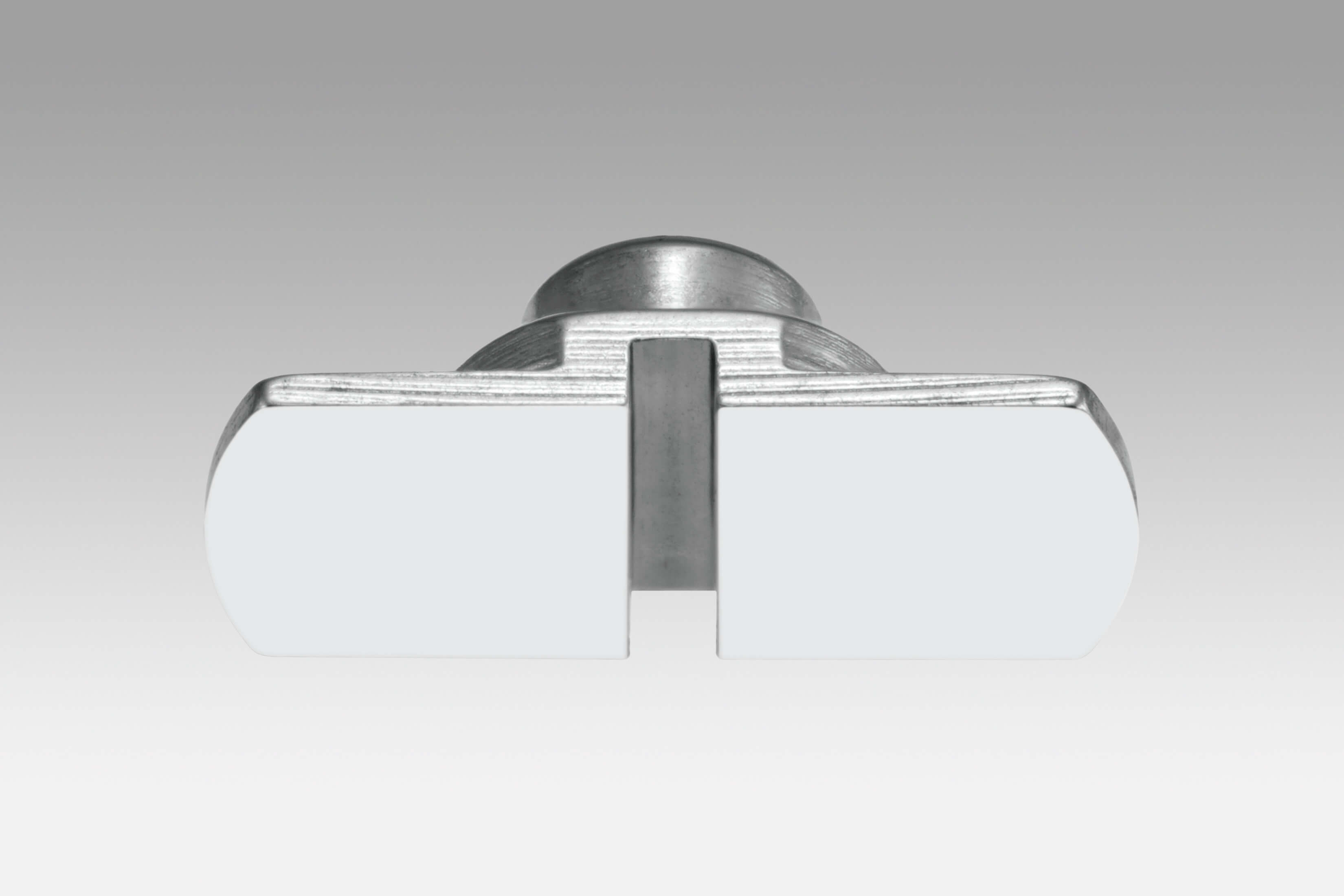

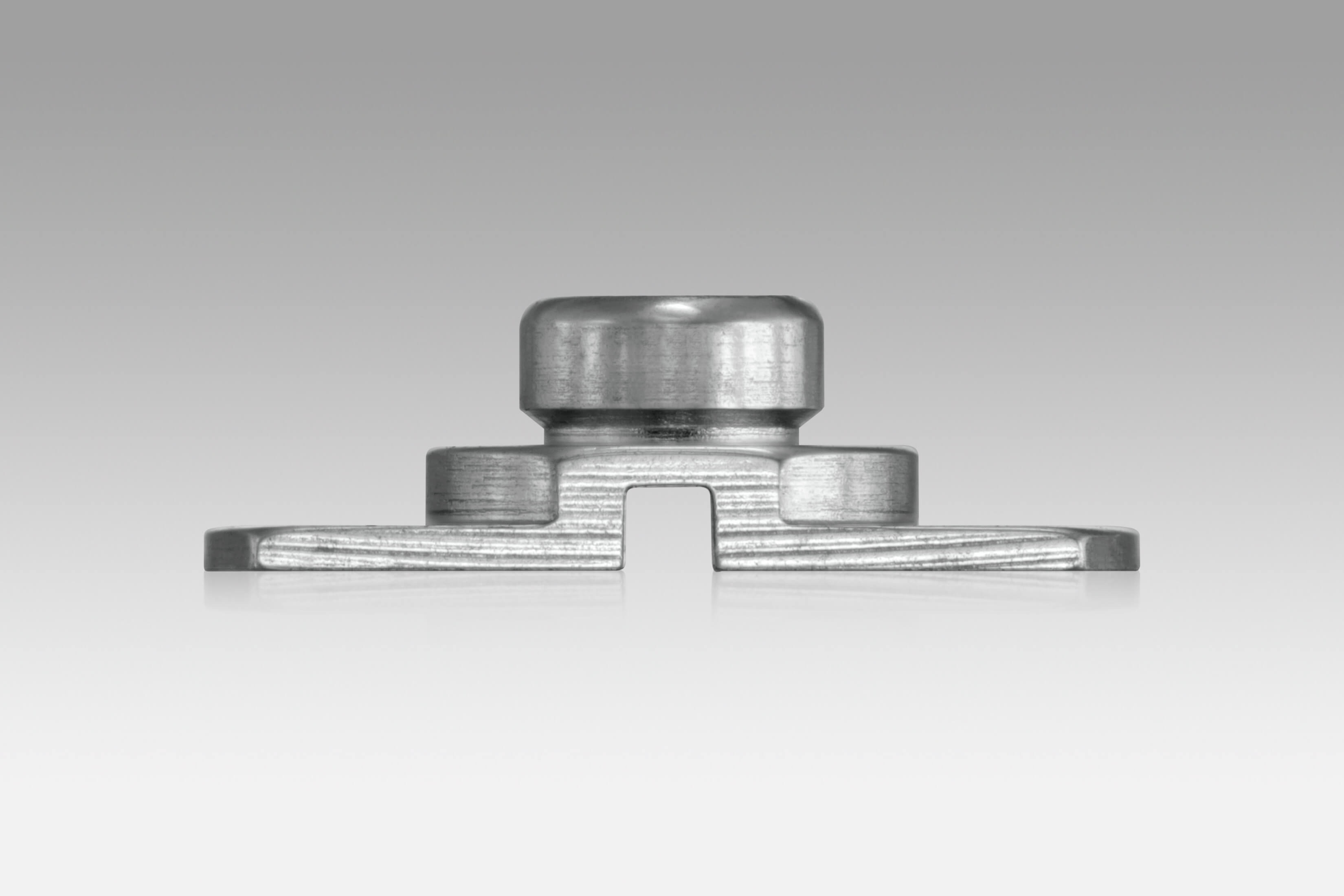

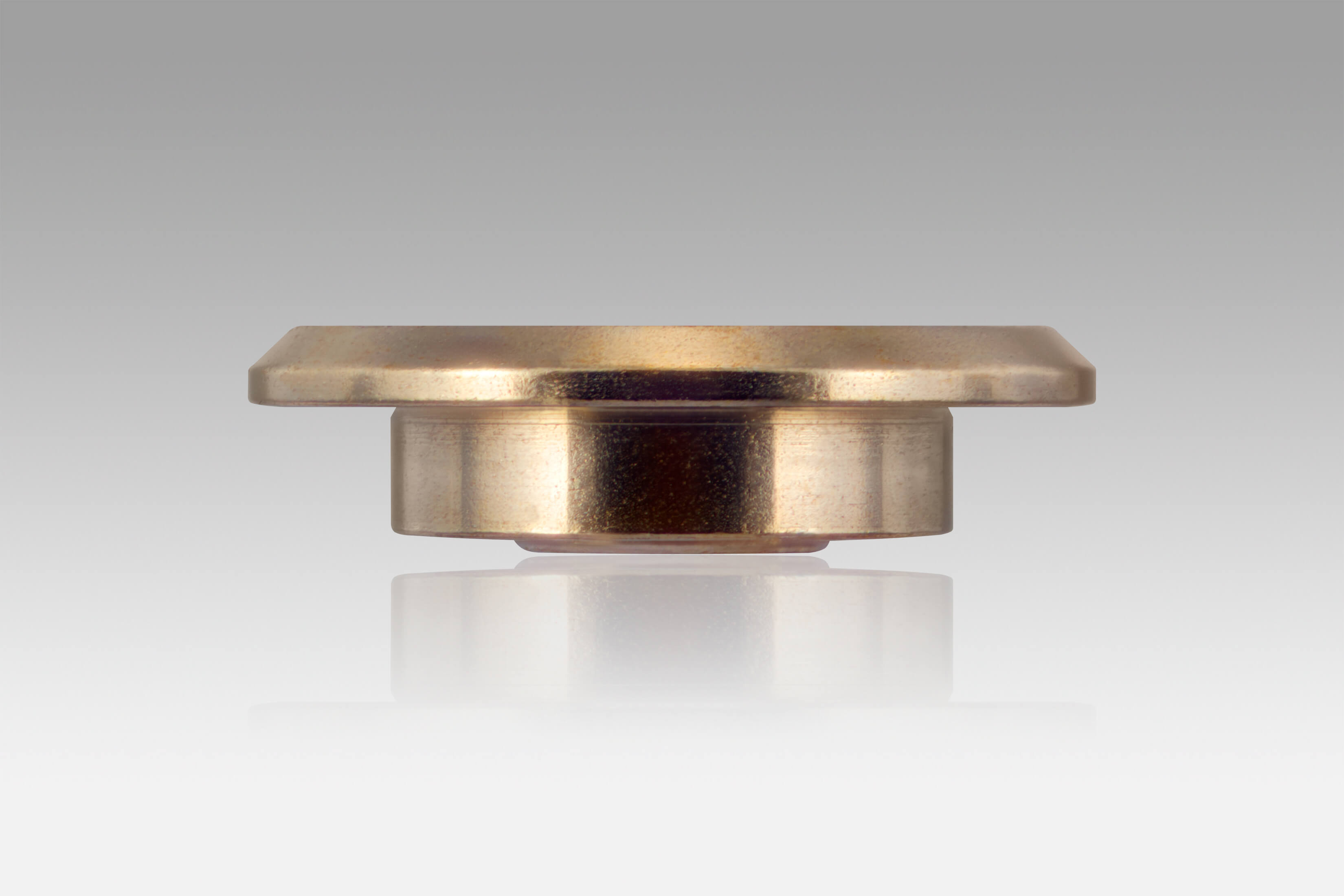

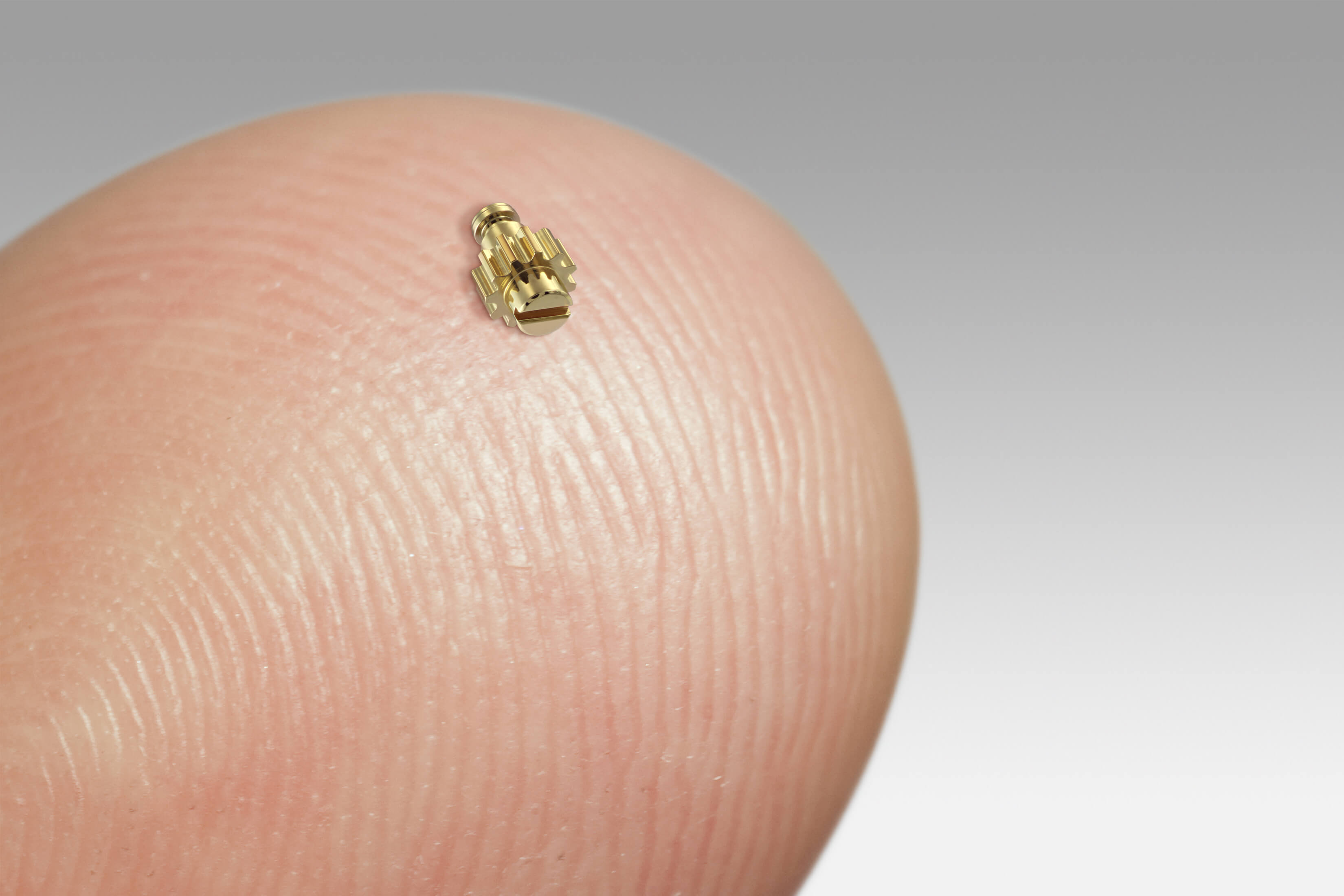

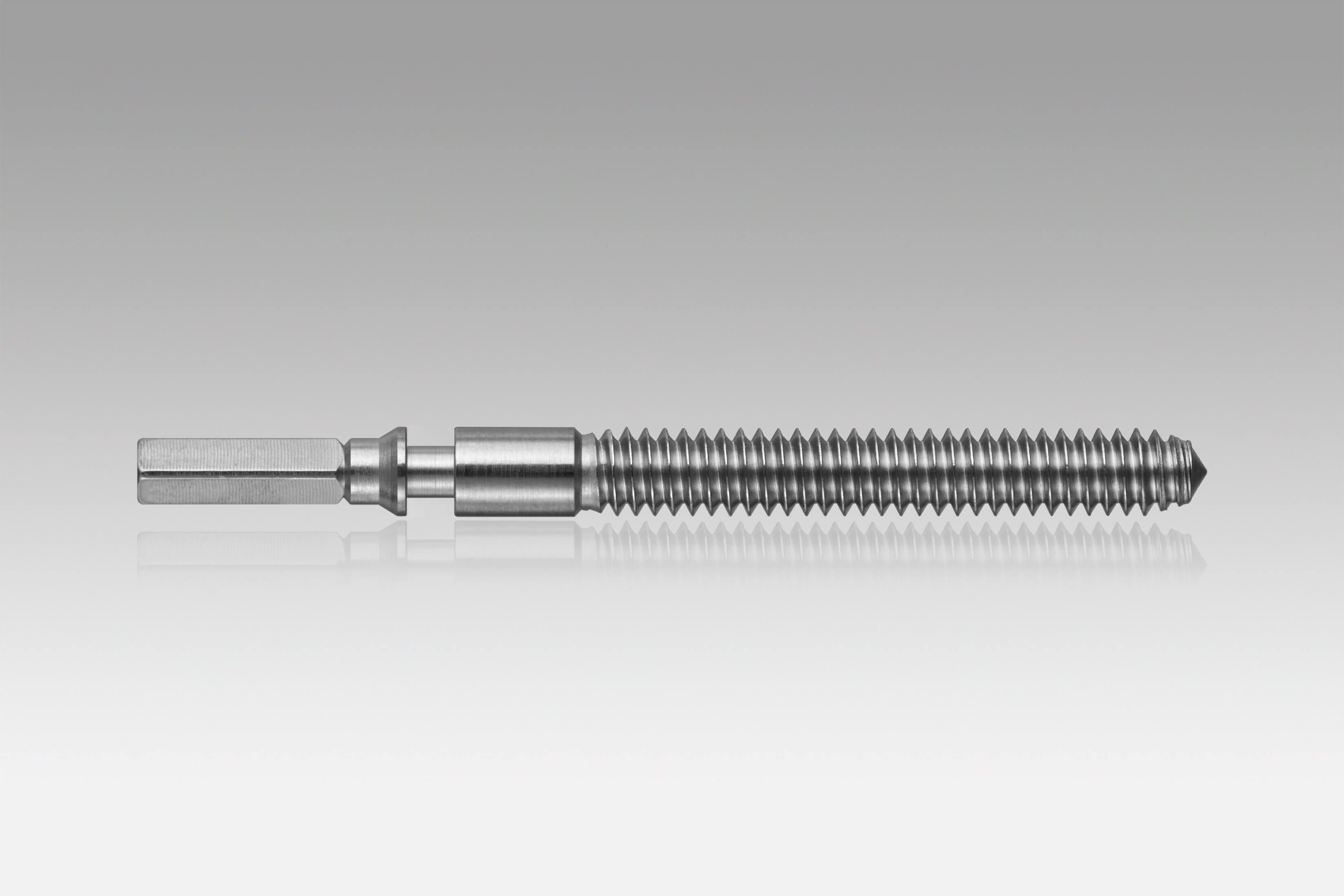

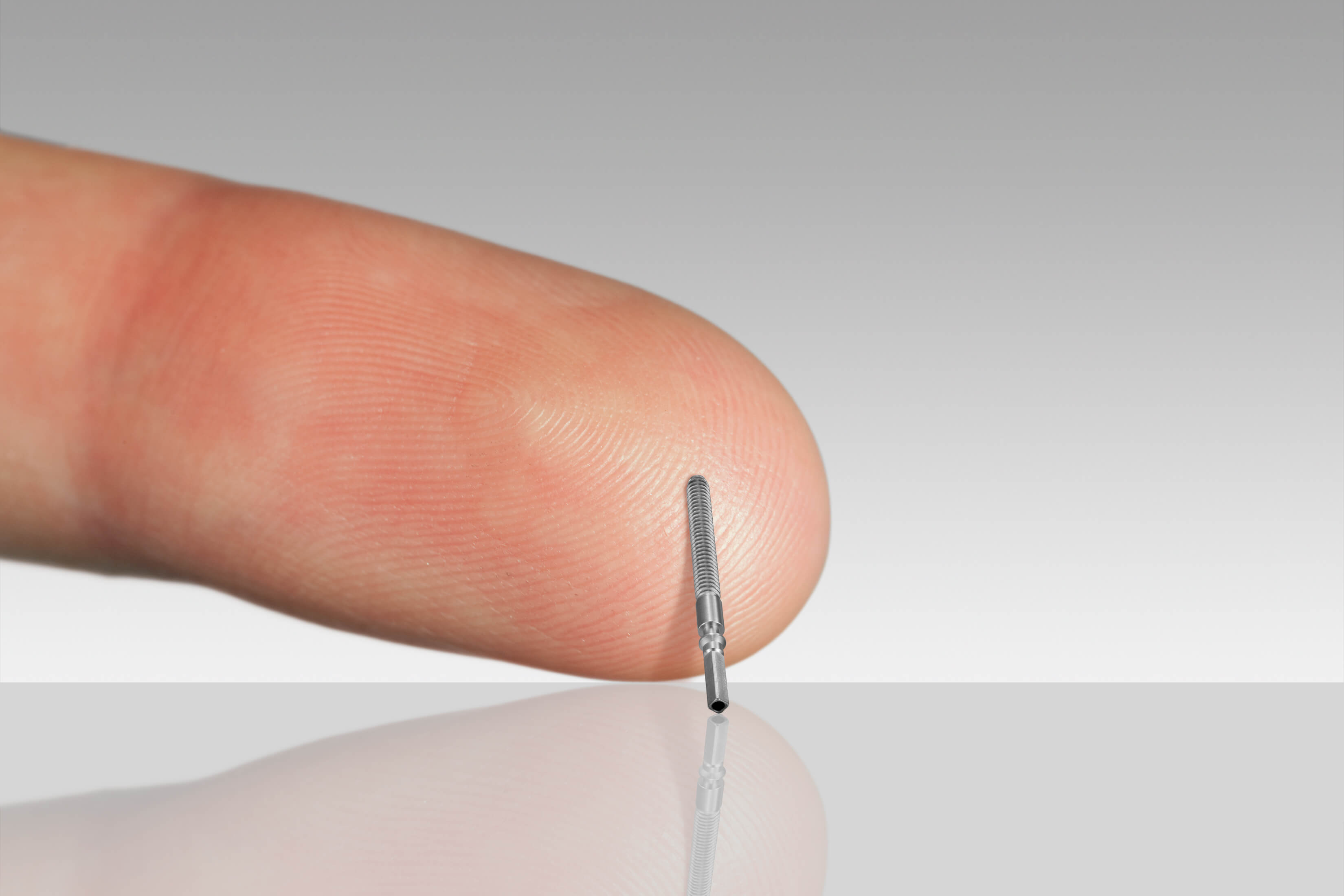

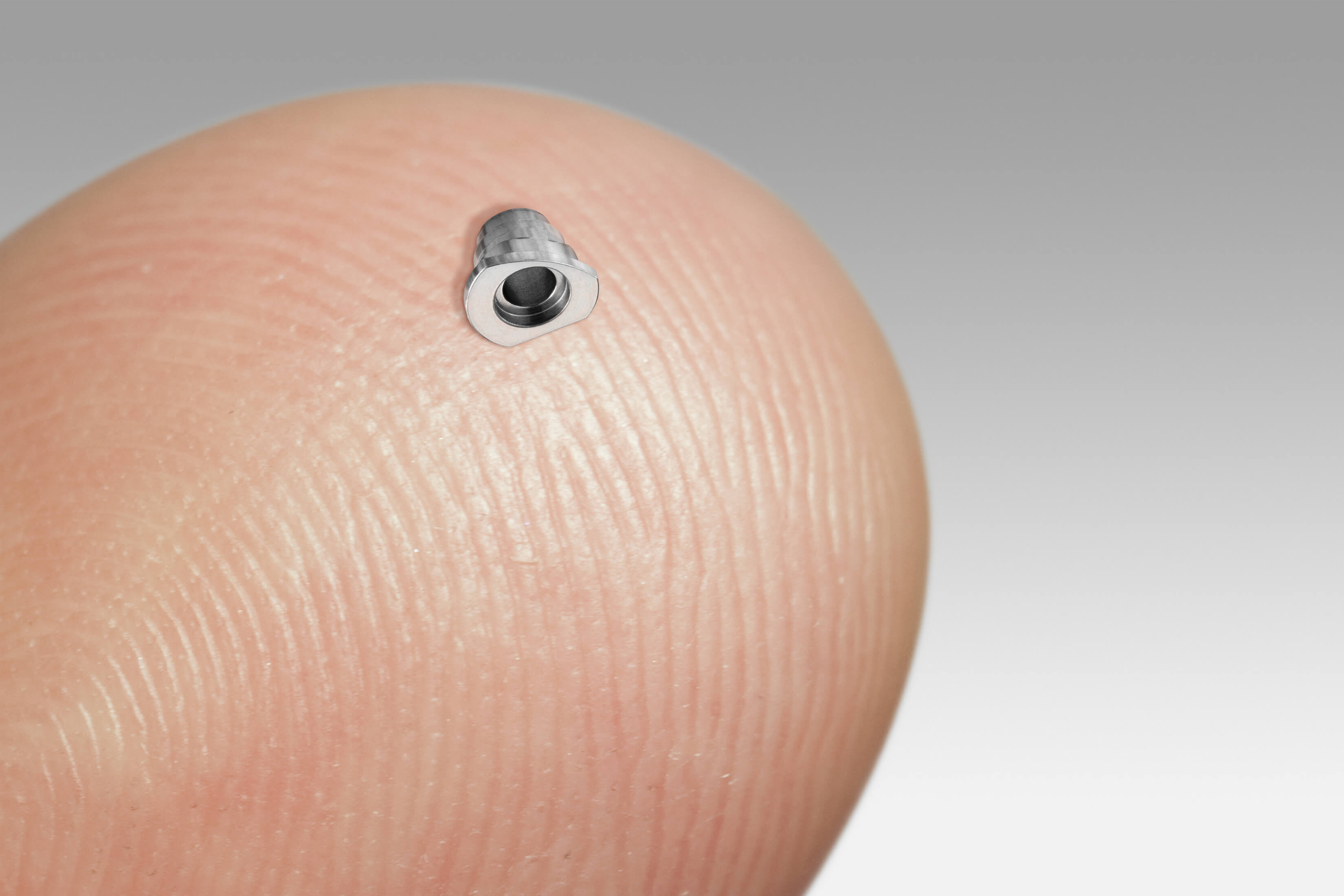

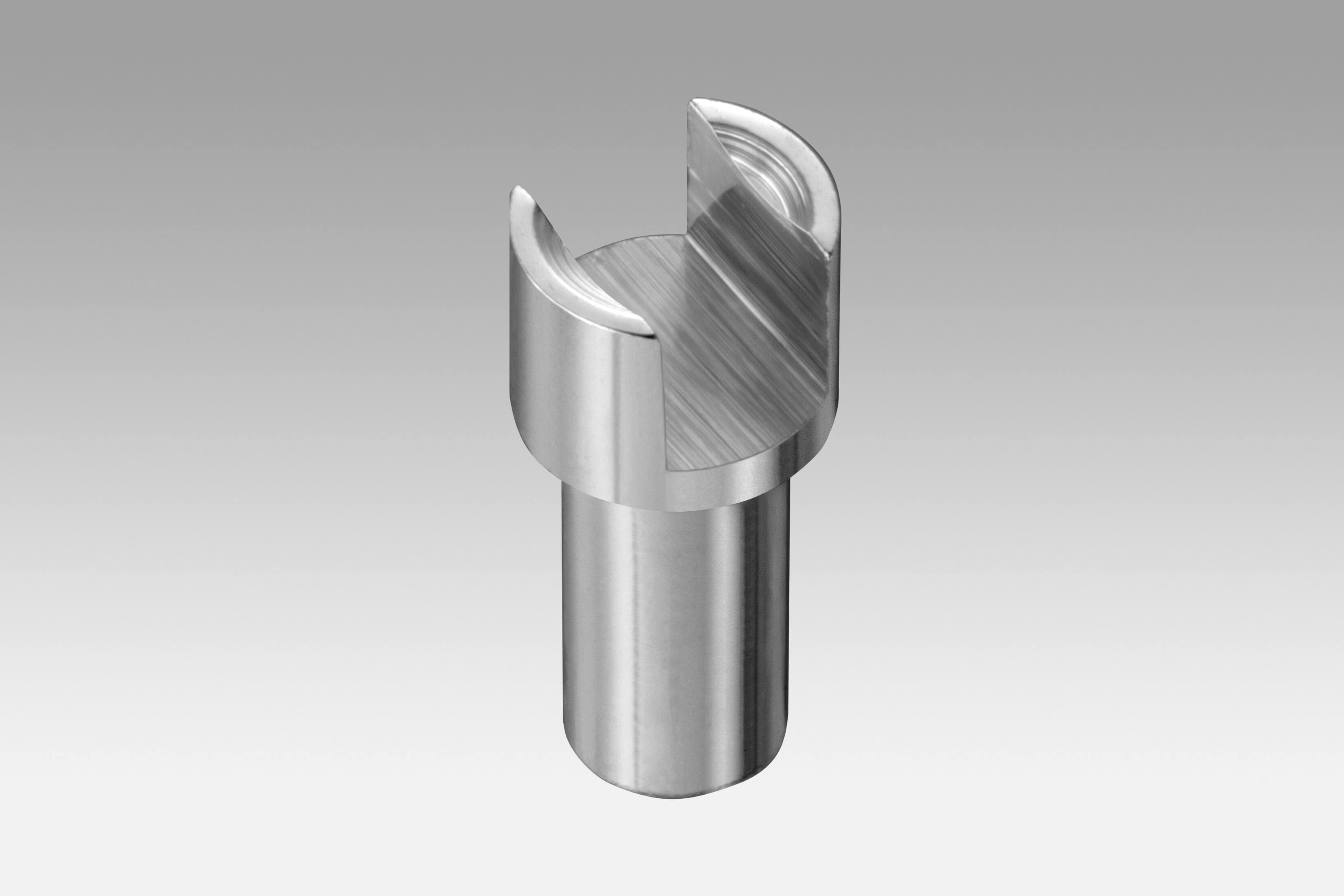

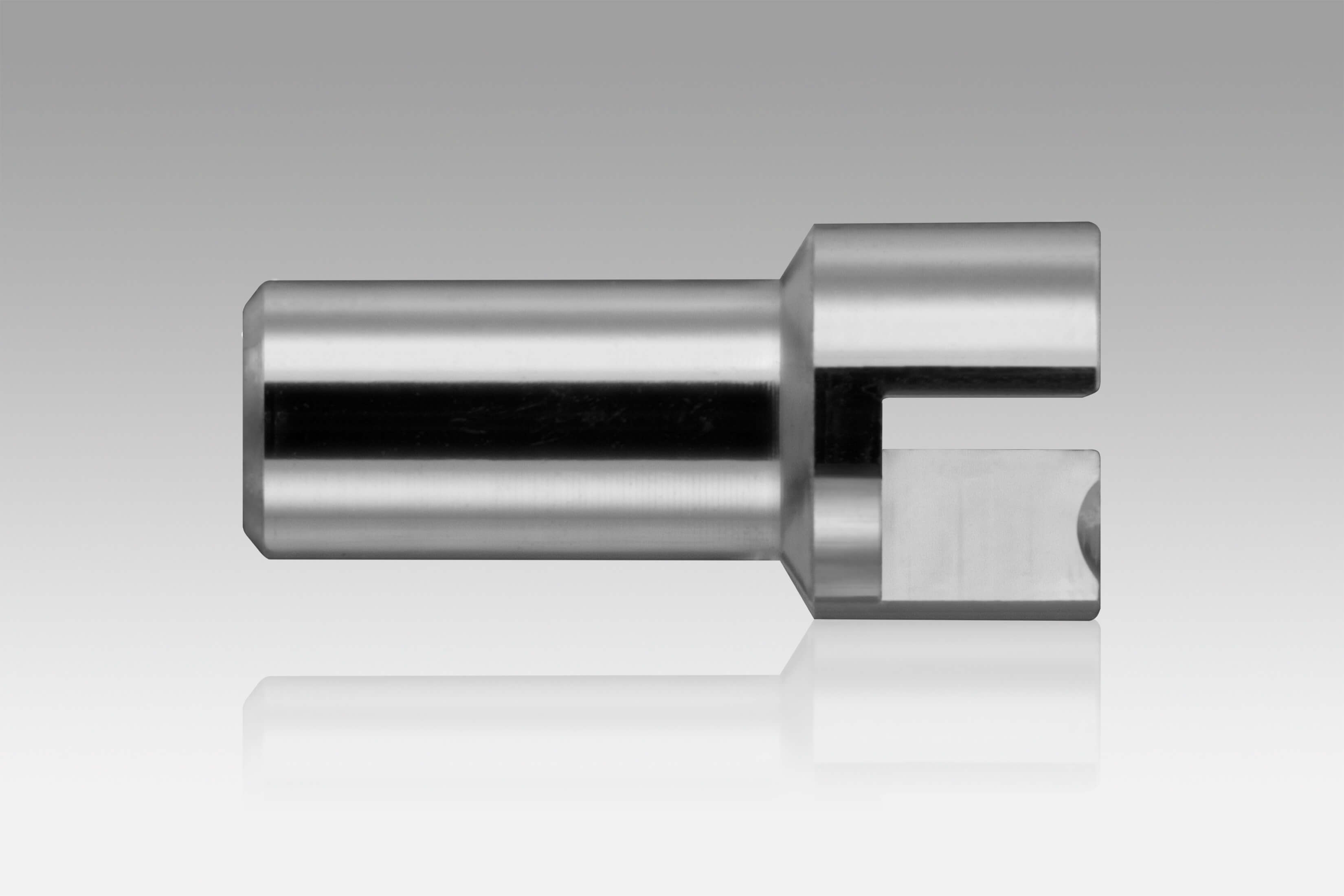

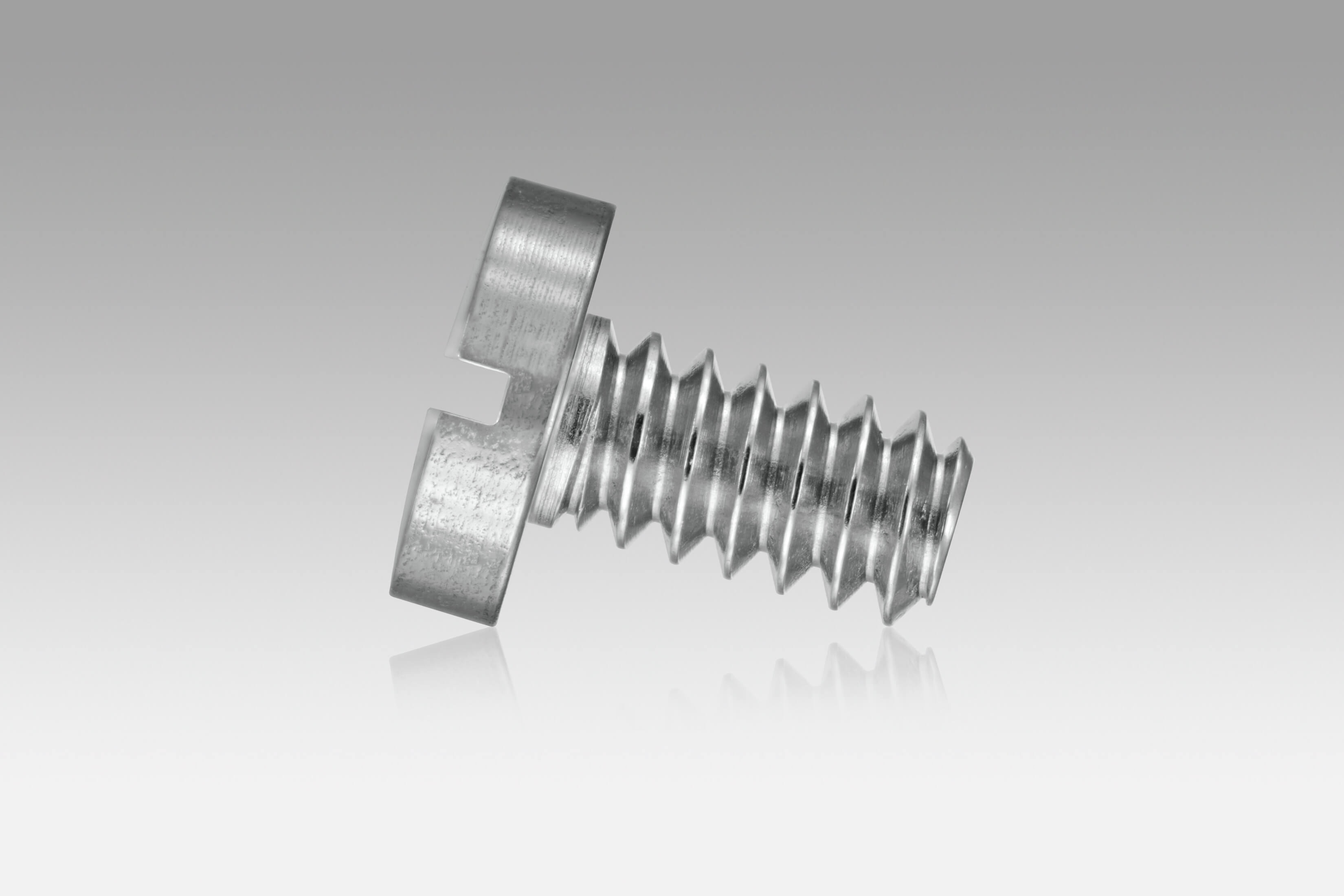

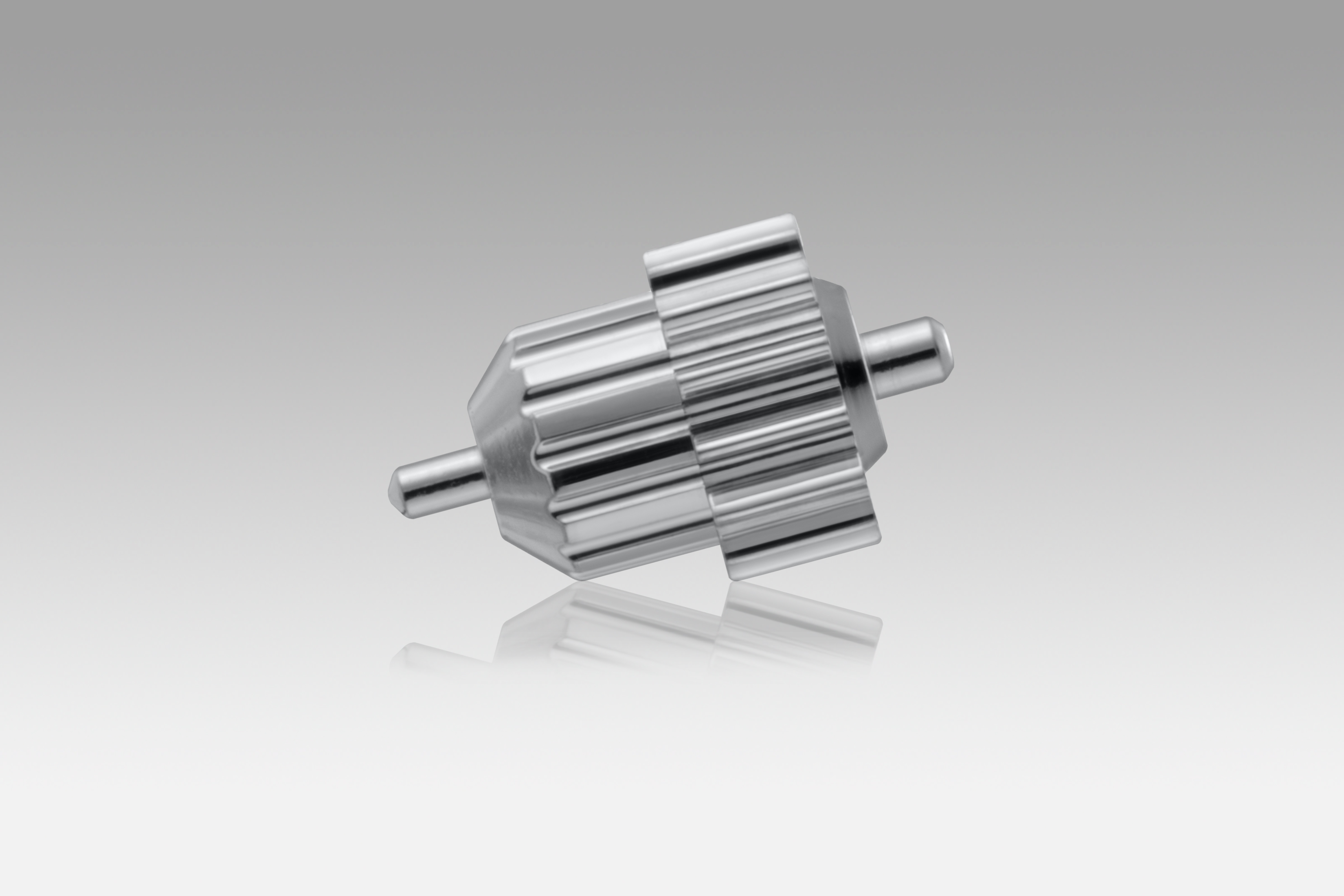

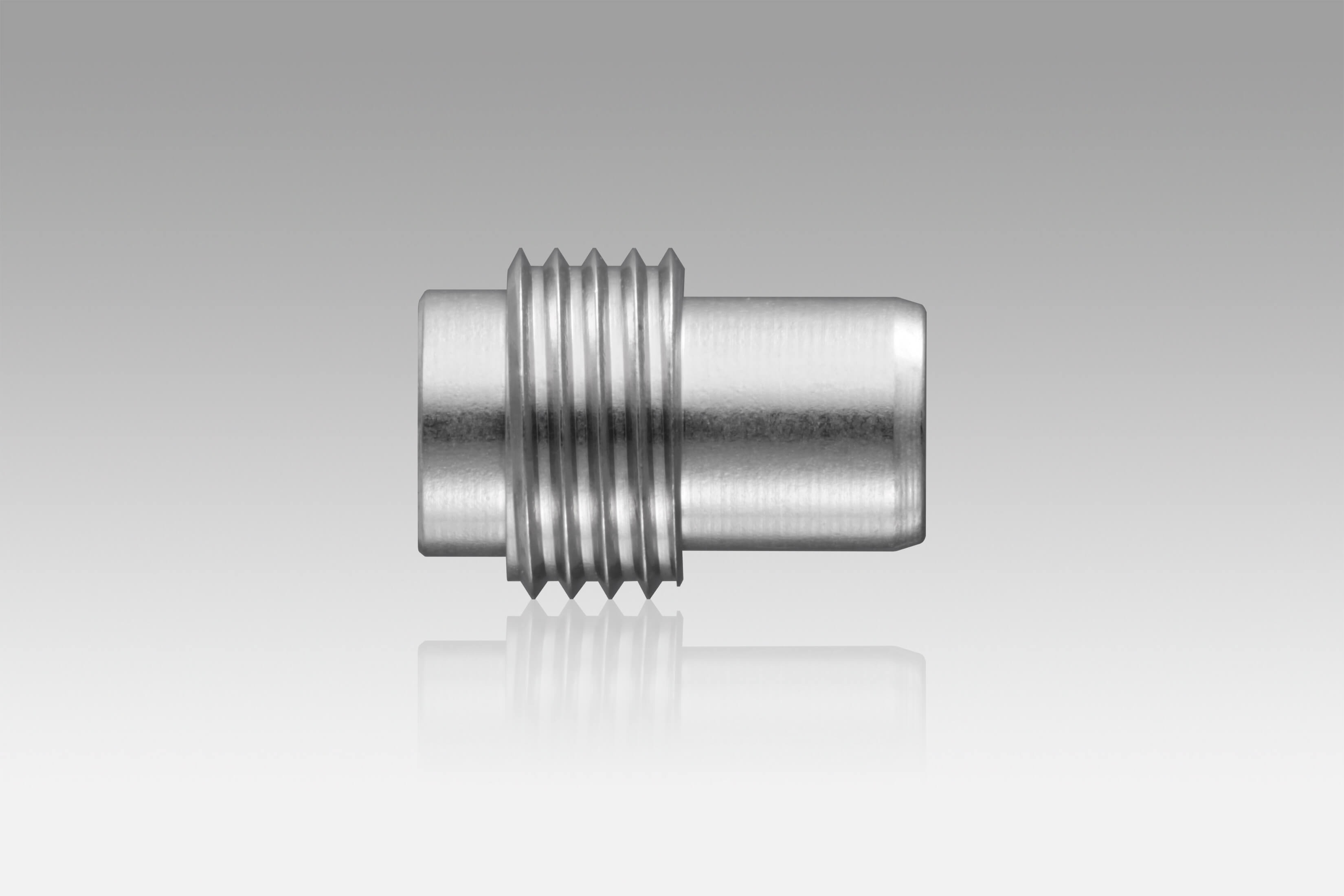

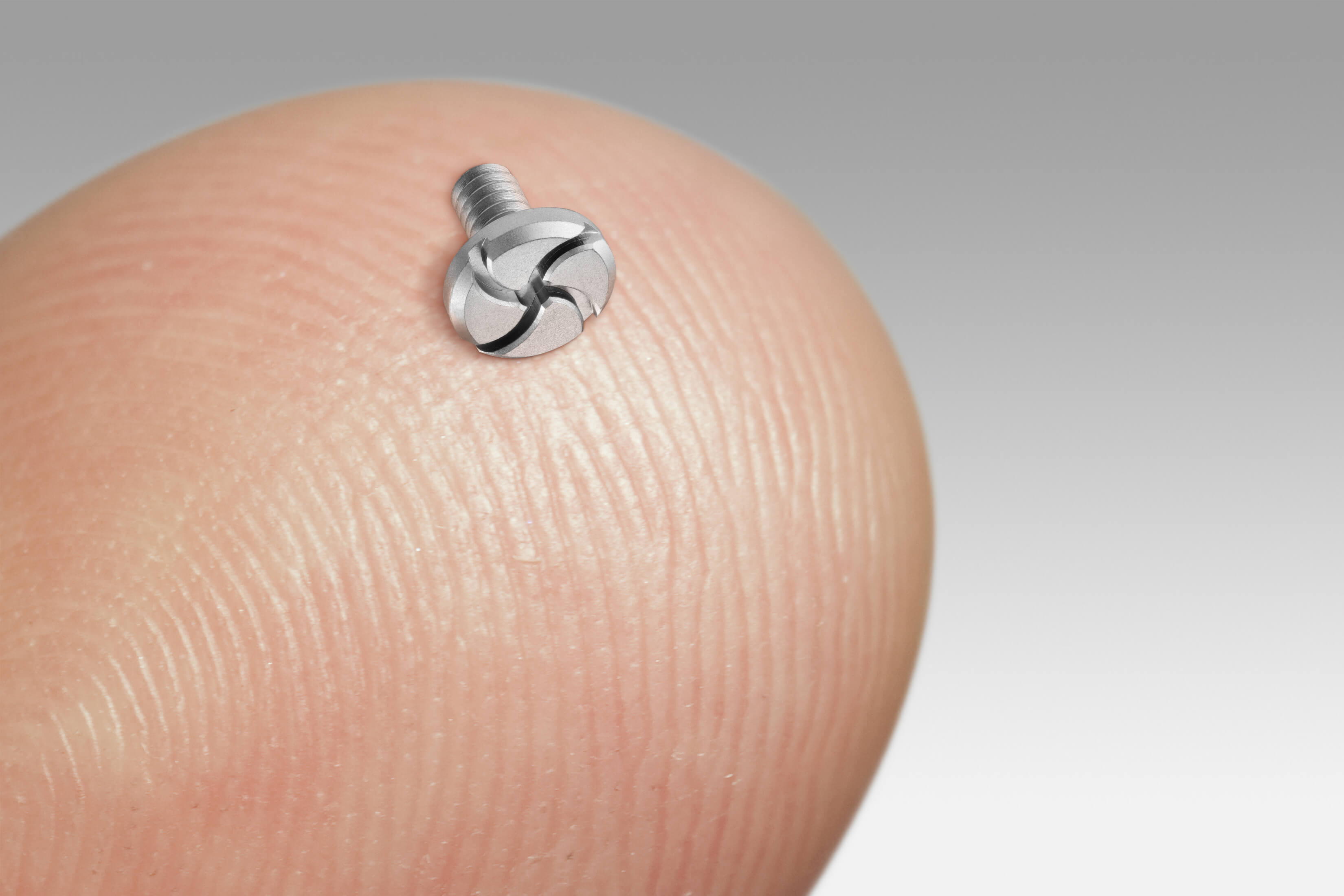

Precision turned watchmaking components includes, for example:

- milling

- drilling

- thread-whirling/tapping or threading

- hobbing

These operations are carried out simultaneously on the precision turning machine.

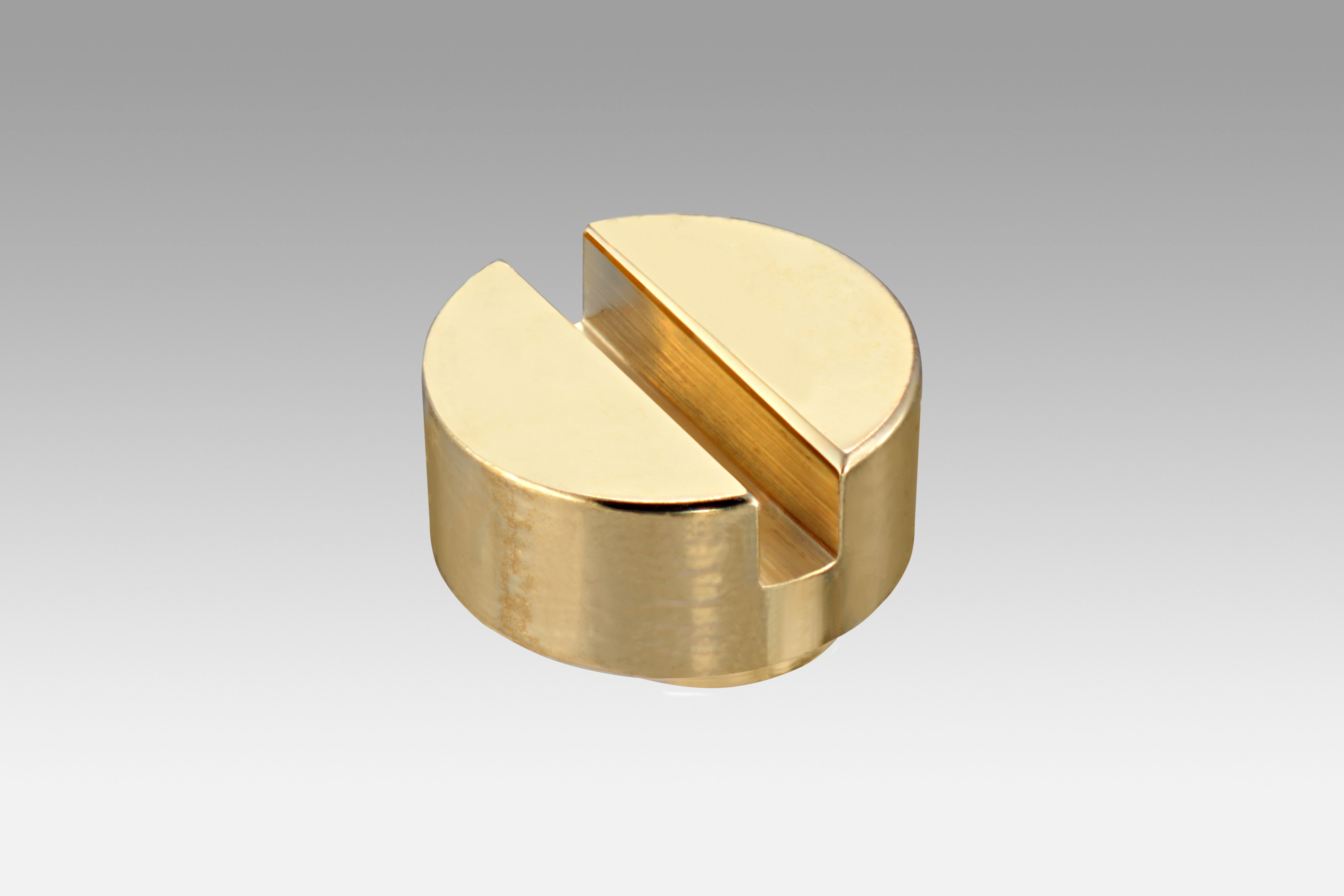

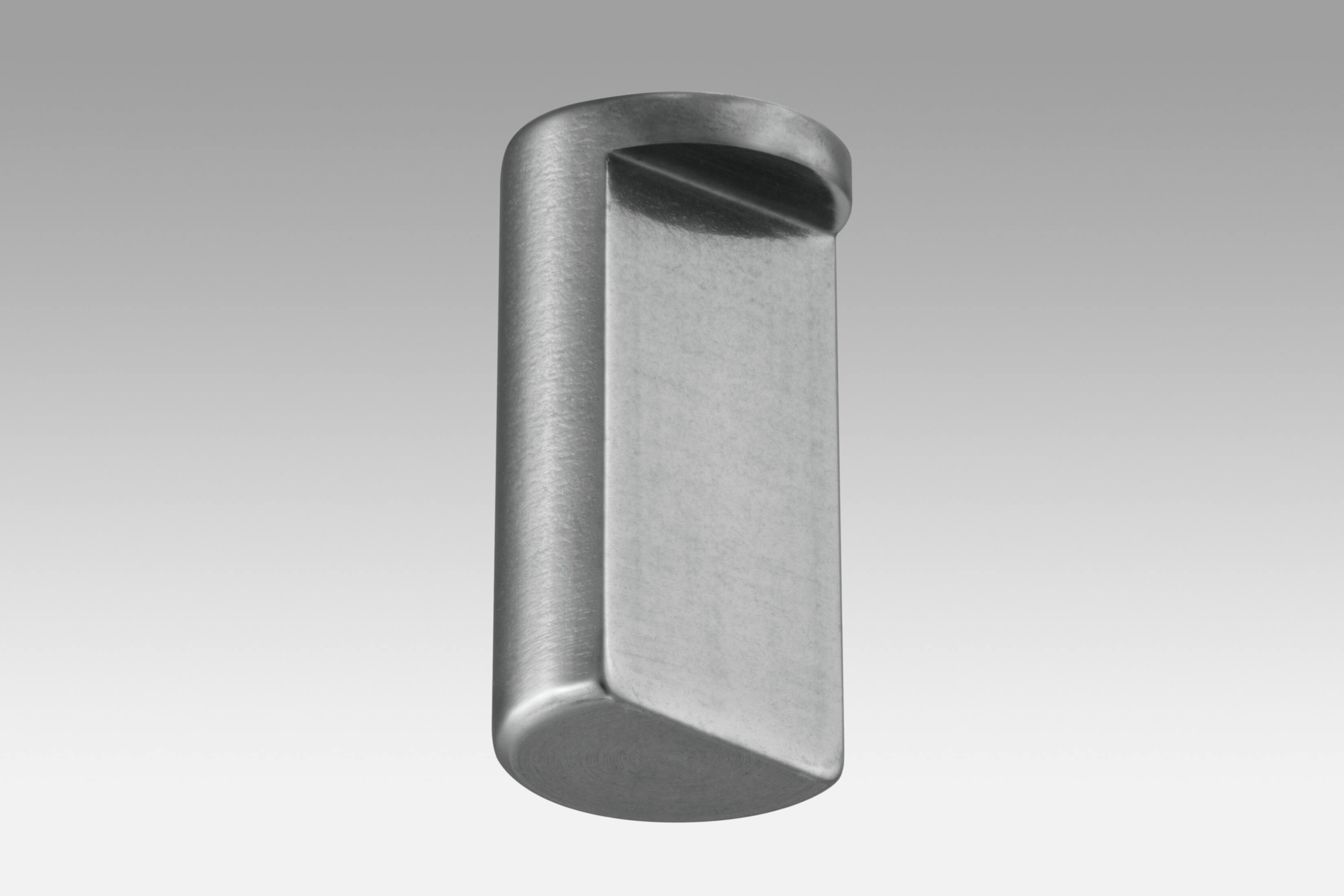

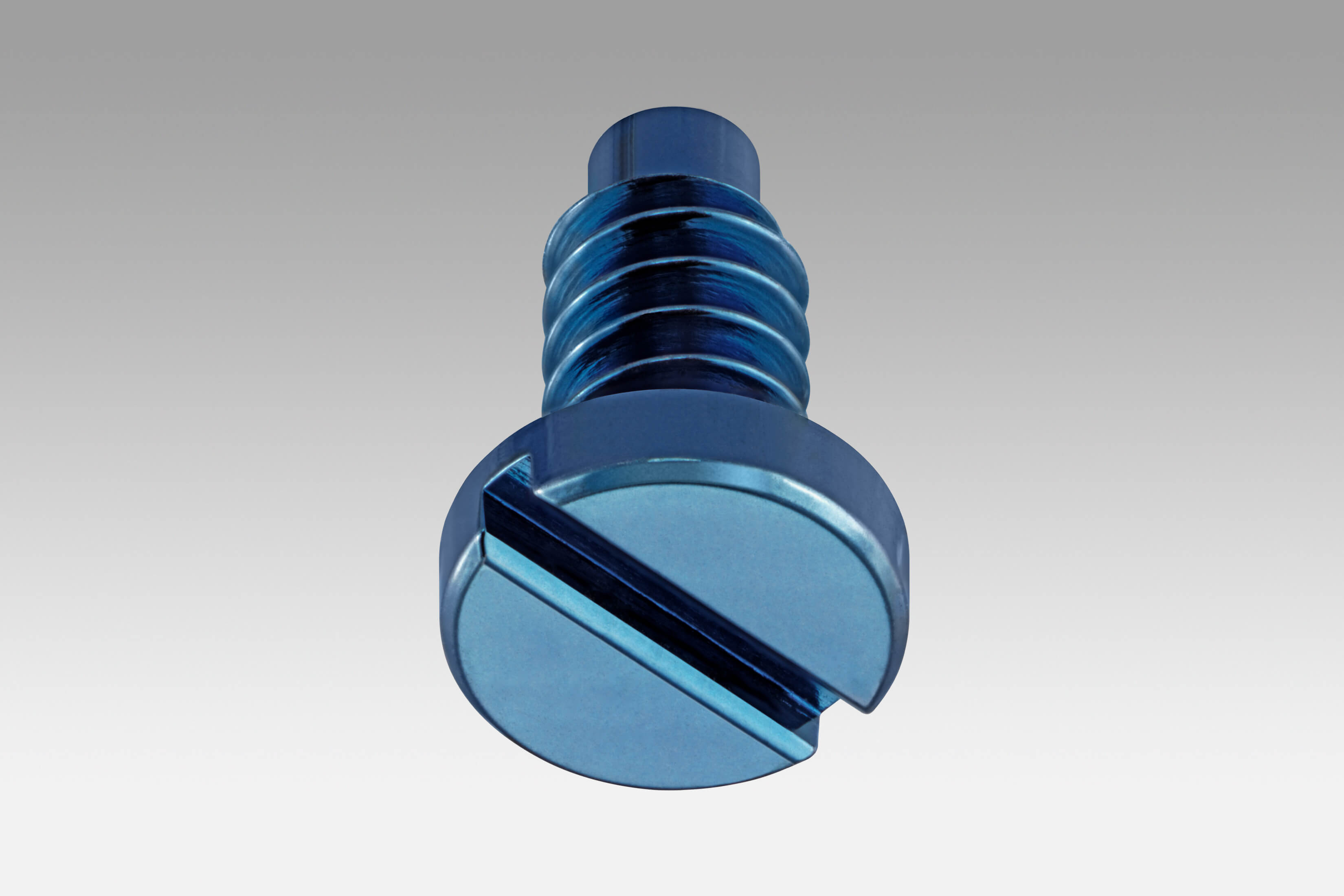

The functional characteristics and the aesthetic aspect – key elements in the luxury watchmaking industry – are achieved using different treatments and/or finishing operations:

- heat treatments

- micro-polishing

- rolling

- polishing/black polishing/mirror polishing

- galvanic treatments: nickel plating, gold plating

- bluing

- sand-/ micro-blasting

- decorations (sunray polishing)

We carry out some of these processes on our own premises, while the rest are subcontracted to qualified partners with whom we work closely.

Customised services on request

To complete the rigorous controls during production (SPC), our team of engineers has developed automatic machines for measuring watchmaking micro-parts, enabling operations such as:

- full dimensional inspection

- sorting into categories according to dimensions and/or tolerances

Other innovative technical techniques can still be developed, contact us!

Our culture

The rigour required by the IATF 16949 automotive standard in the control of our processes has enabled us to expand our business into the watchmaking market, where precision and excellence are core values.

All our business-related tasks are controlled, documented and centralised by an ERP software, developed in-house. This computerised control enables us to efficiently co-ordinate all our manufacturing processes and to supply parts which are compliant in terms of quality and lead times.

Moreover, particular attention is paid to the well-being and respect of our staff, our partners and the environment. This philosophy is an integral part of our corporate culture.

Benefits for you

| Excellence | The high level of quality you expect ("Swiss Made" requirements)

|

Proactive approach

| We respond systematically as soon as possible

|

Timeliness

| Our high-performance logistics ensure we keep to the delivery lead times

|

Service

| Comprehensive service including finishing and packaging of parts

|

Innovation

| Customized solutions on offer

|

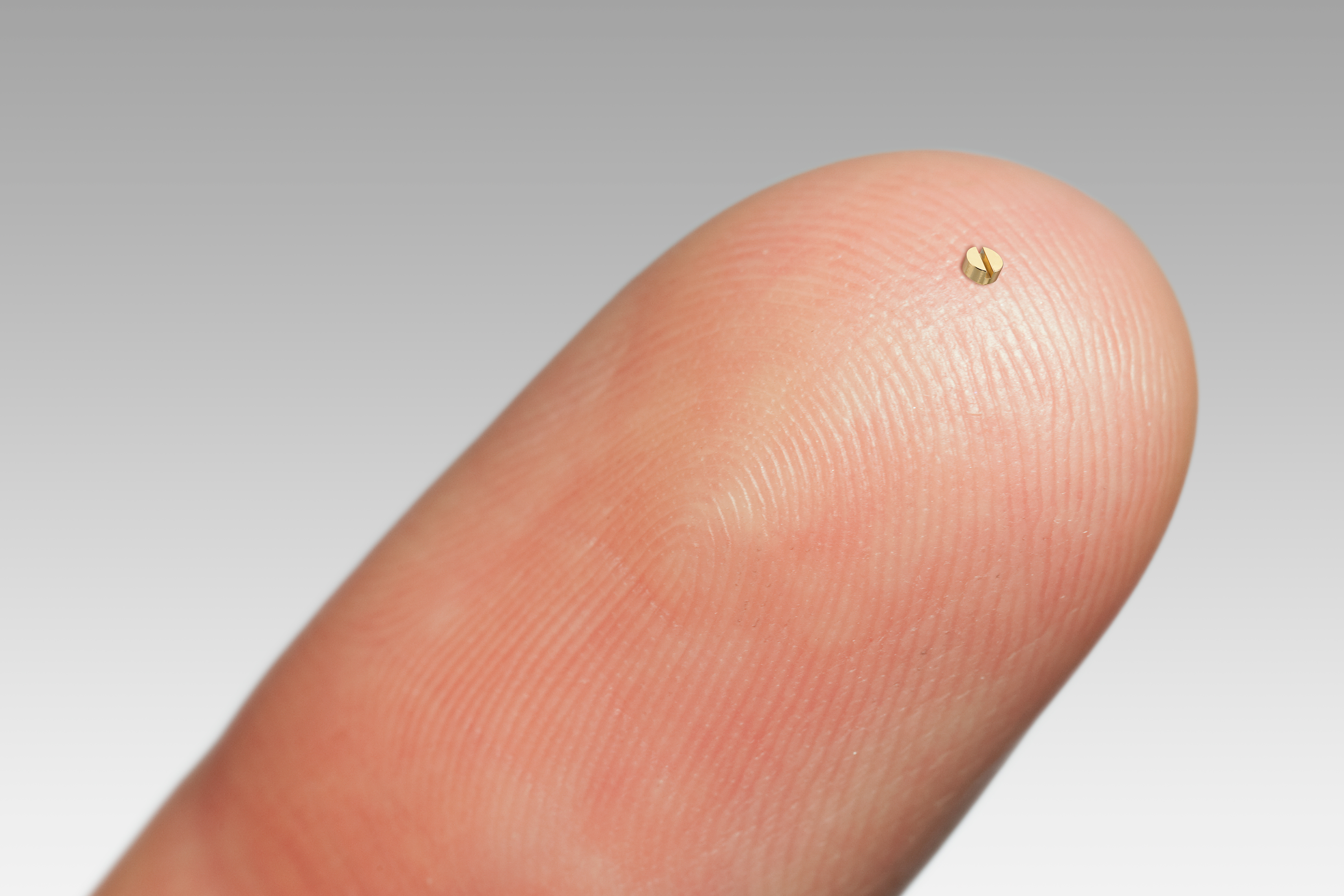

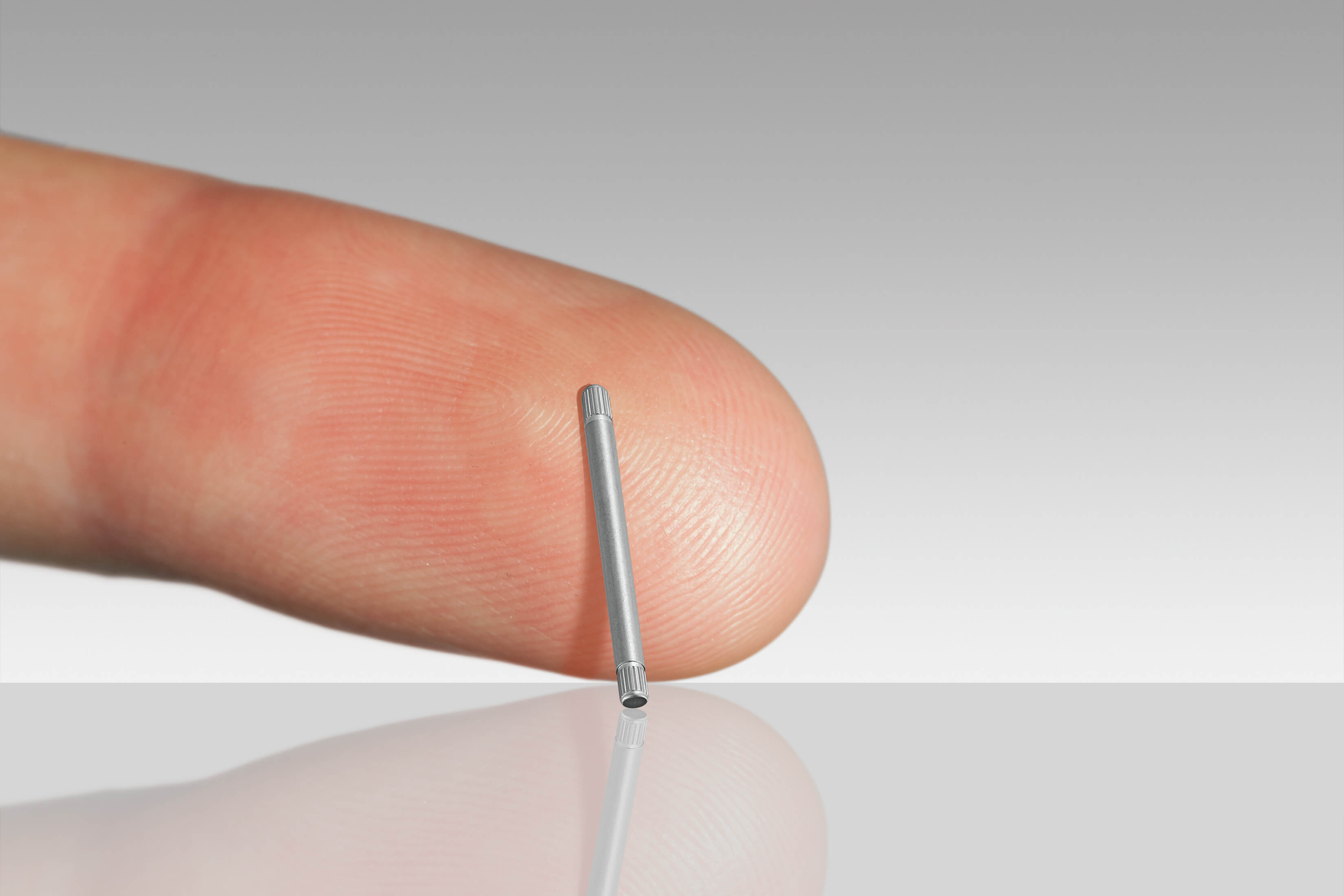

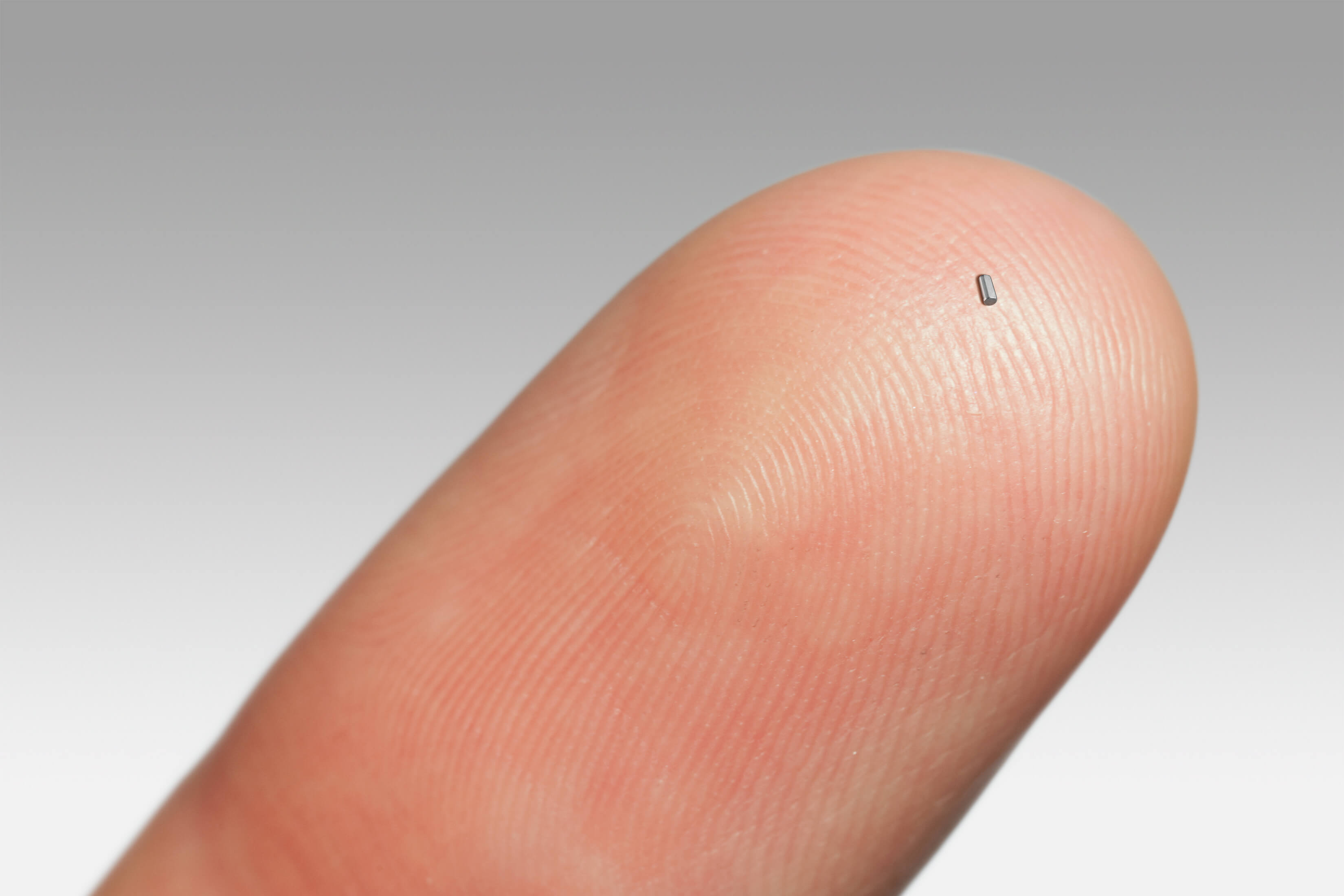

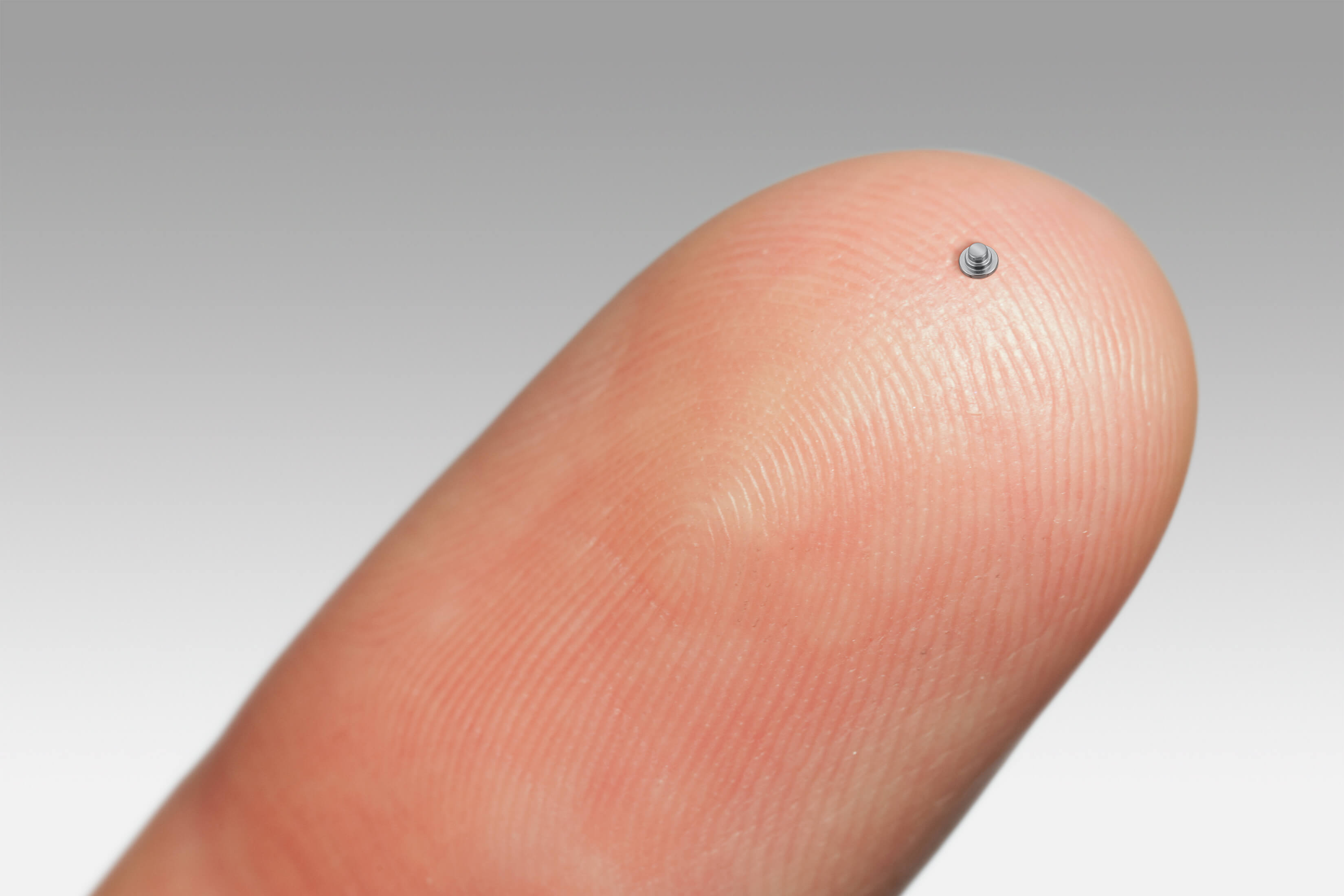

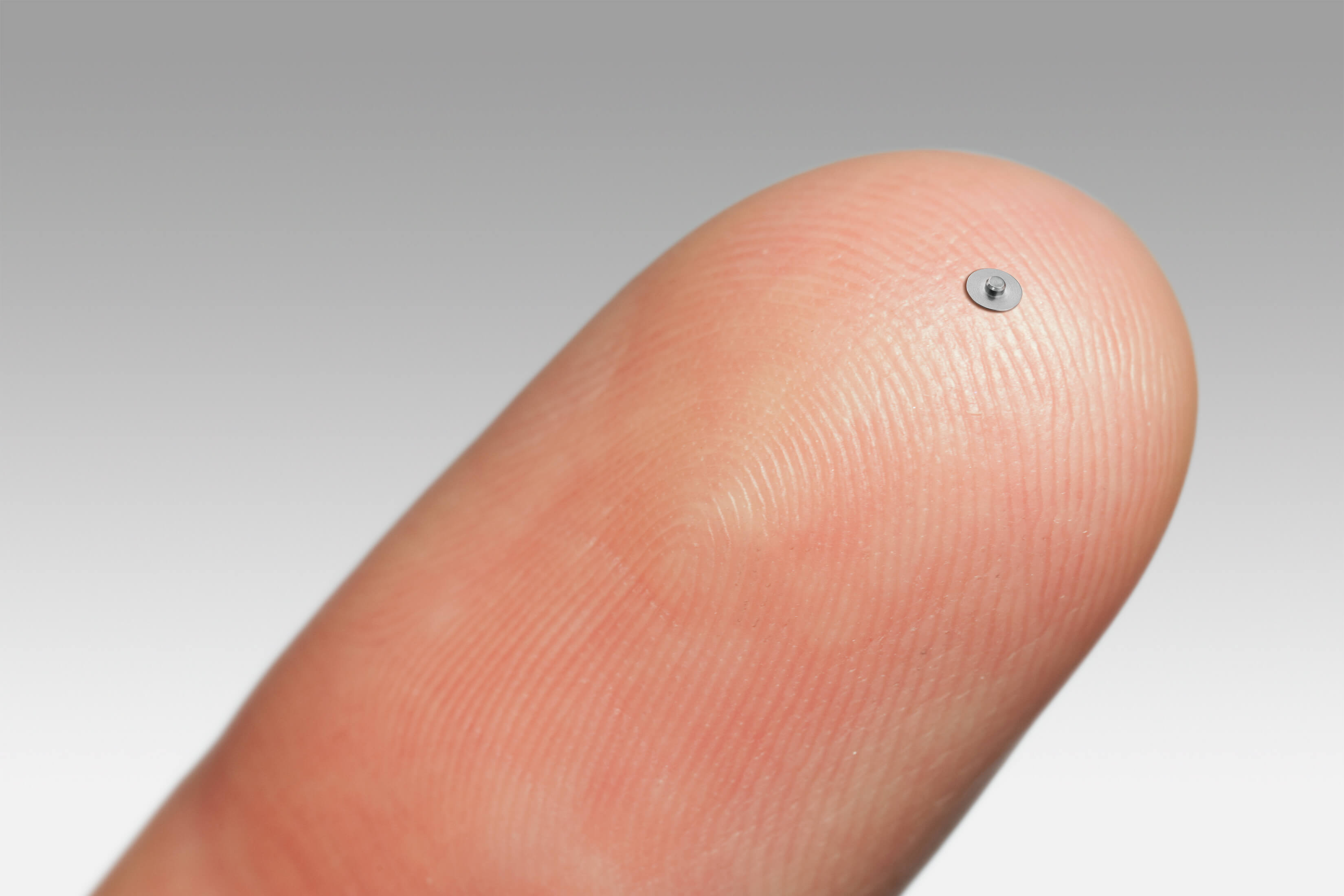

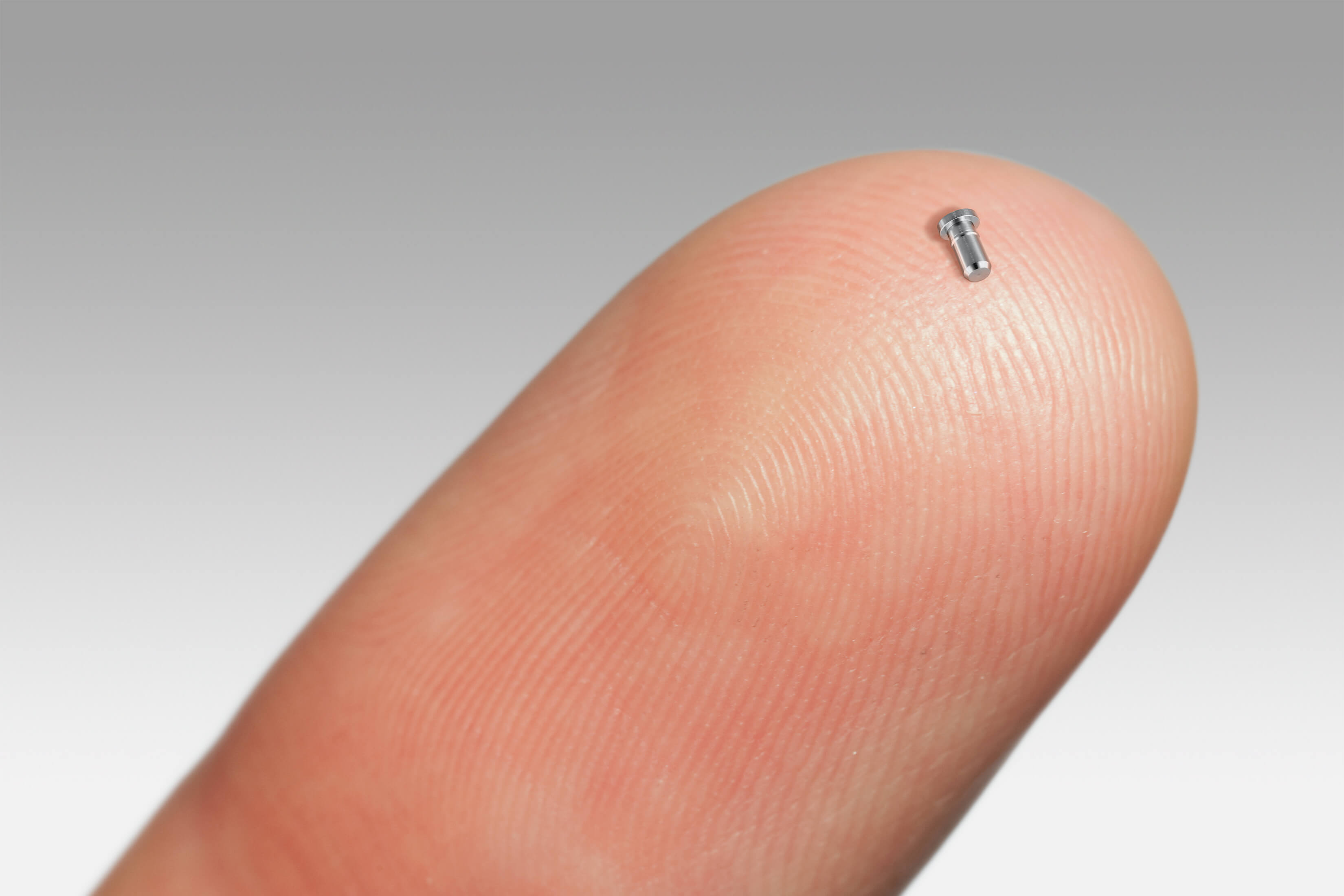

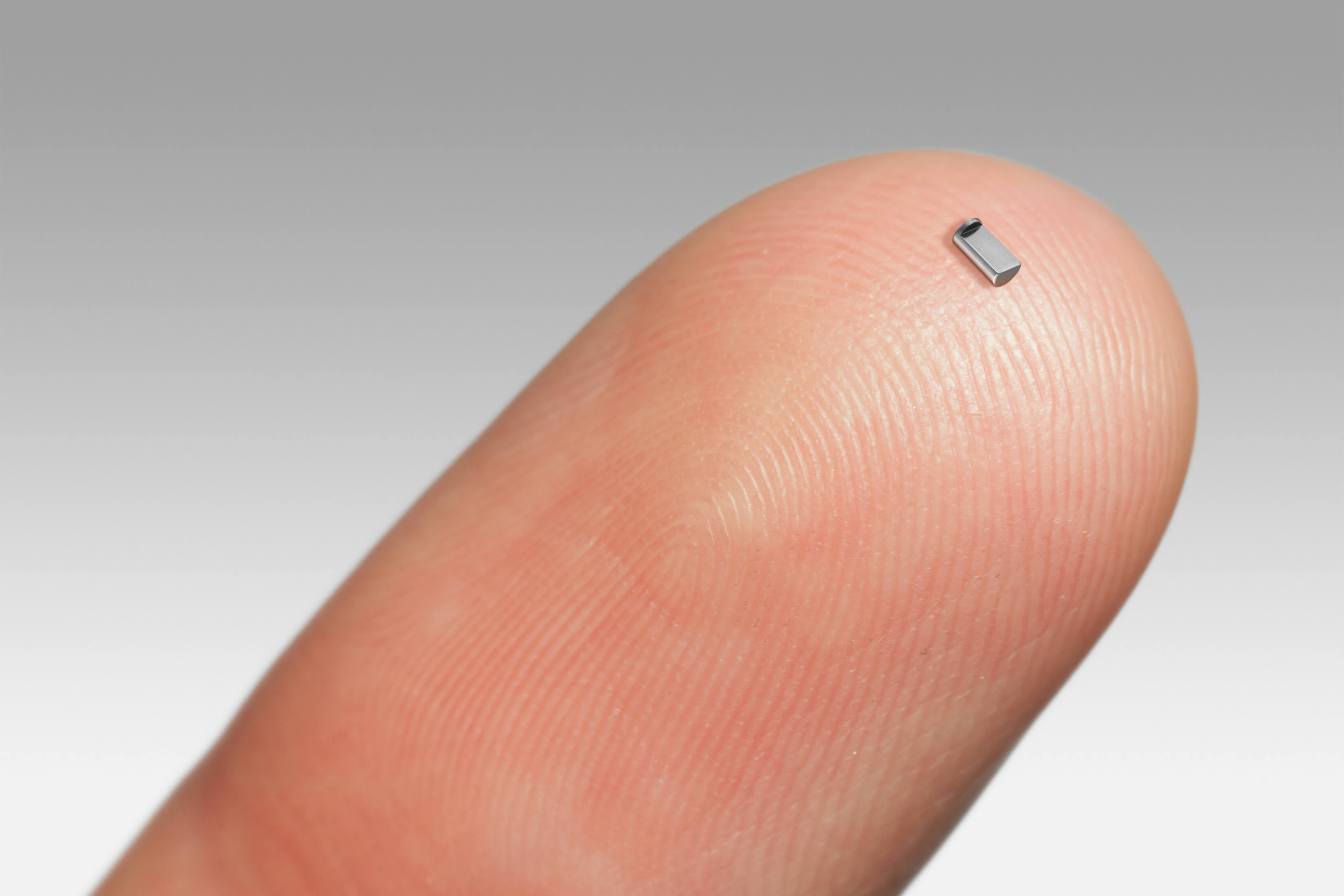

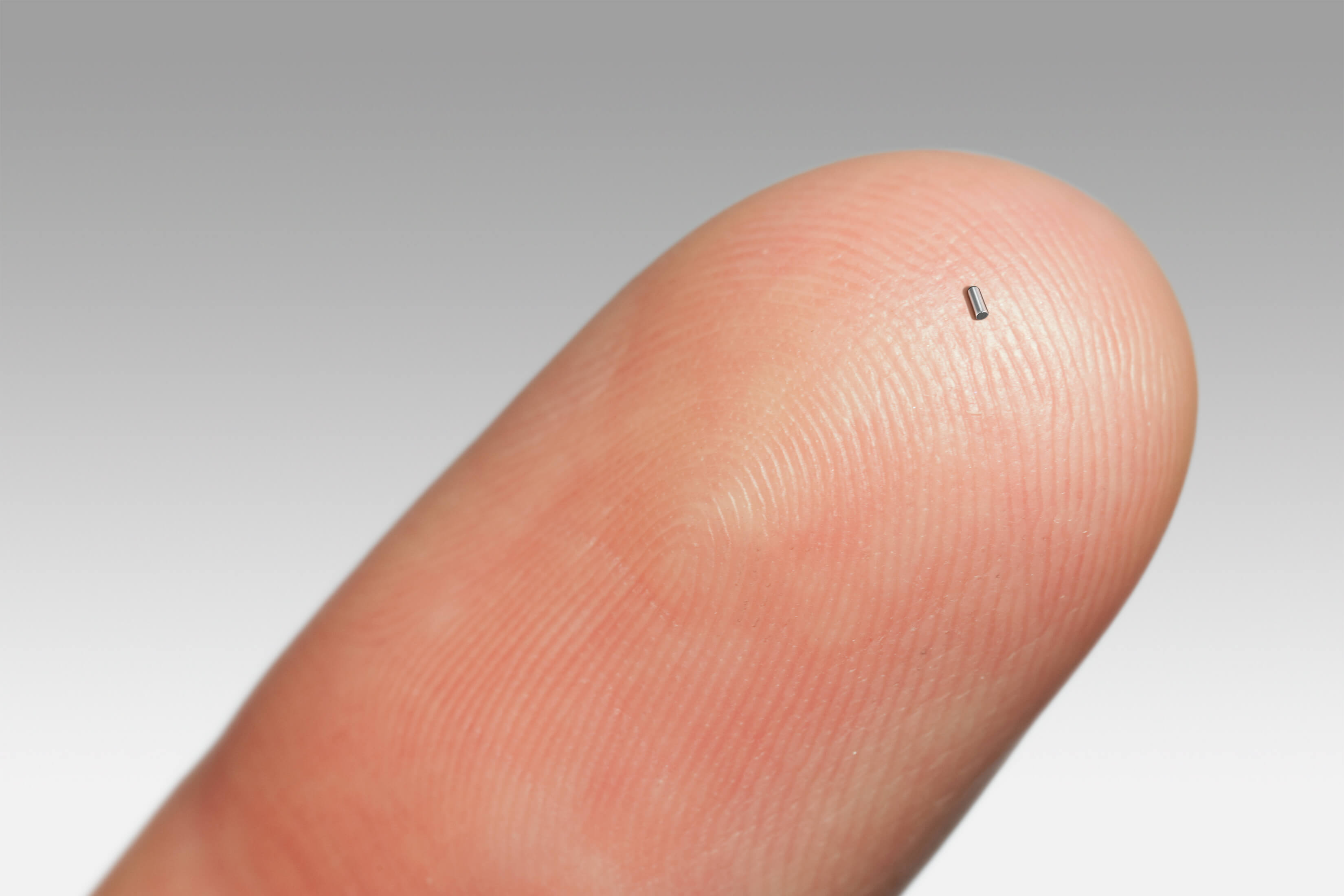

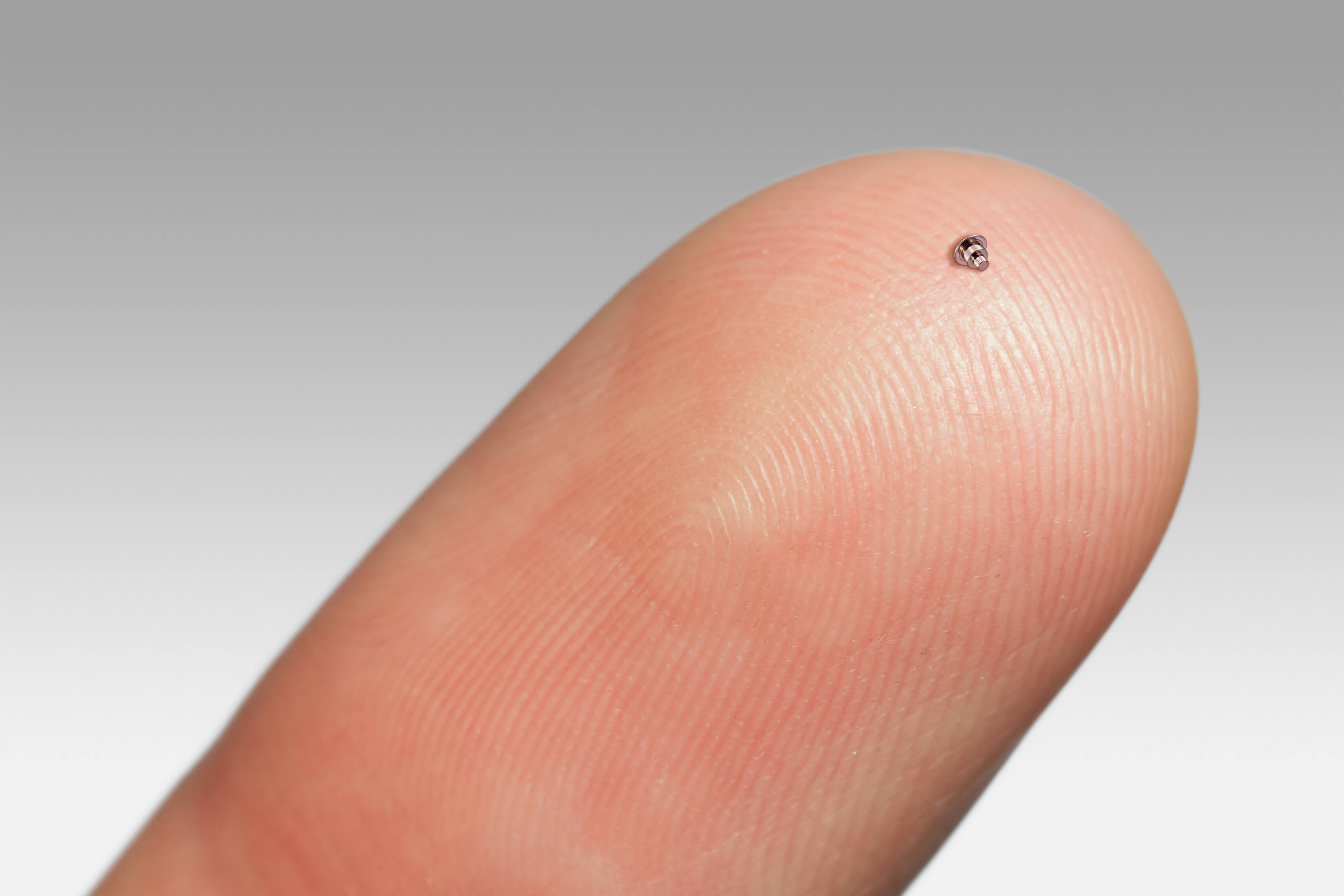

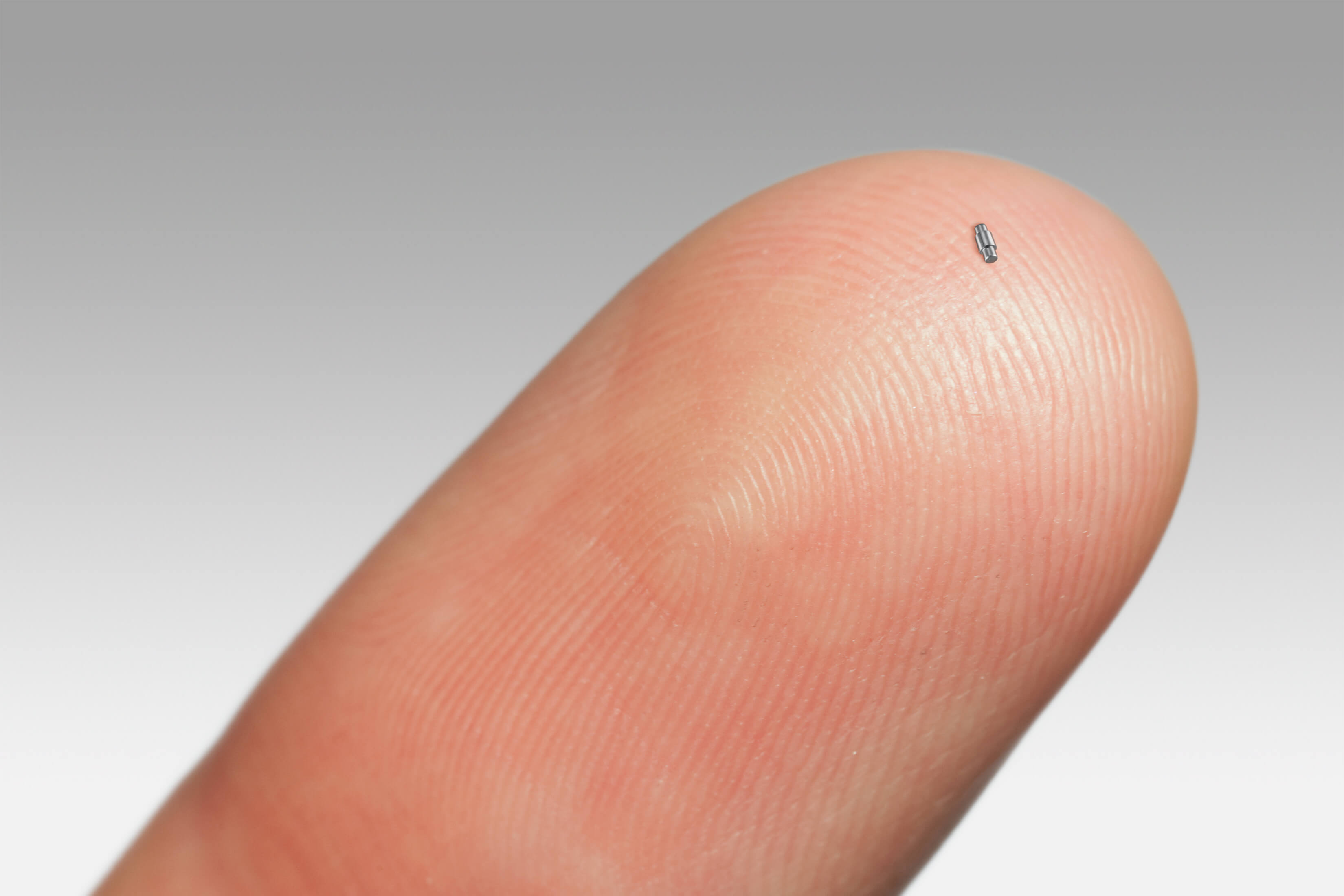

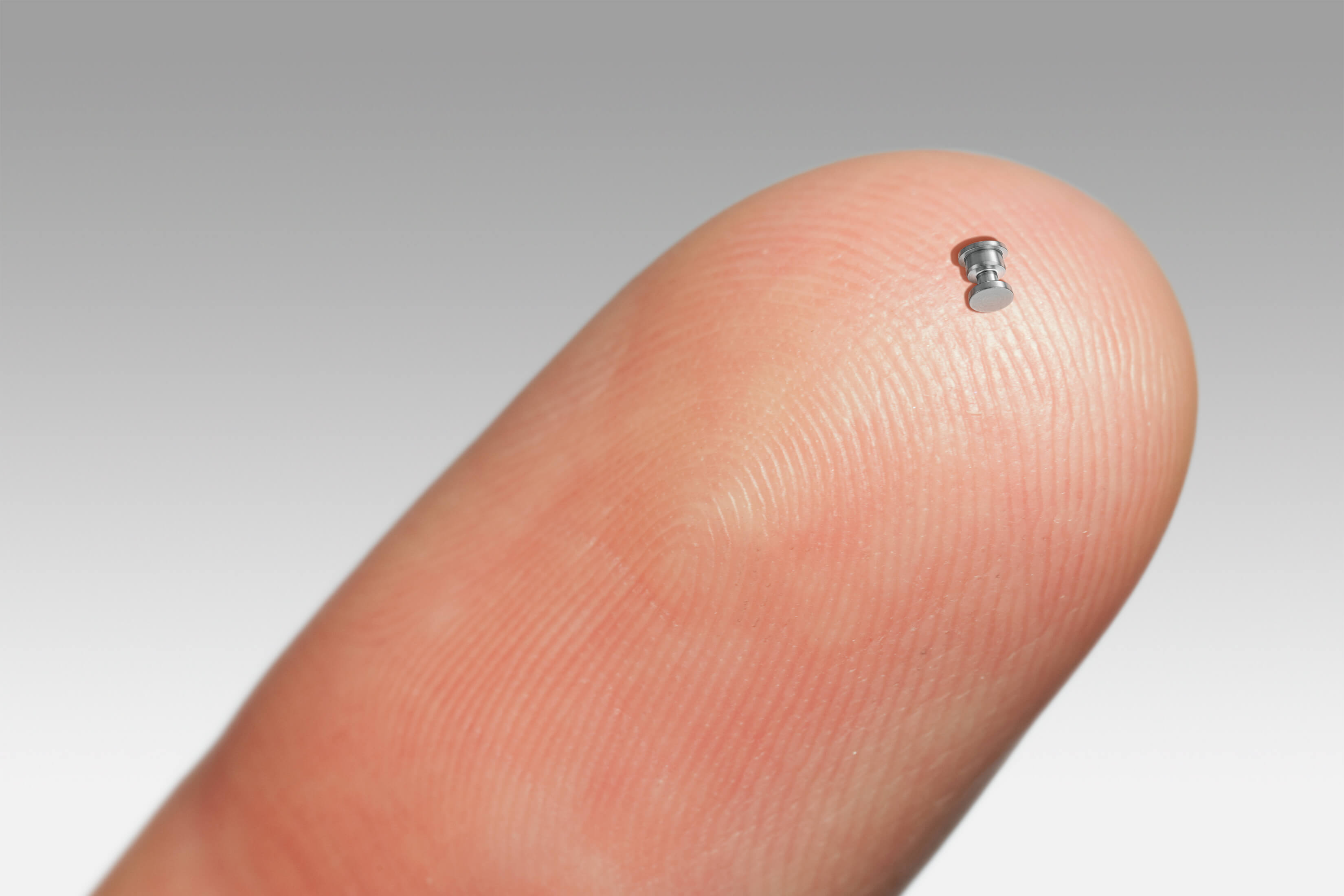

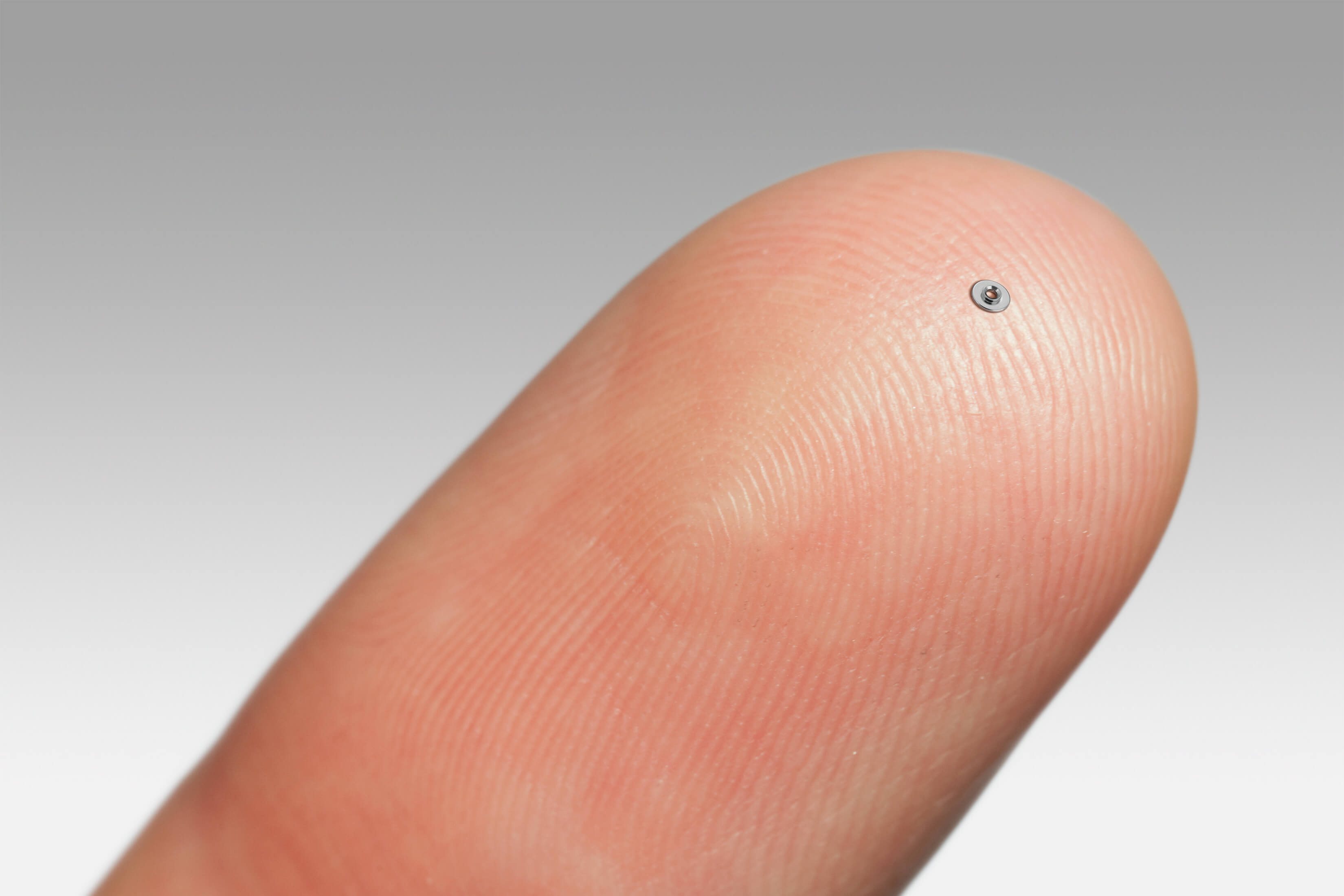

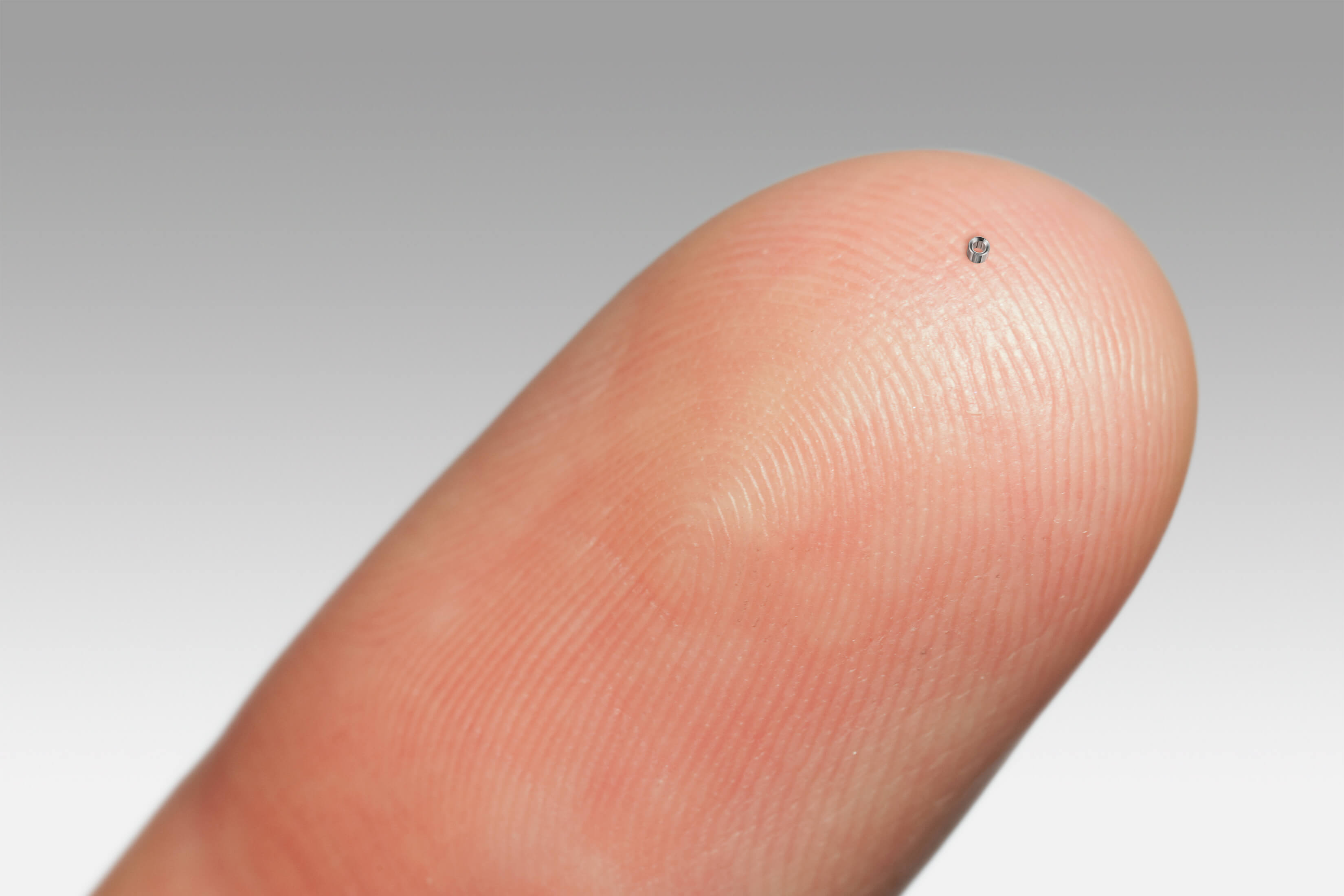

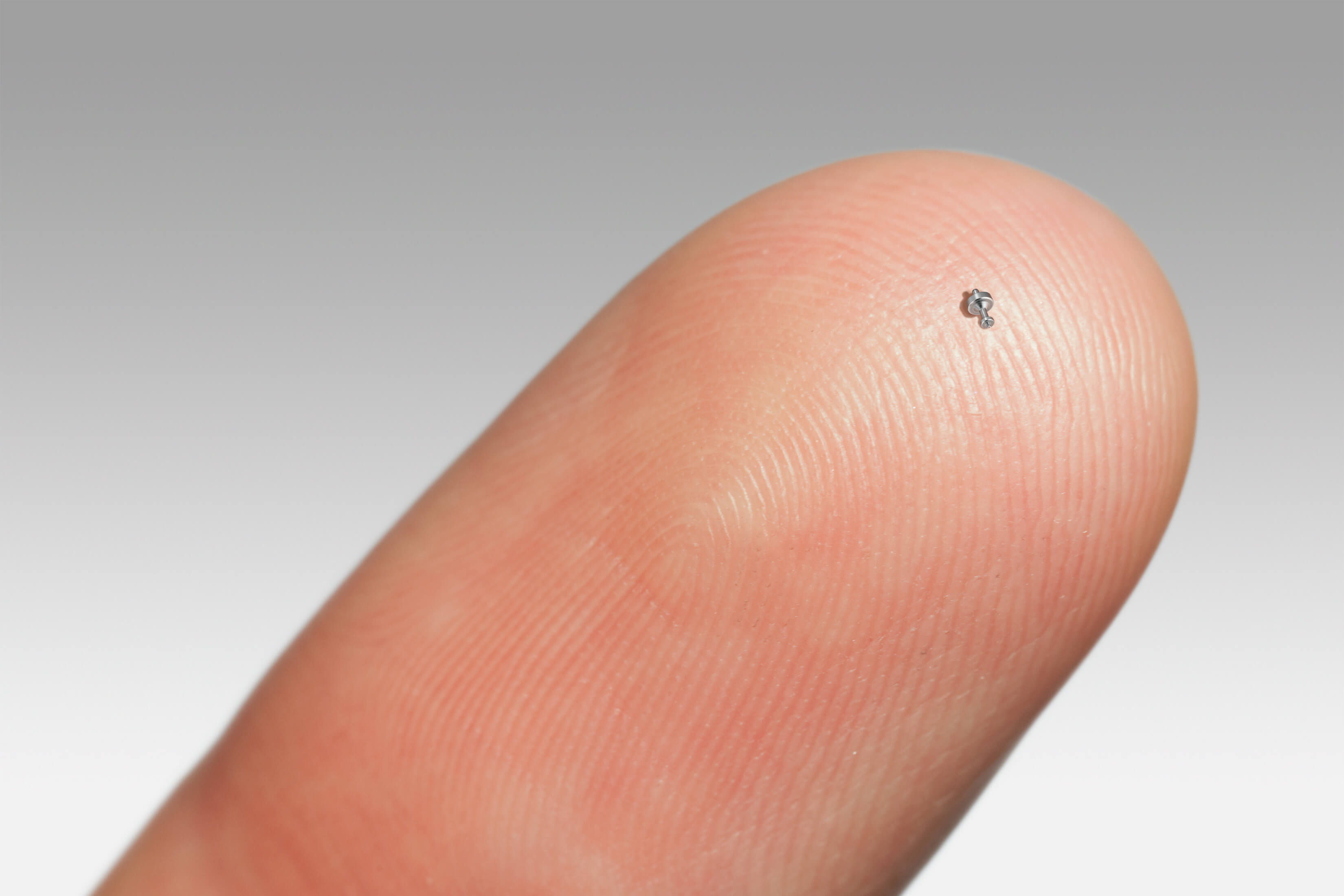

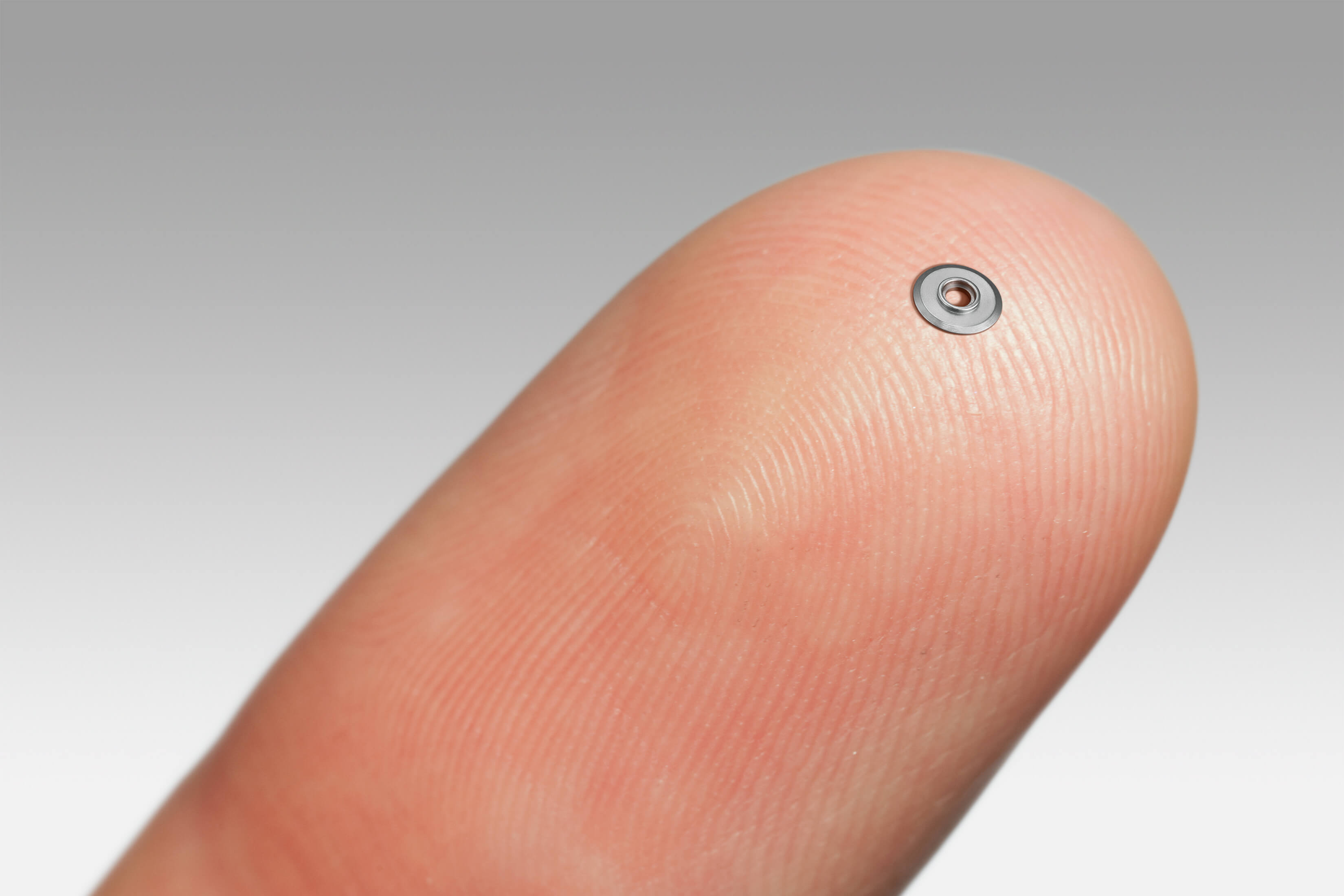

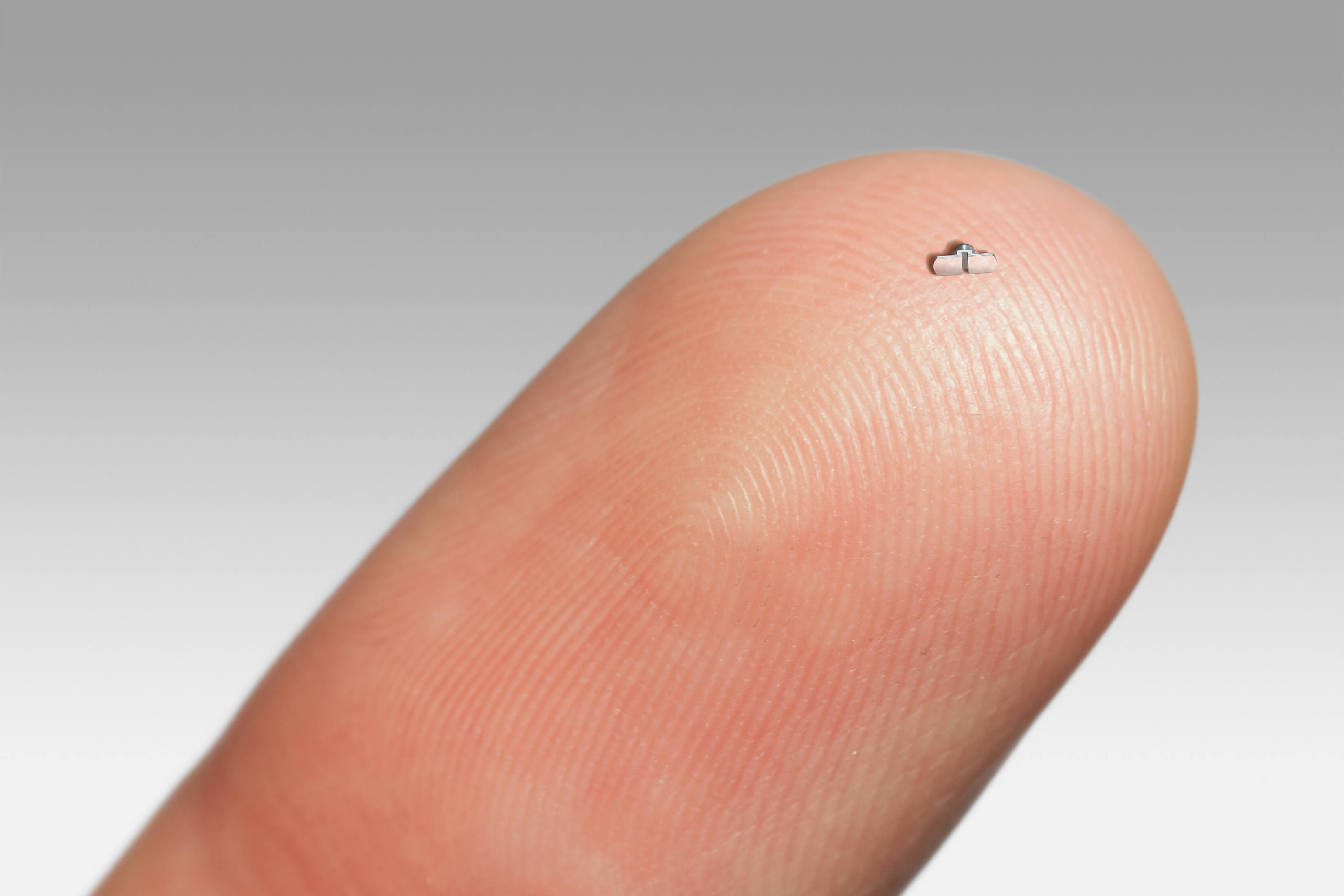

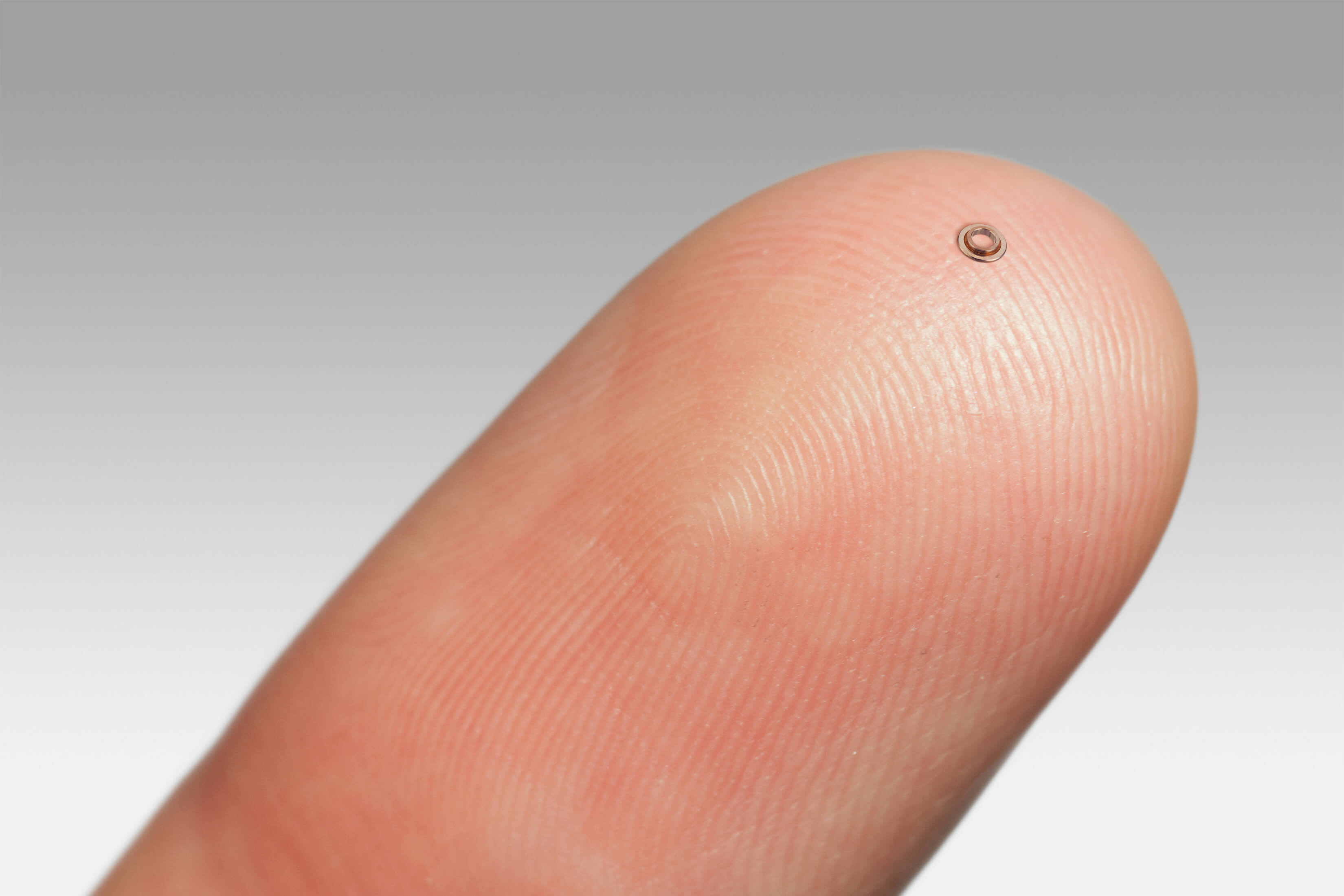

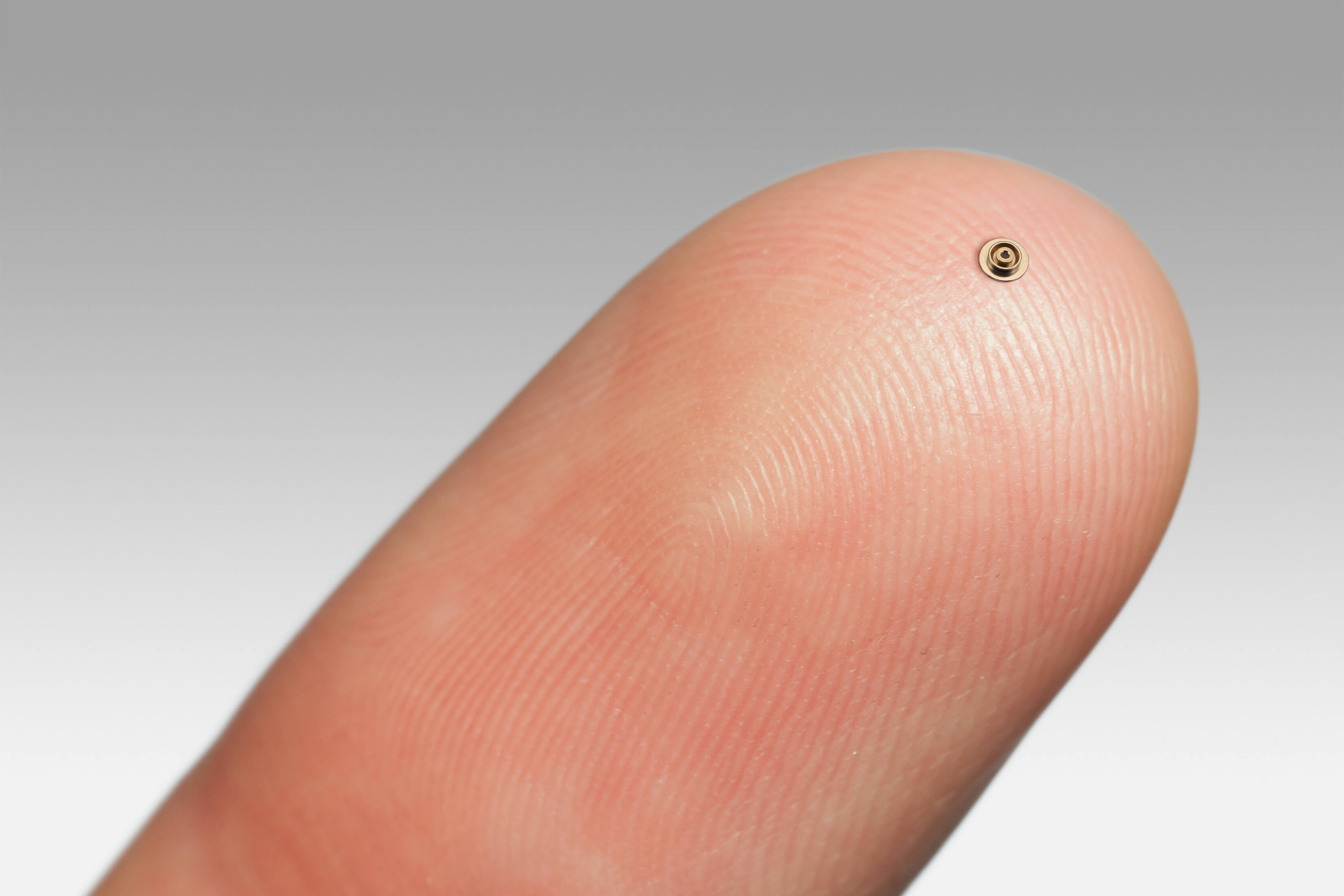

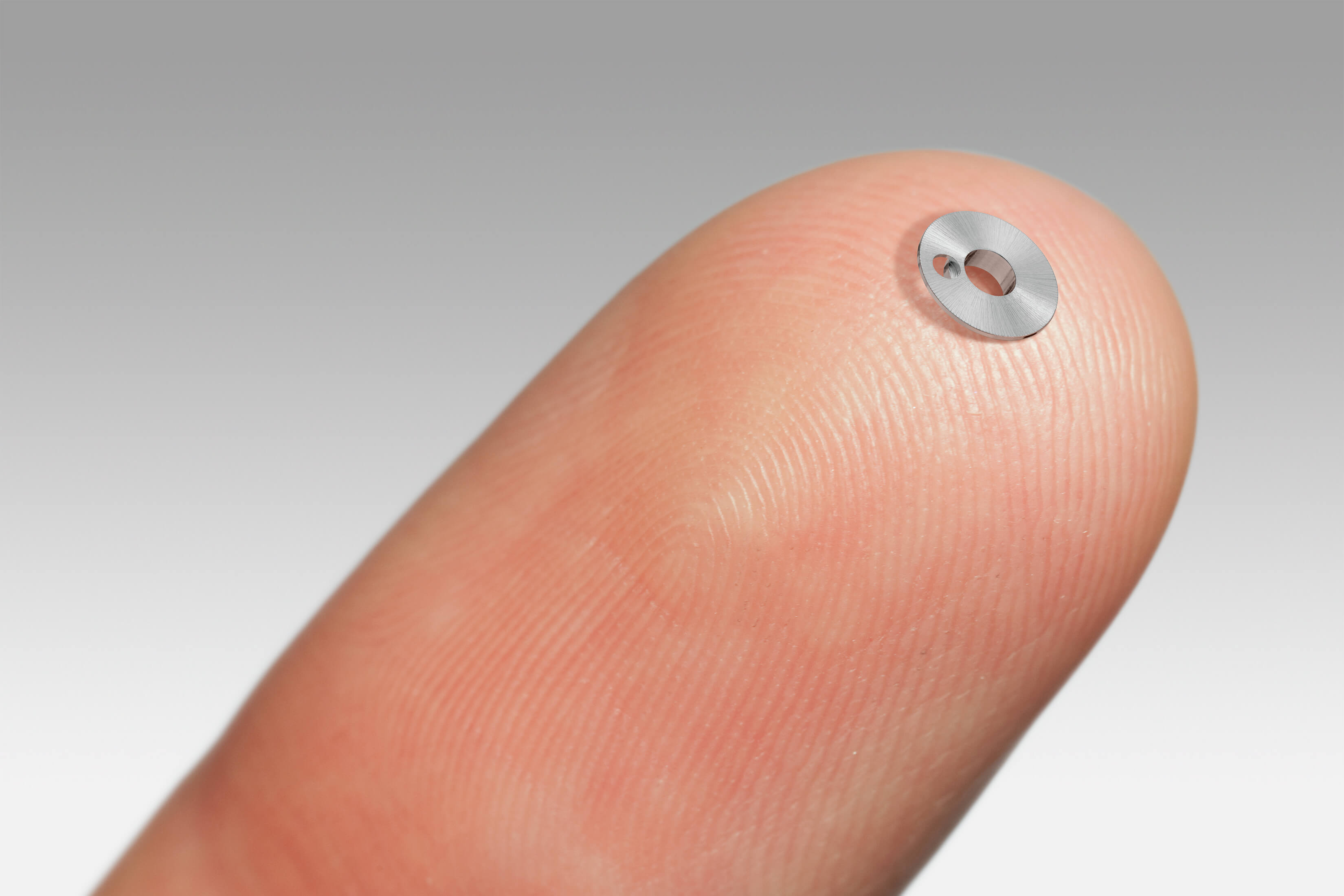

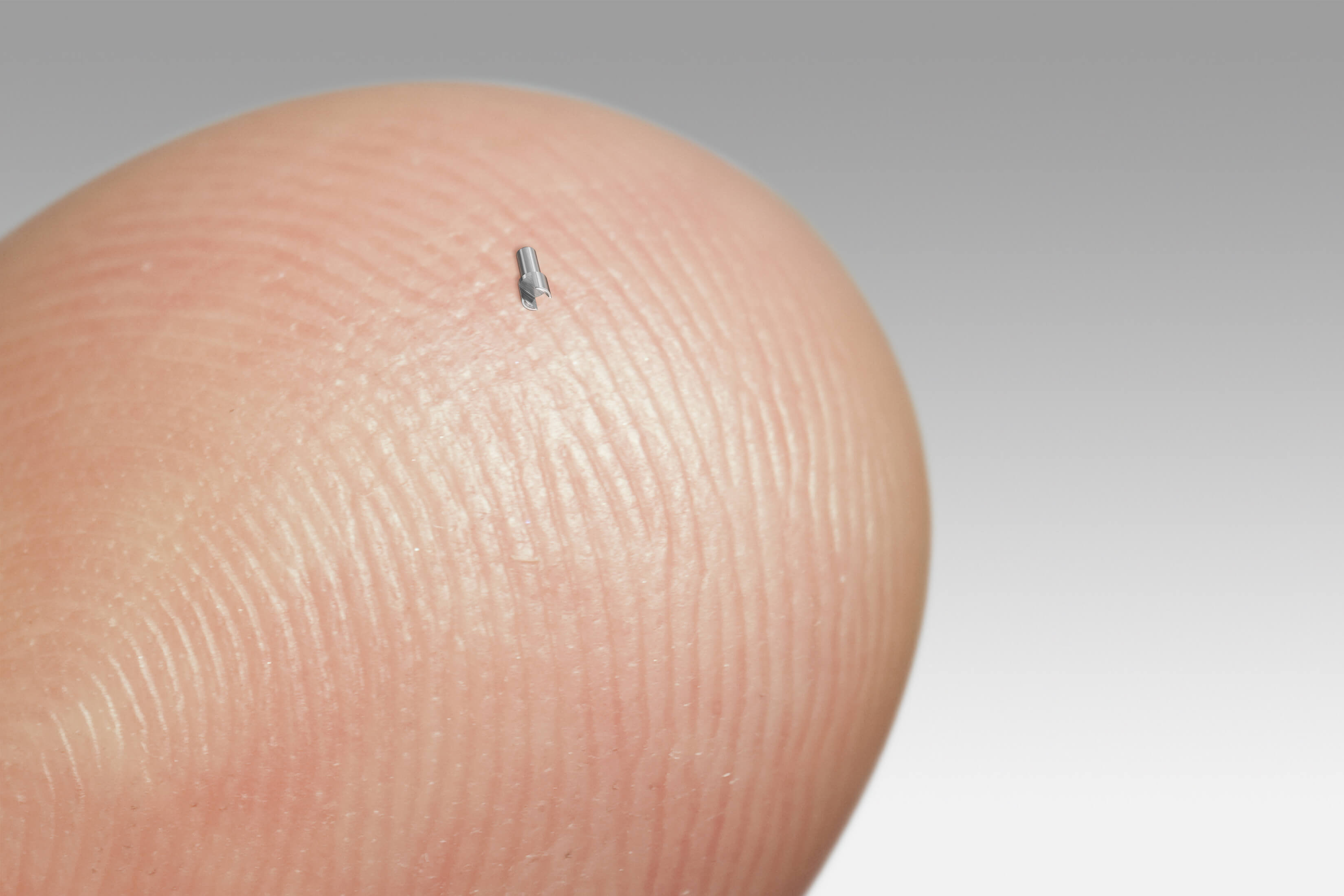

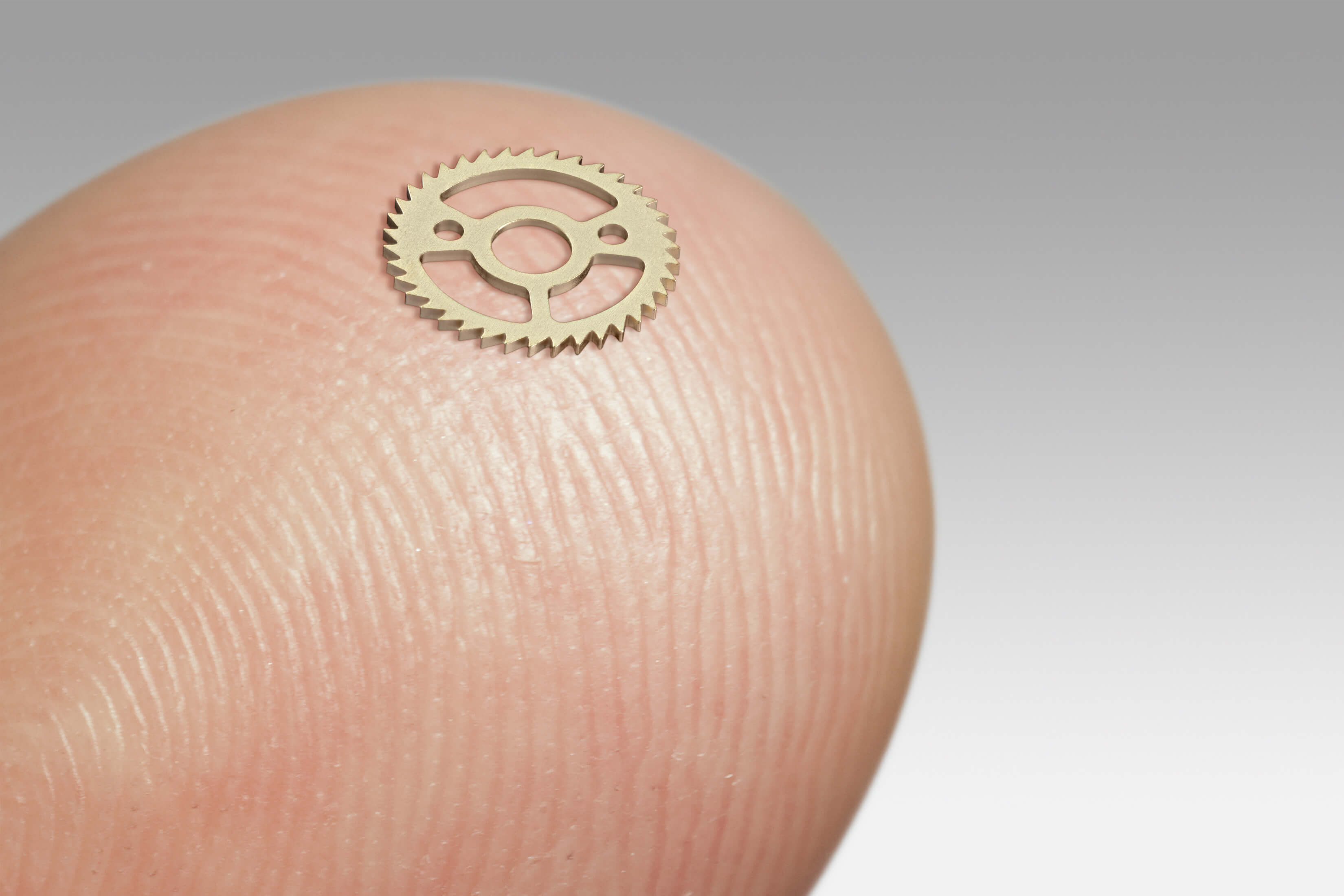

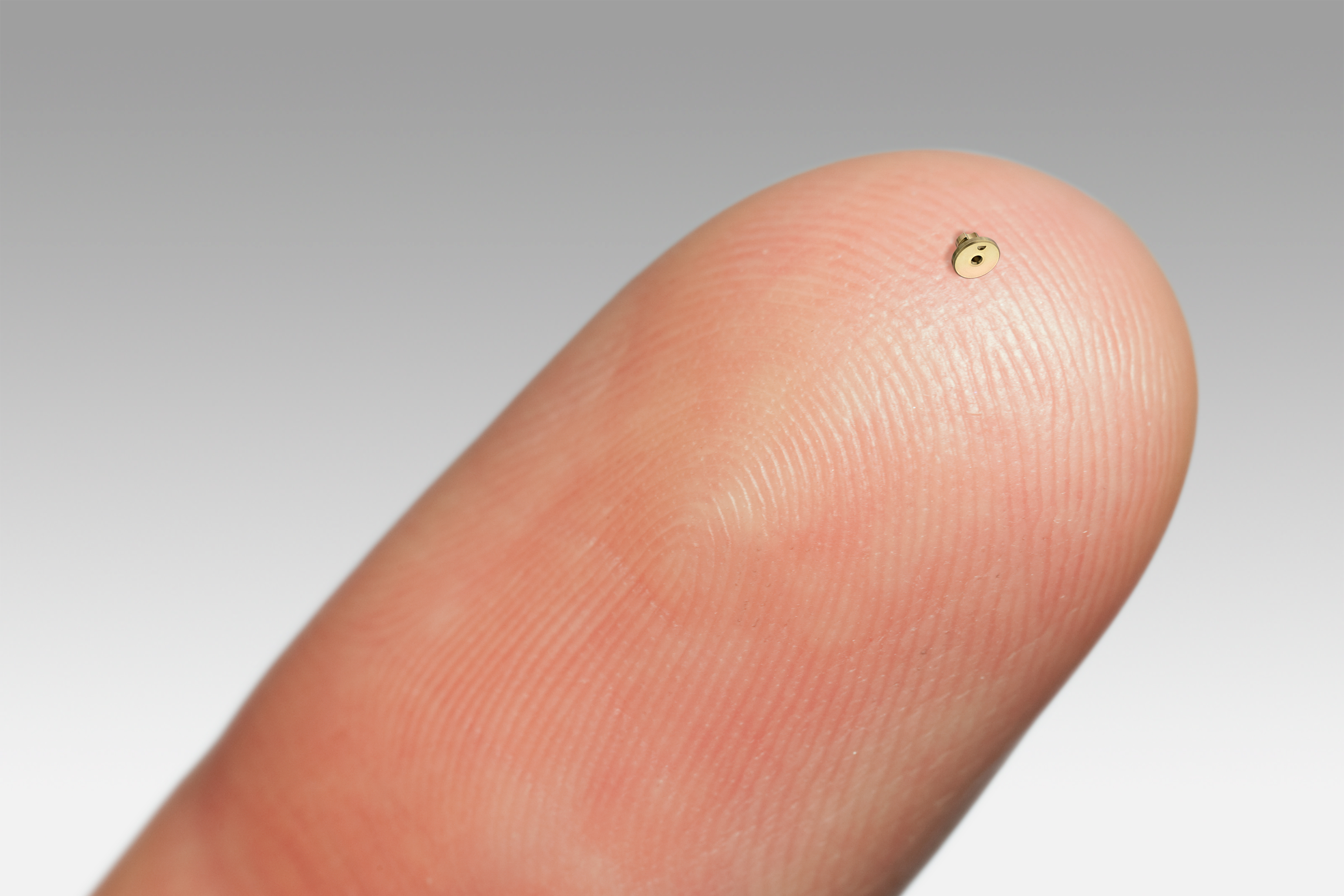

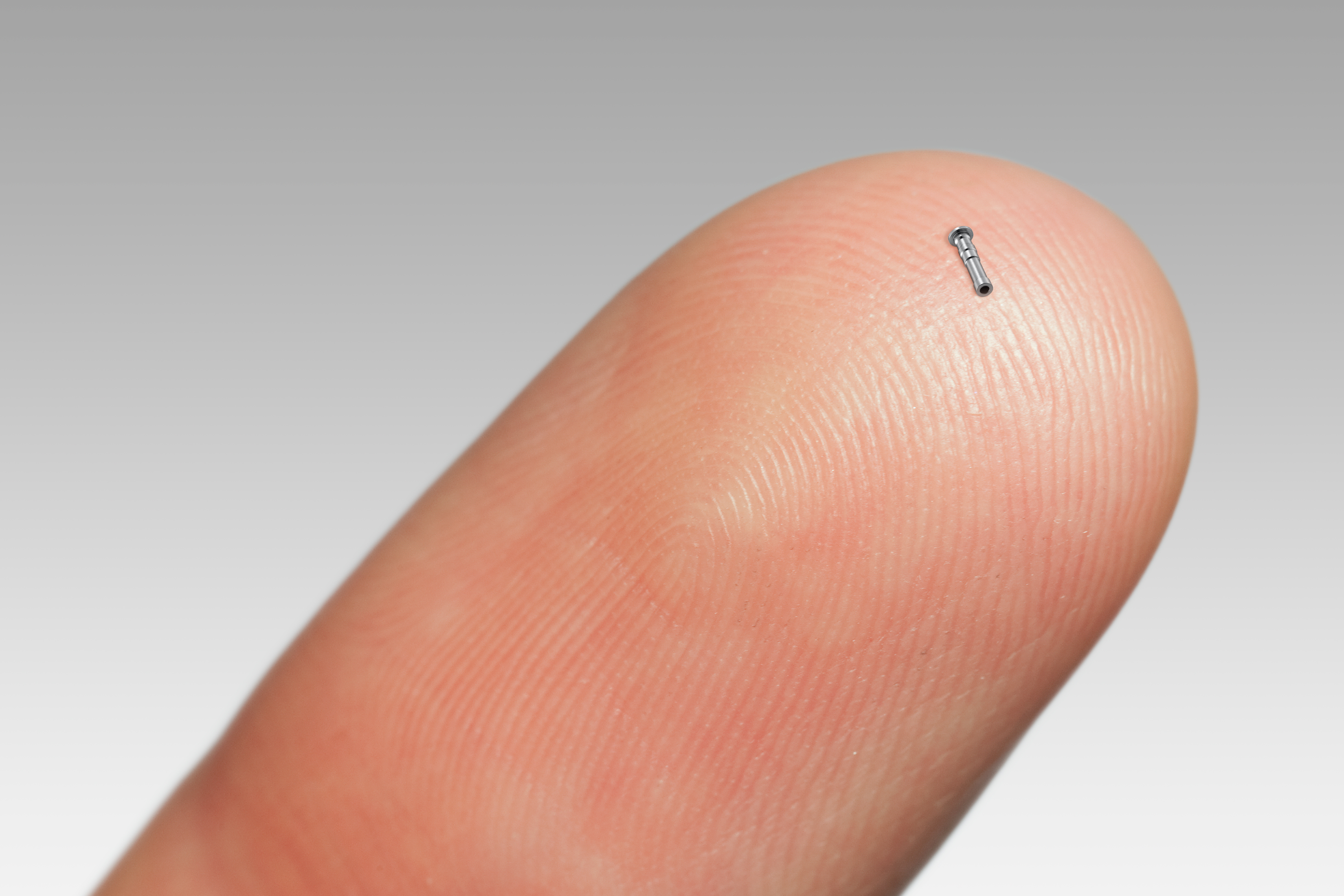

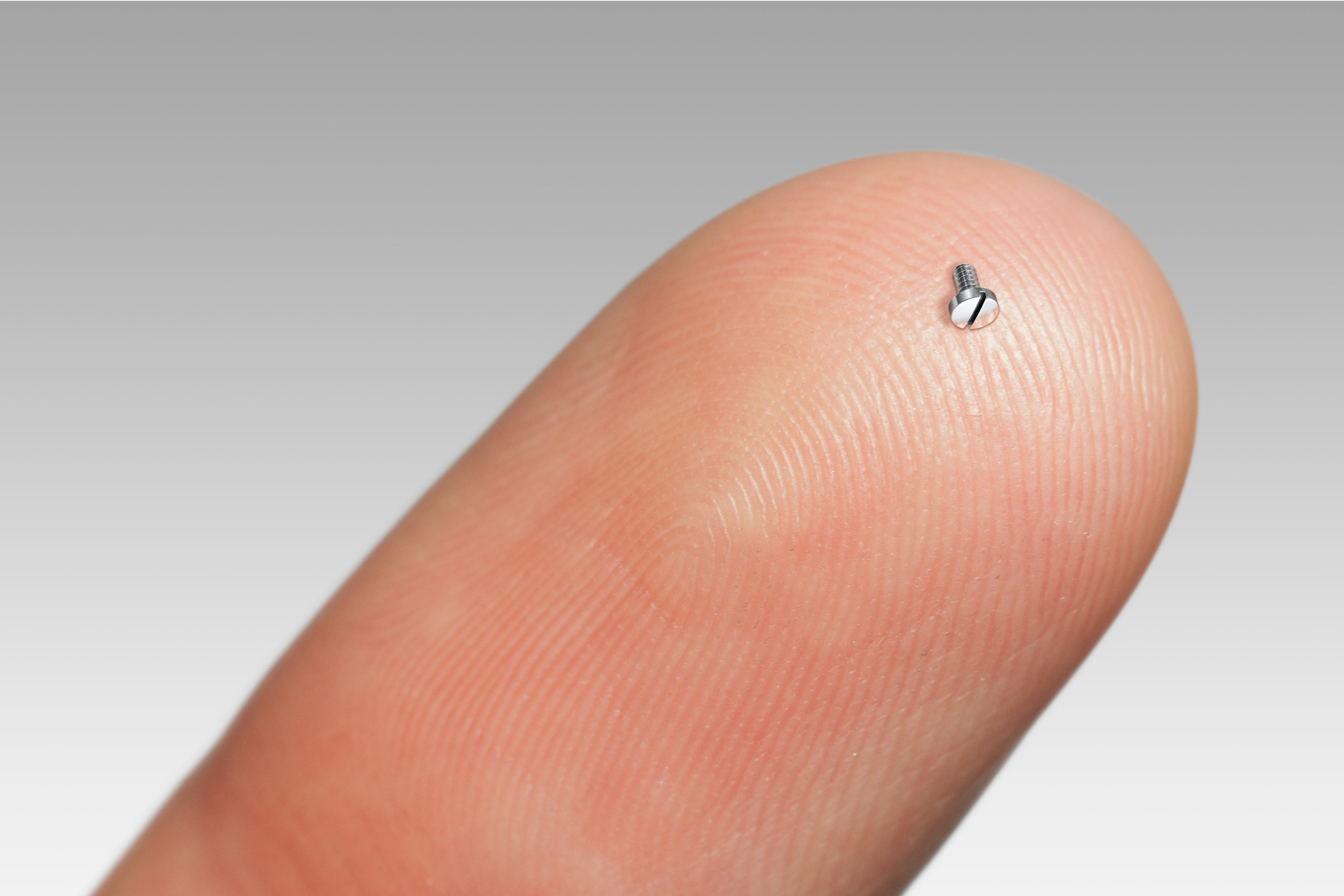

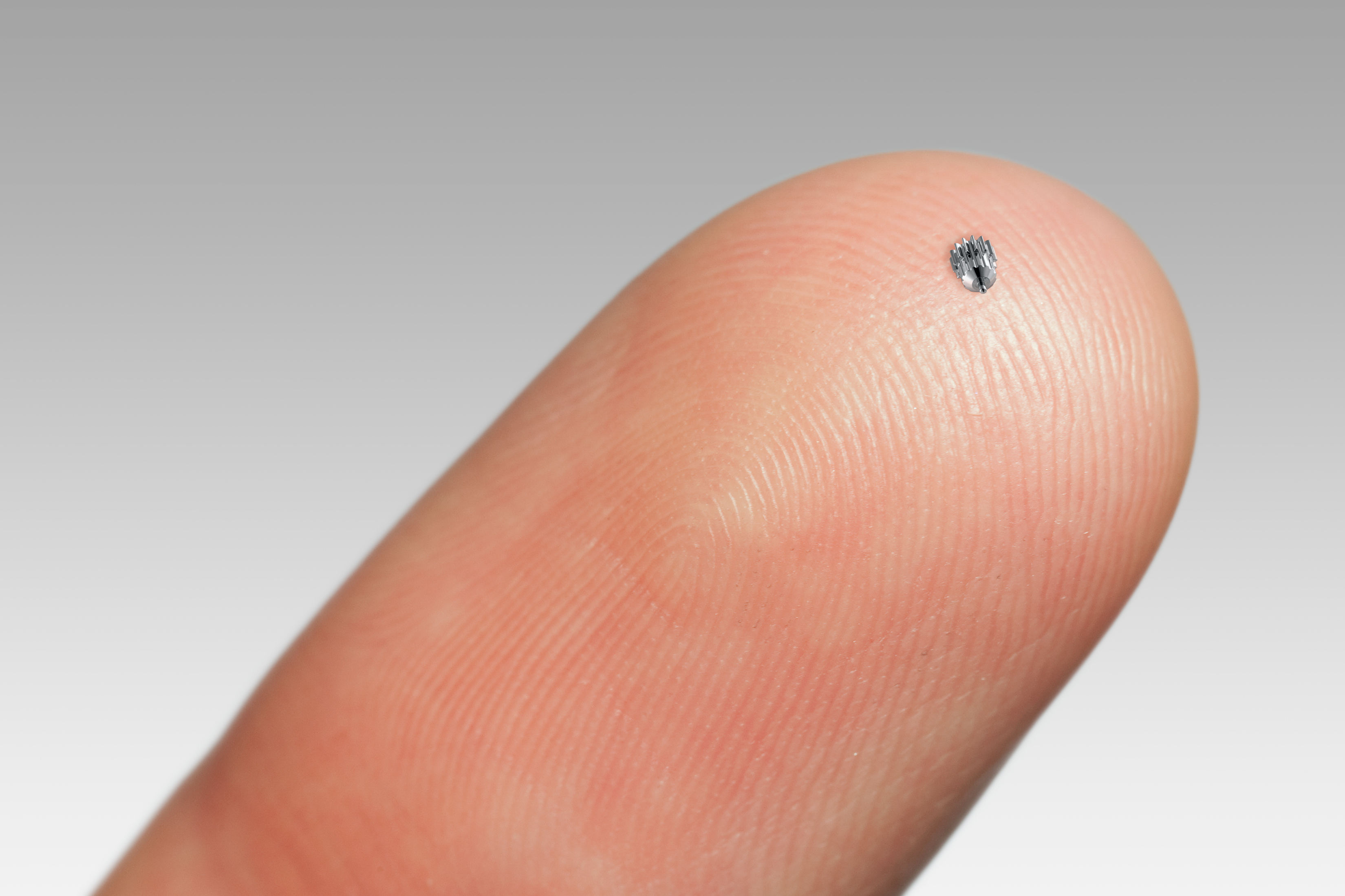

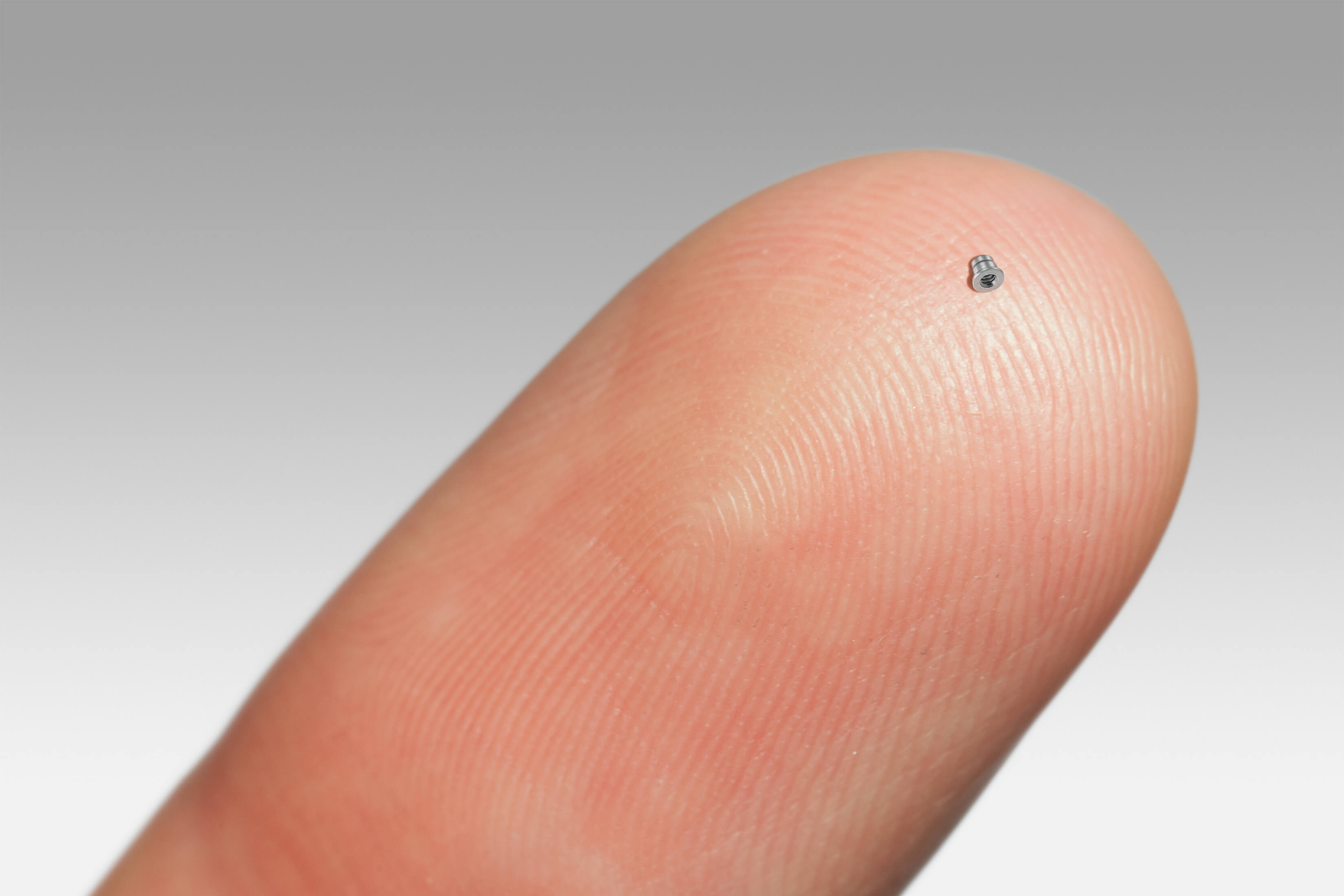

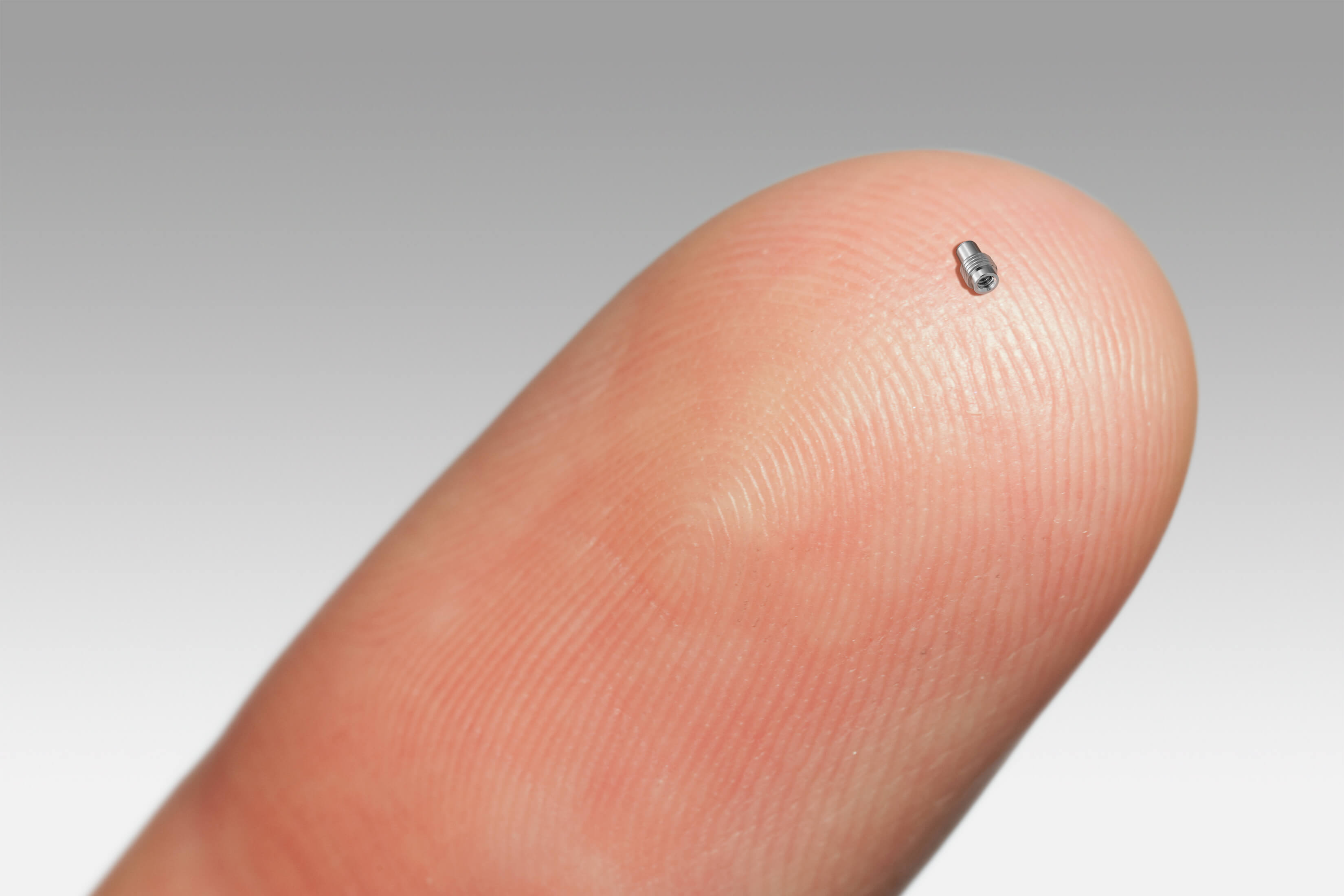

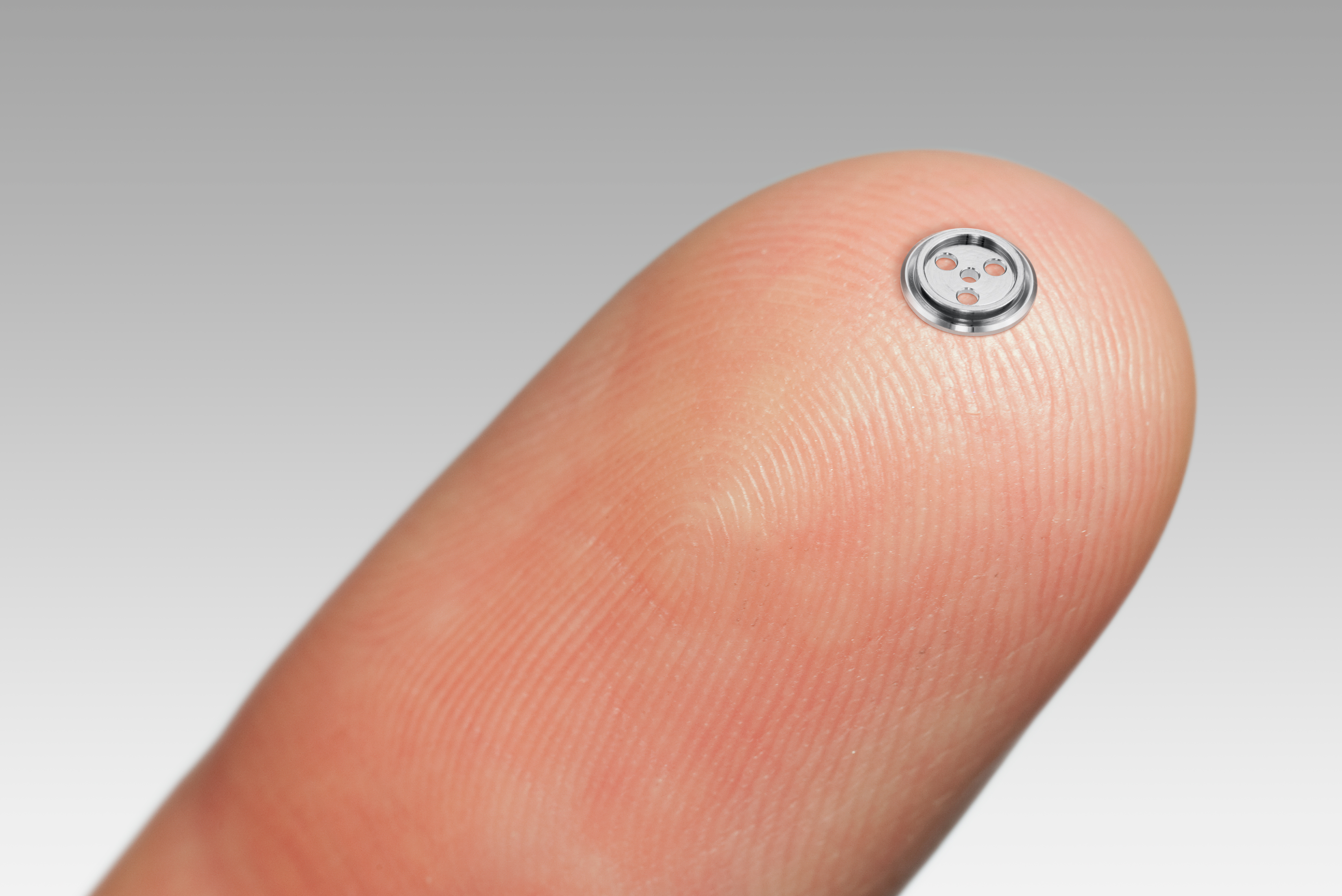

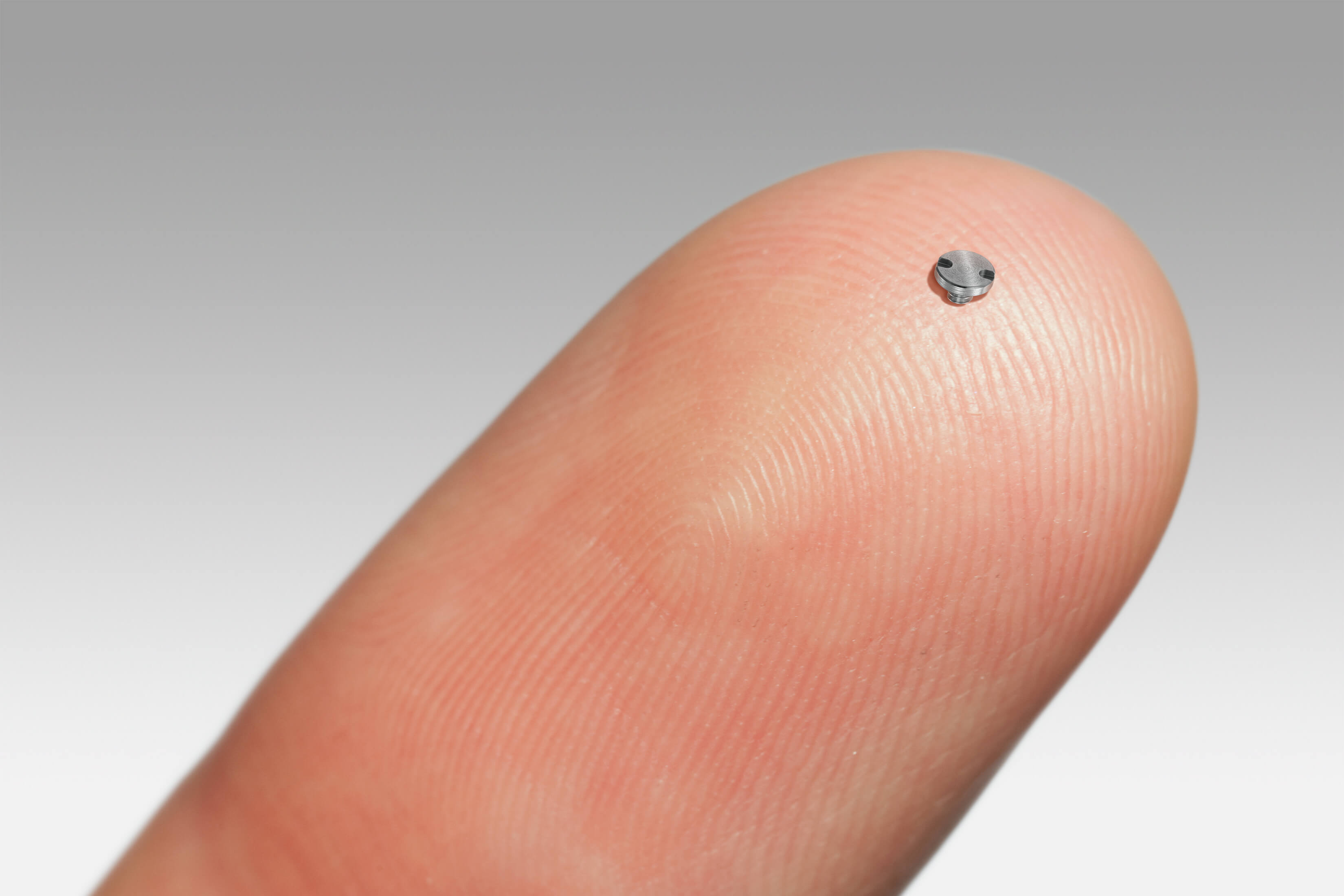

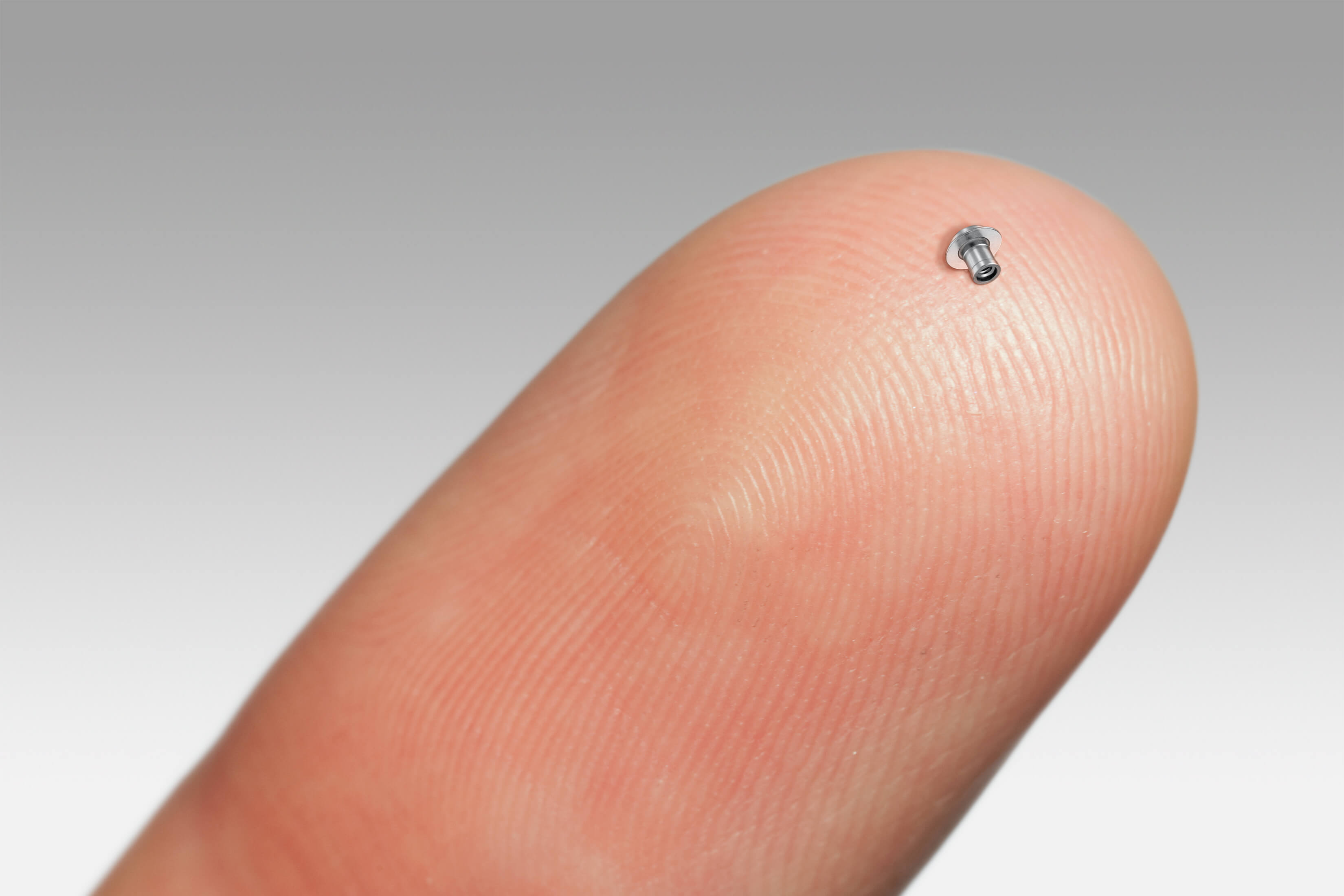

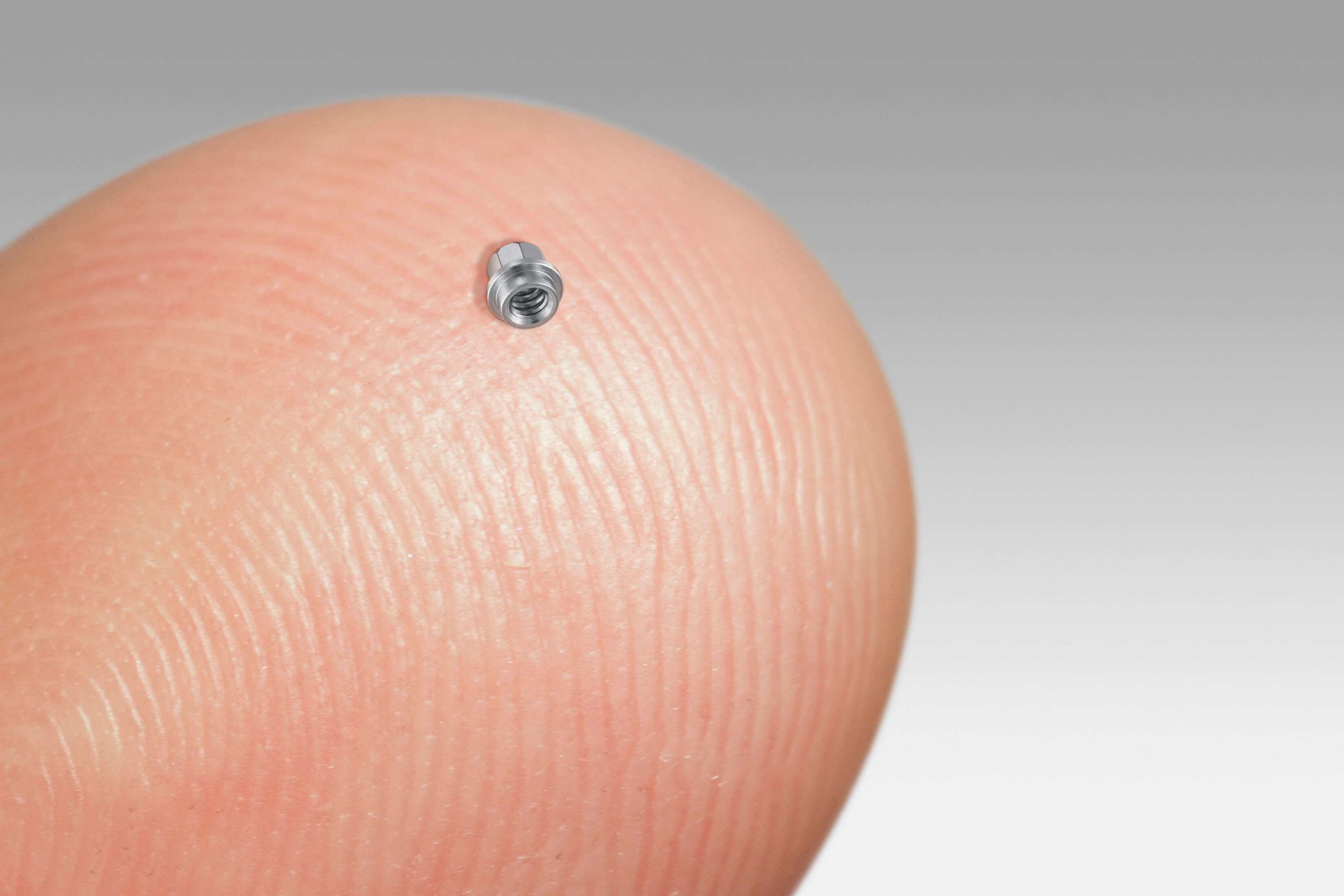

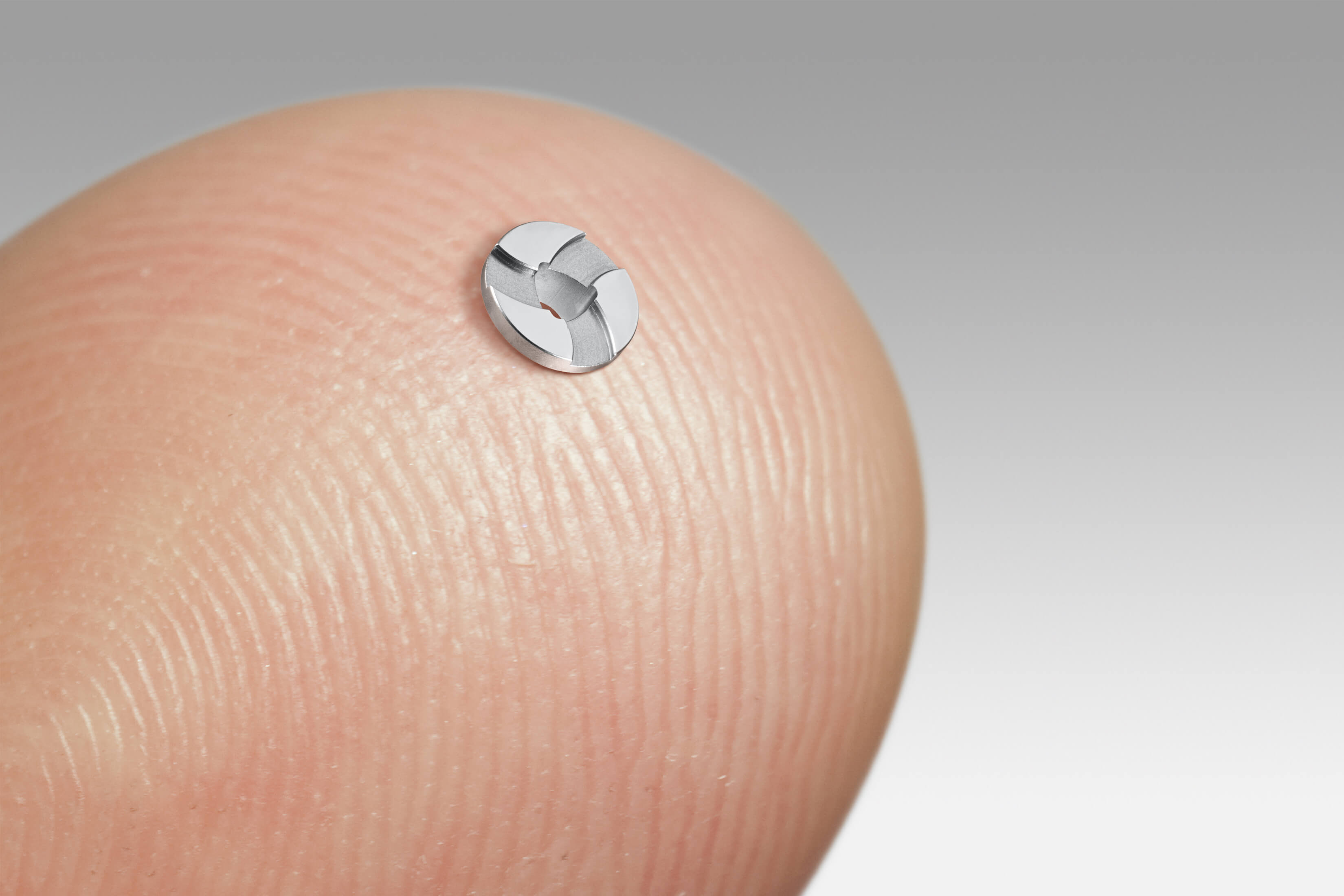

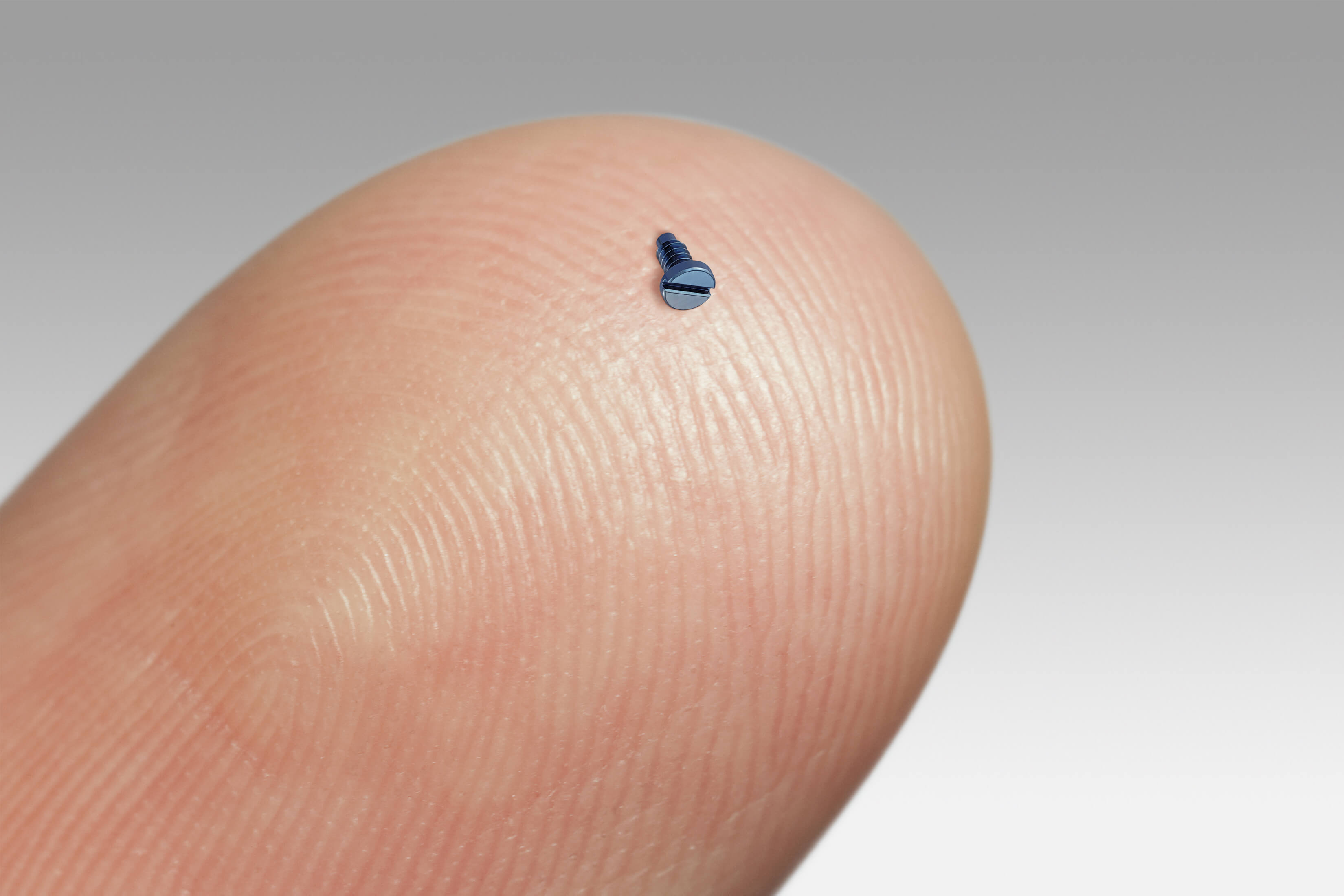

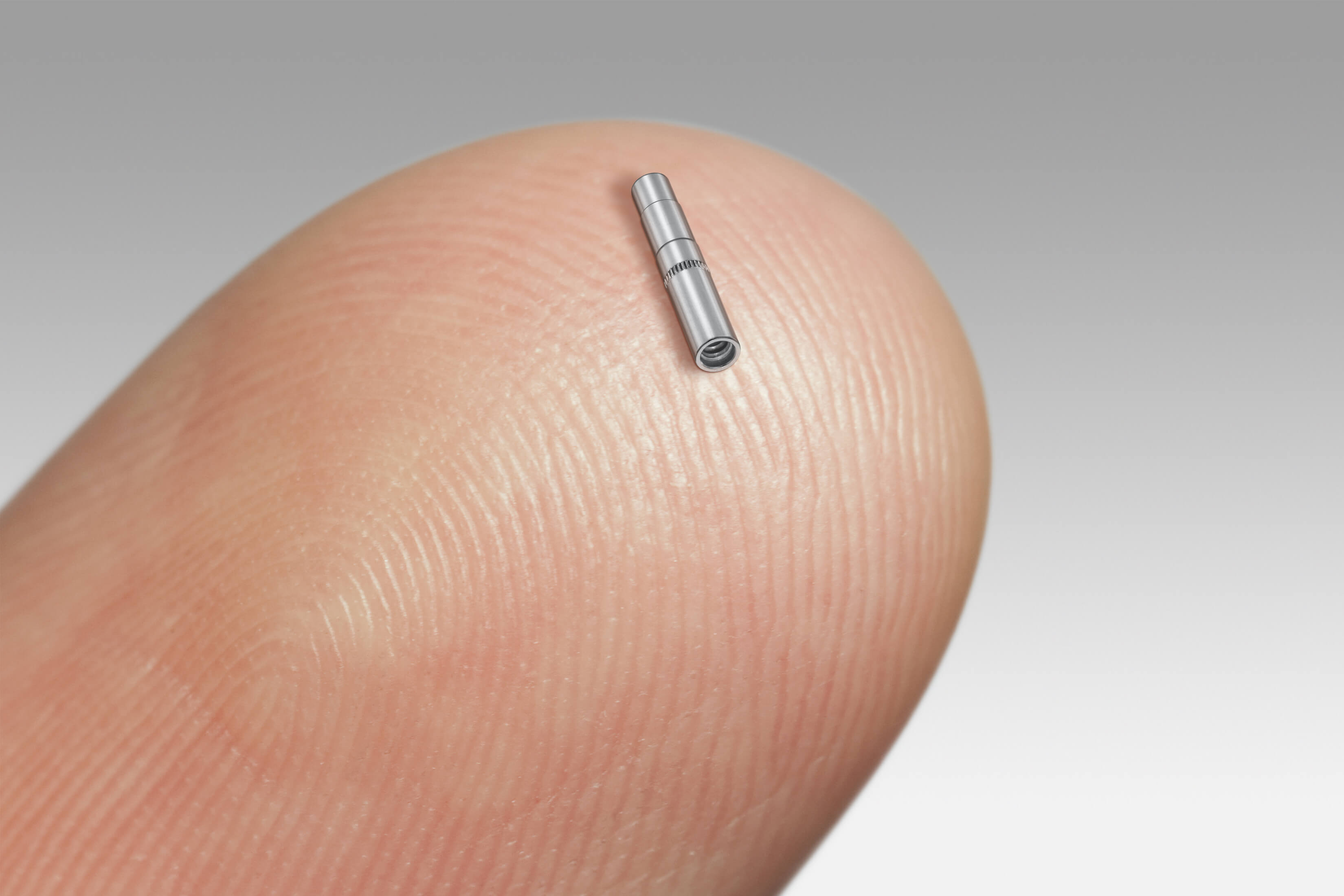

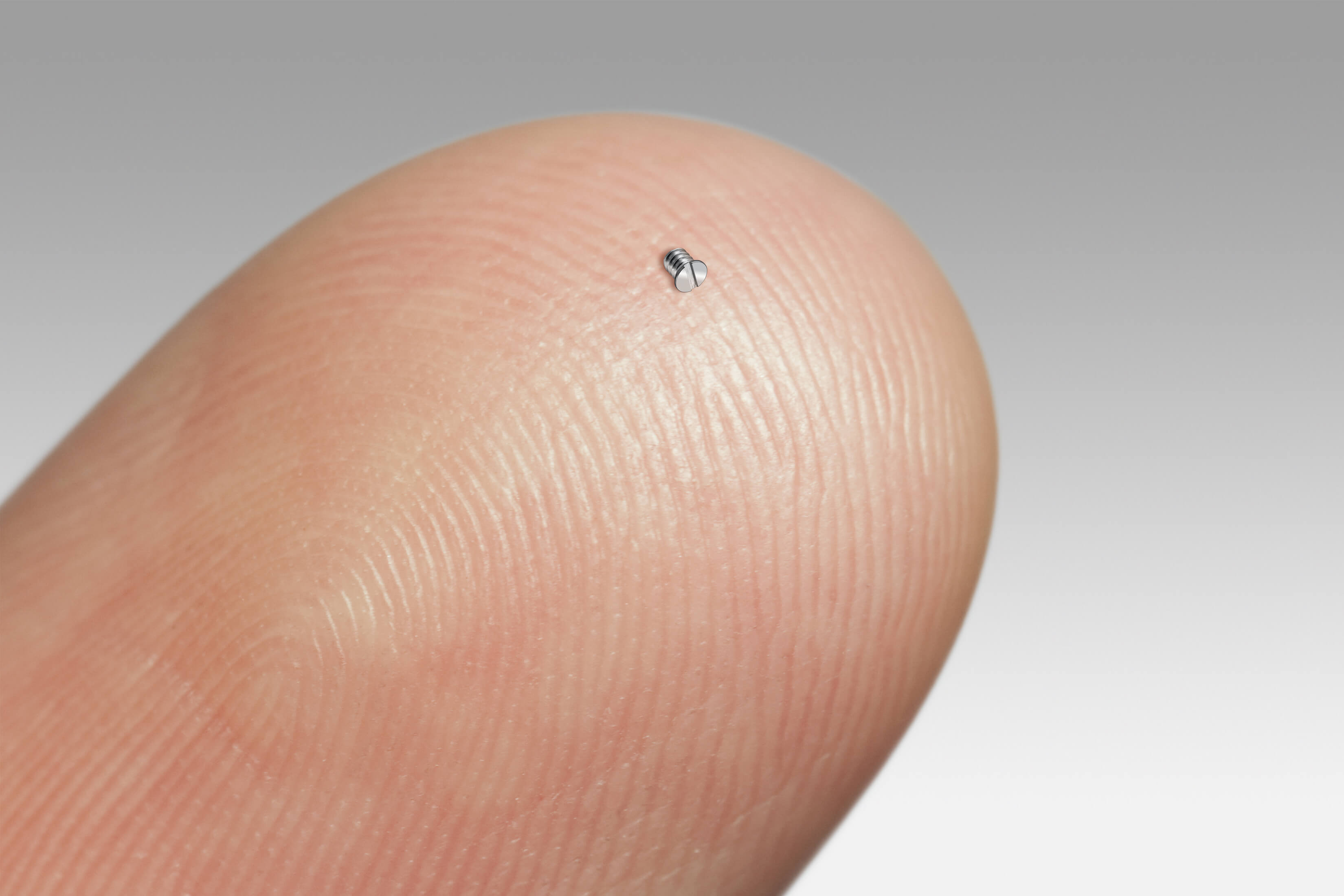

Specifications

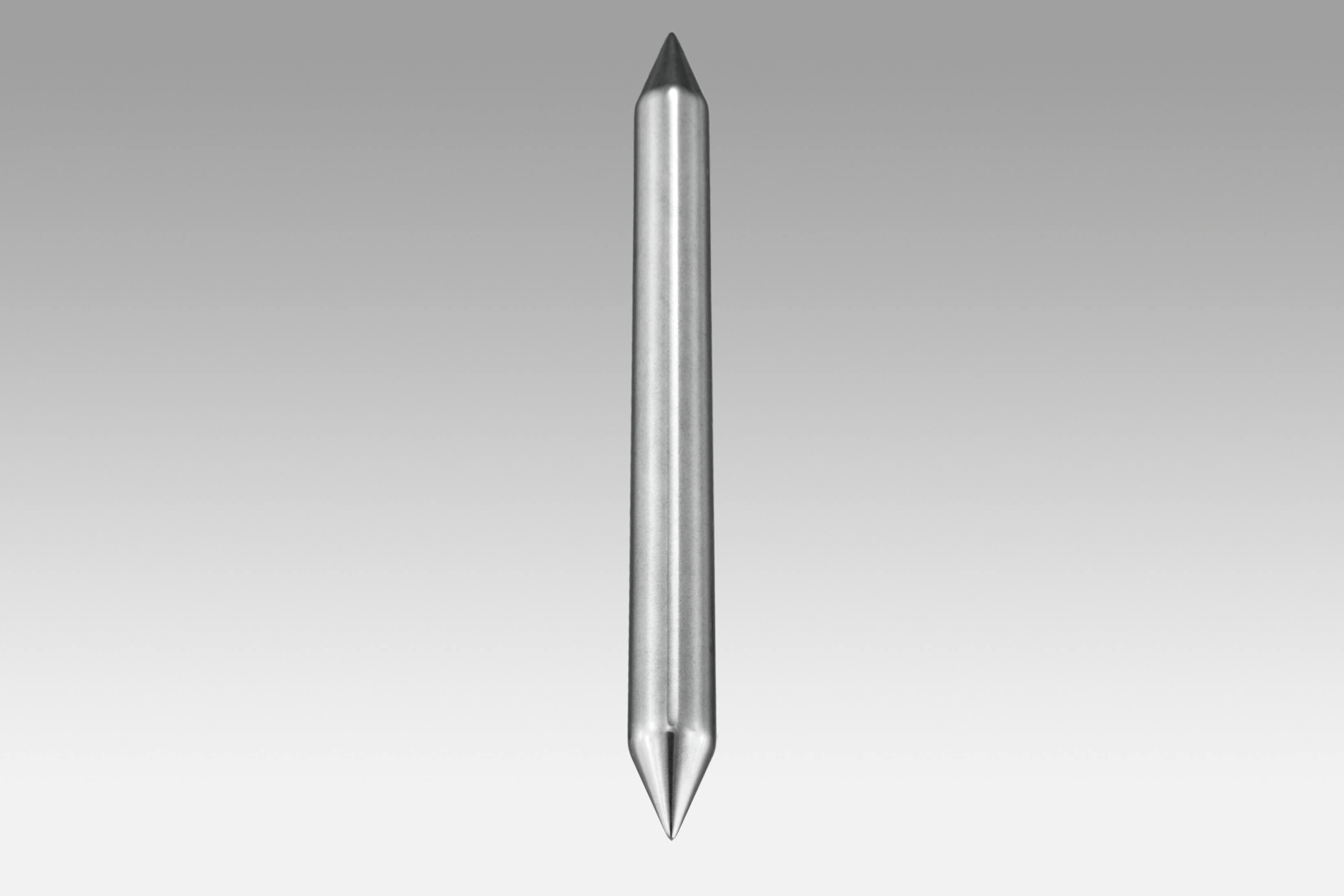

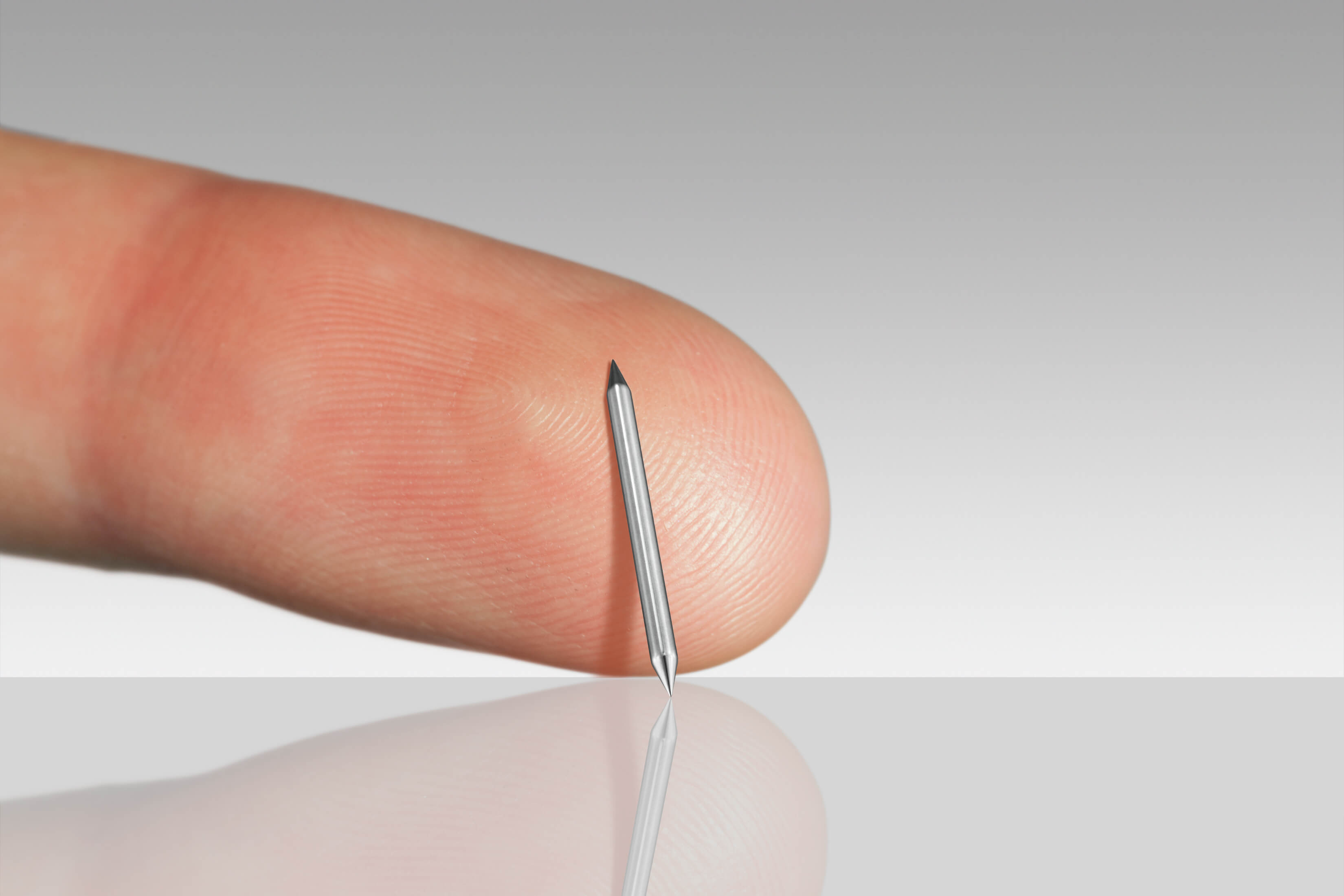

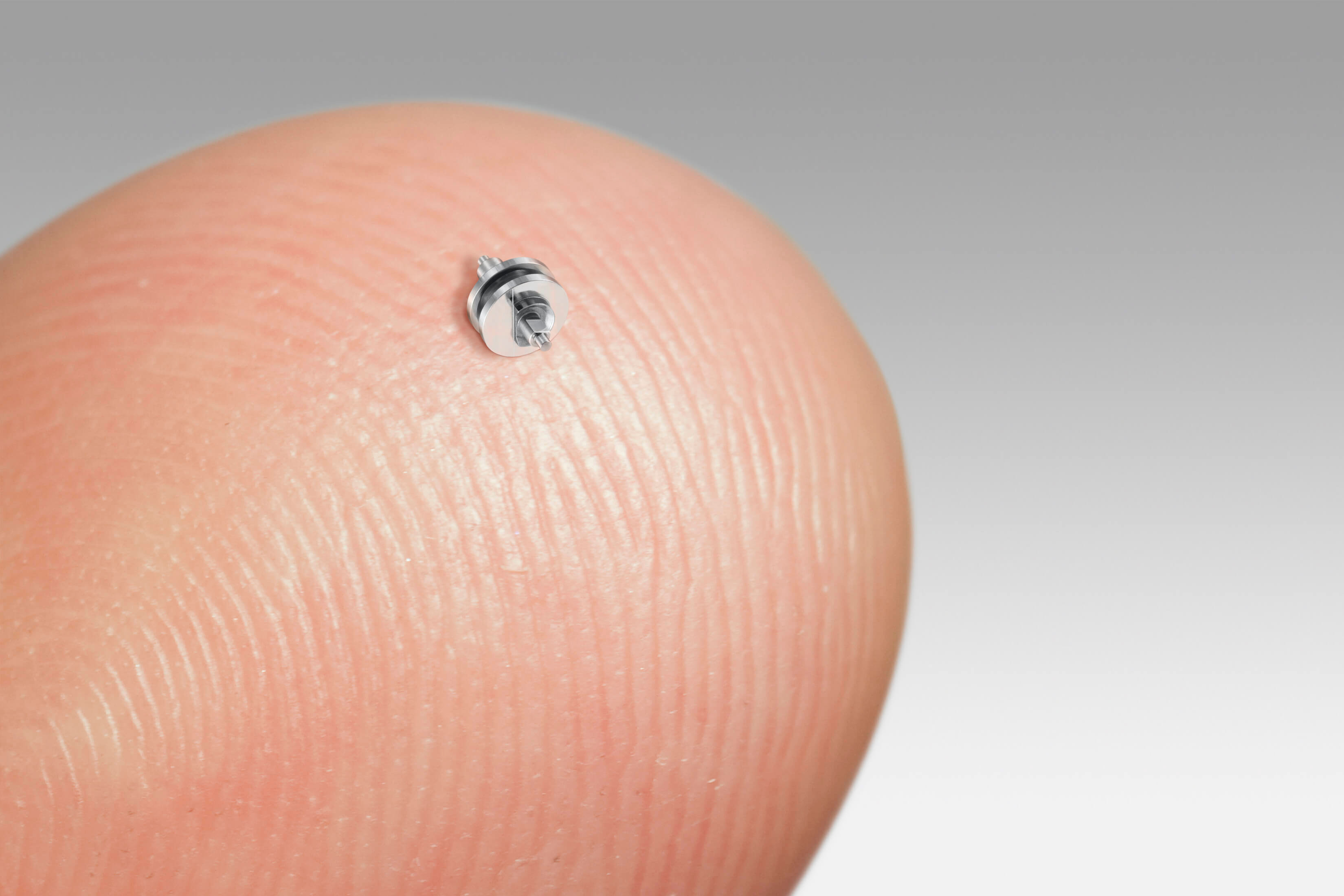

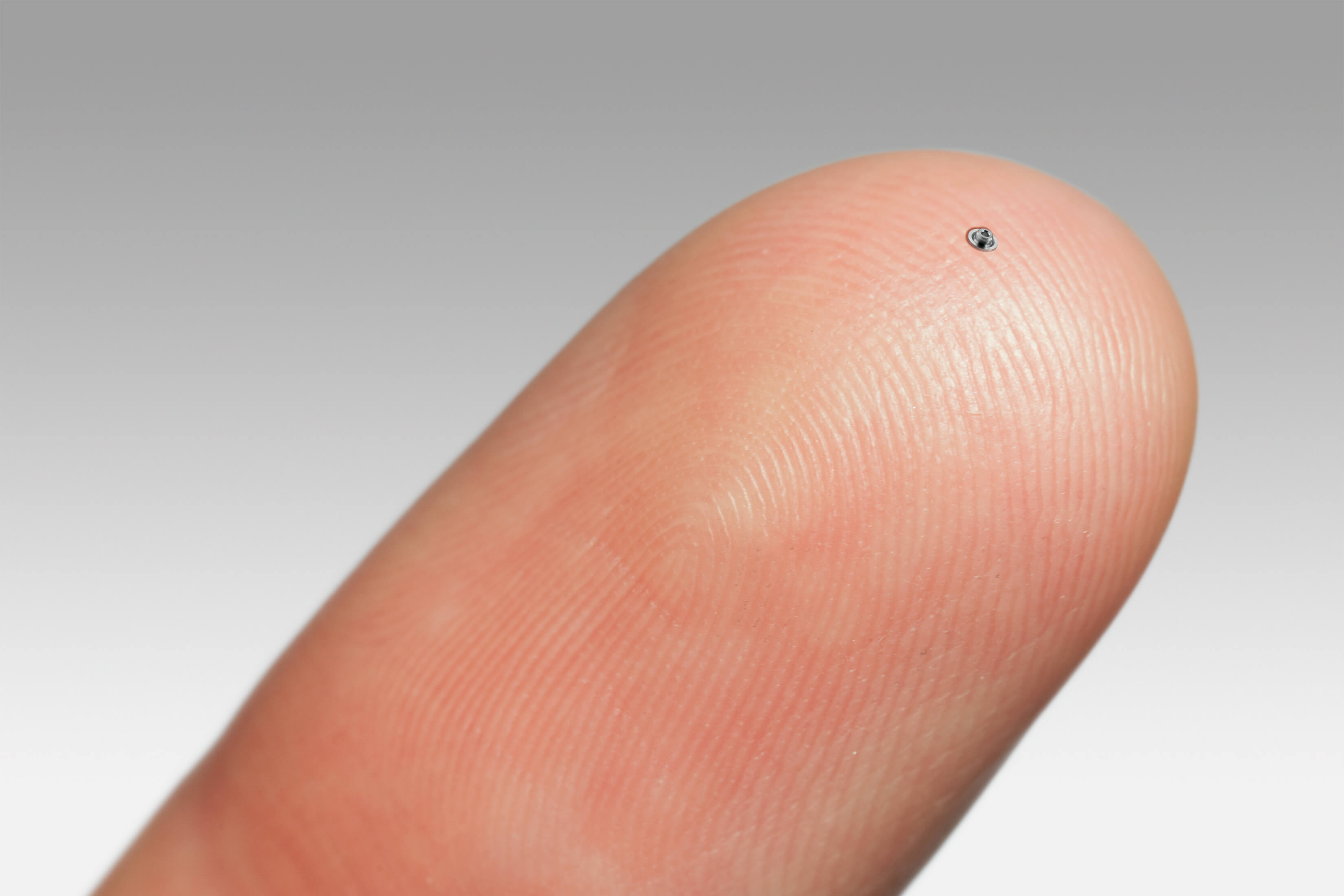

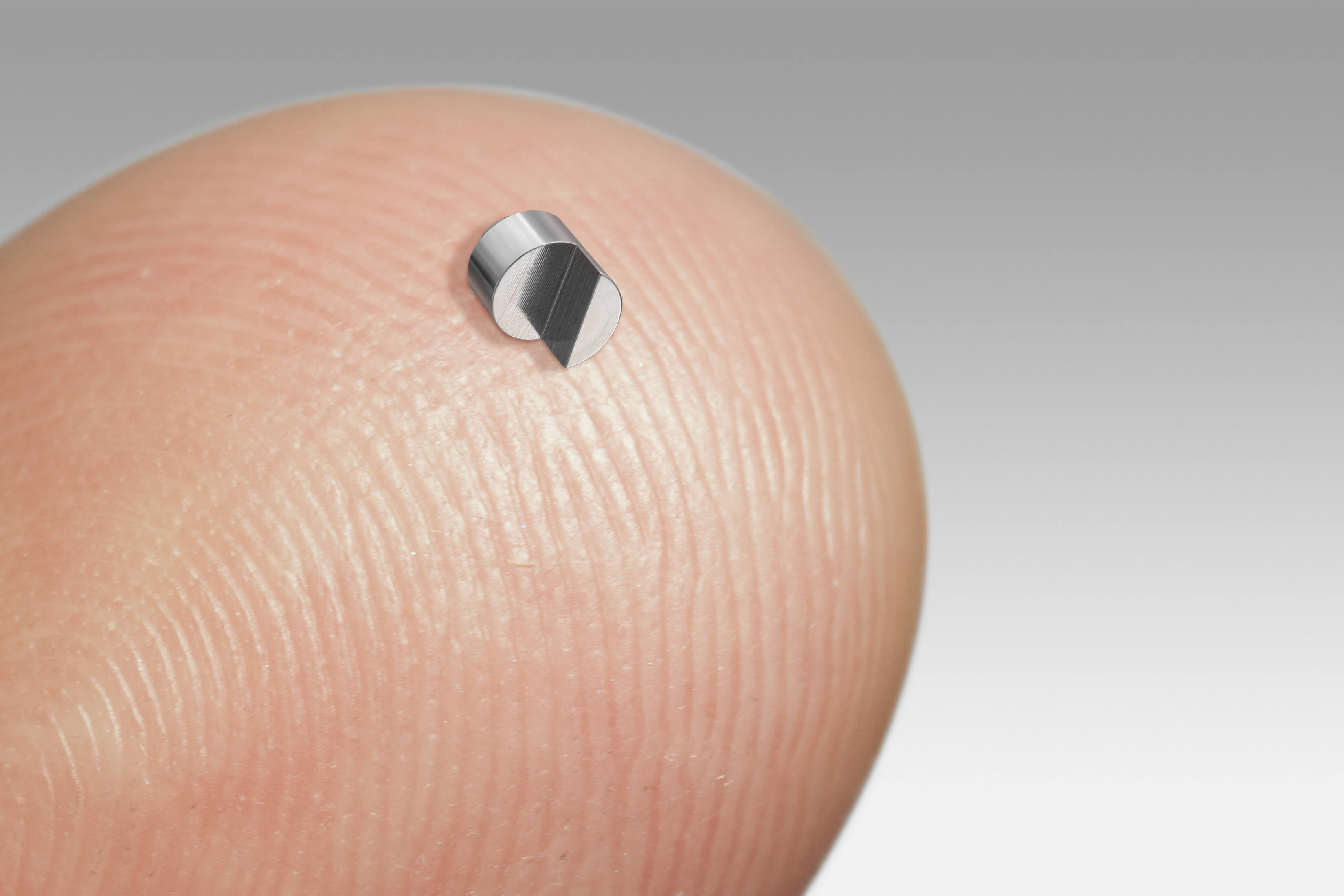

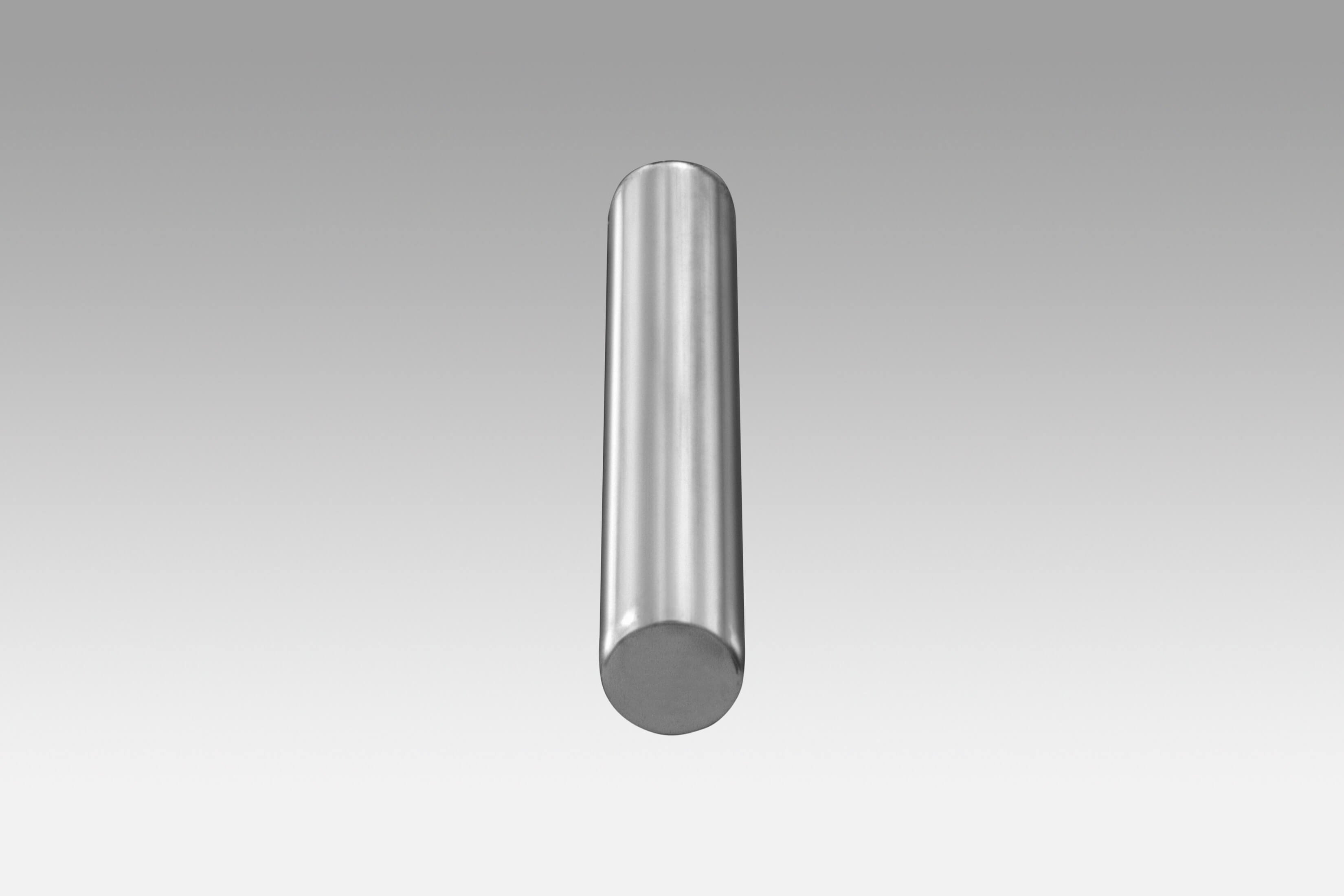

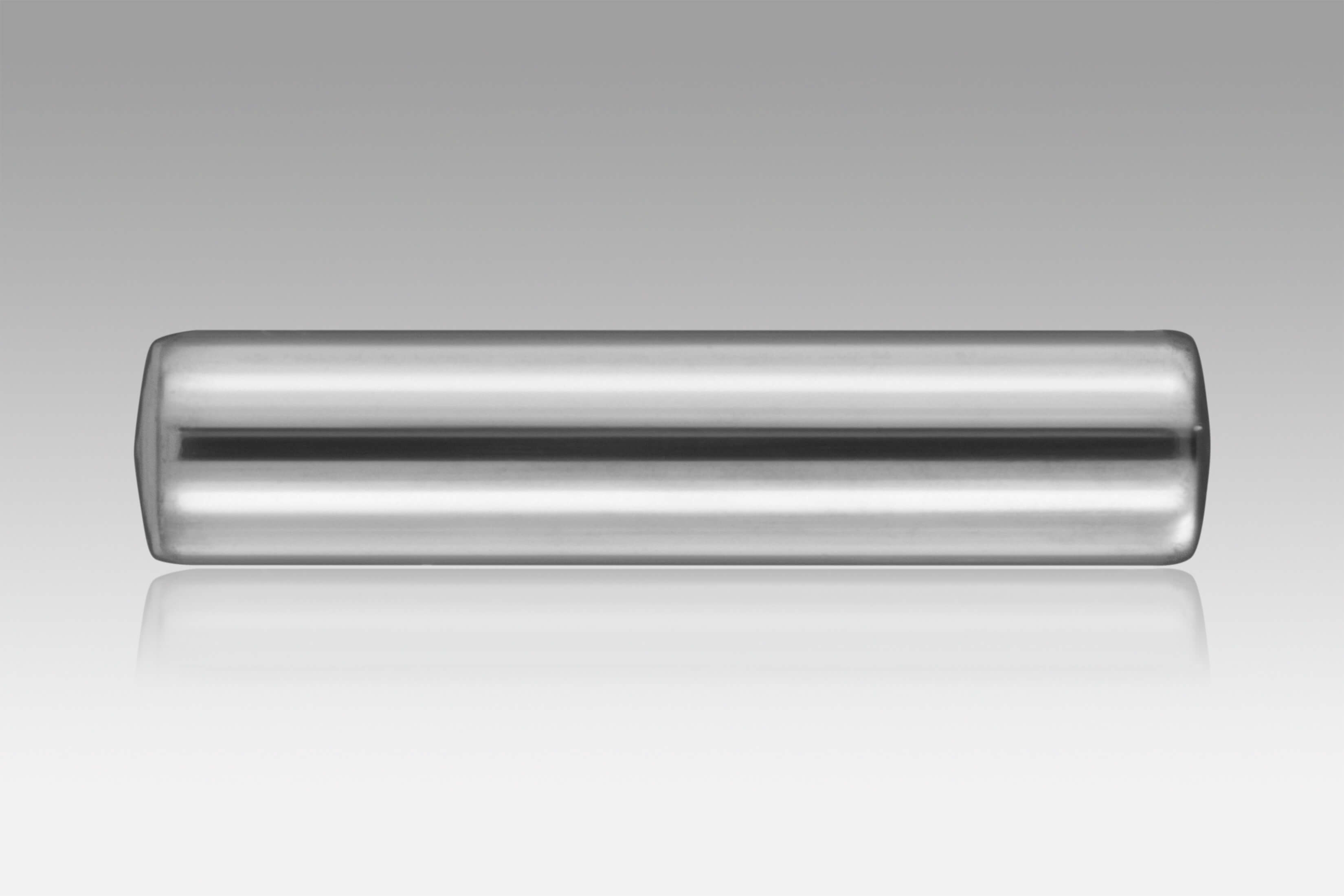

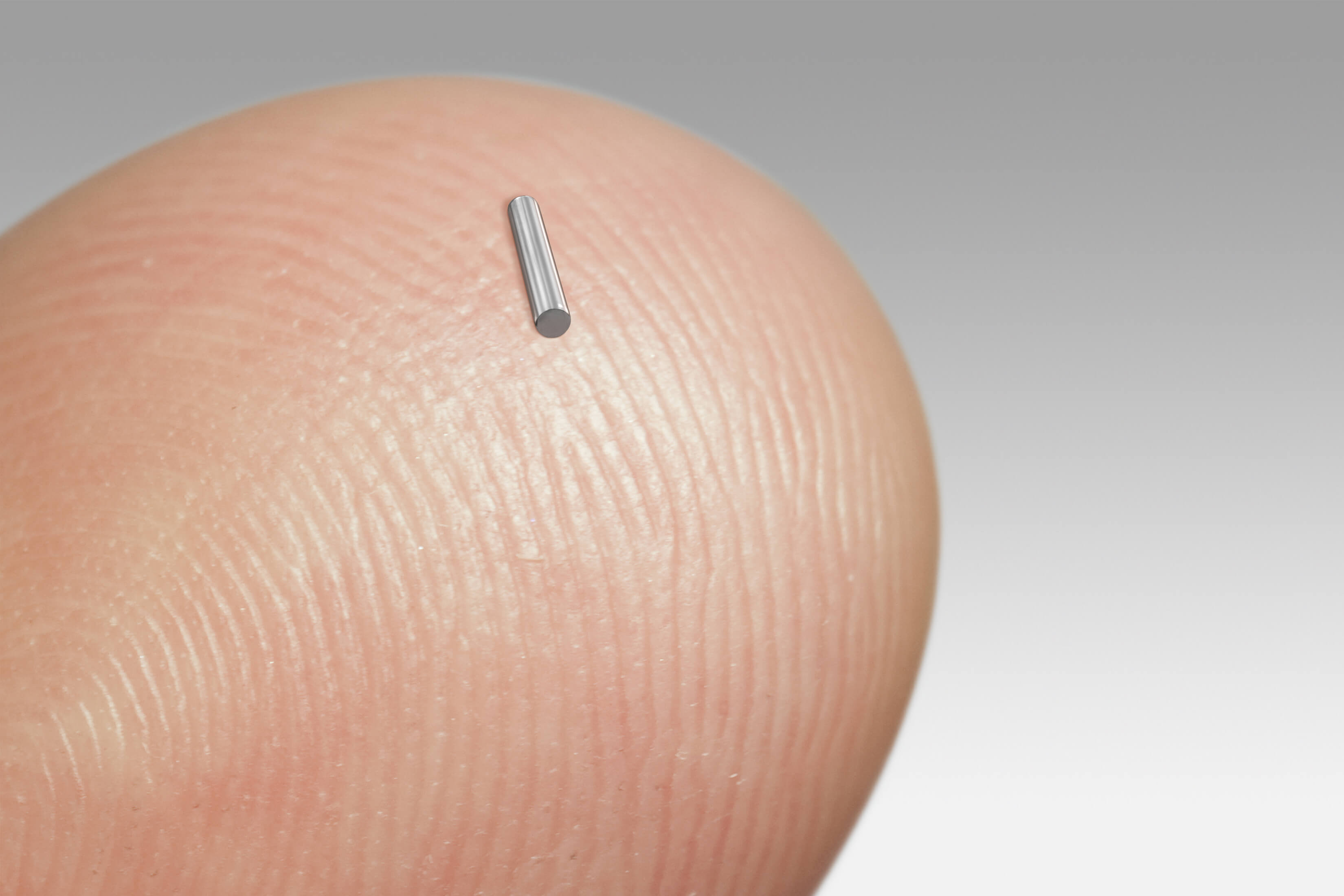

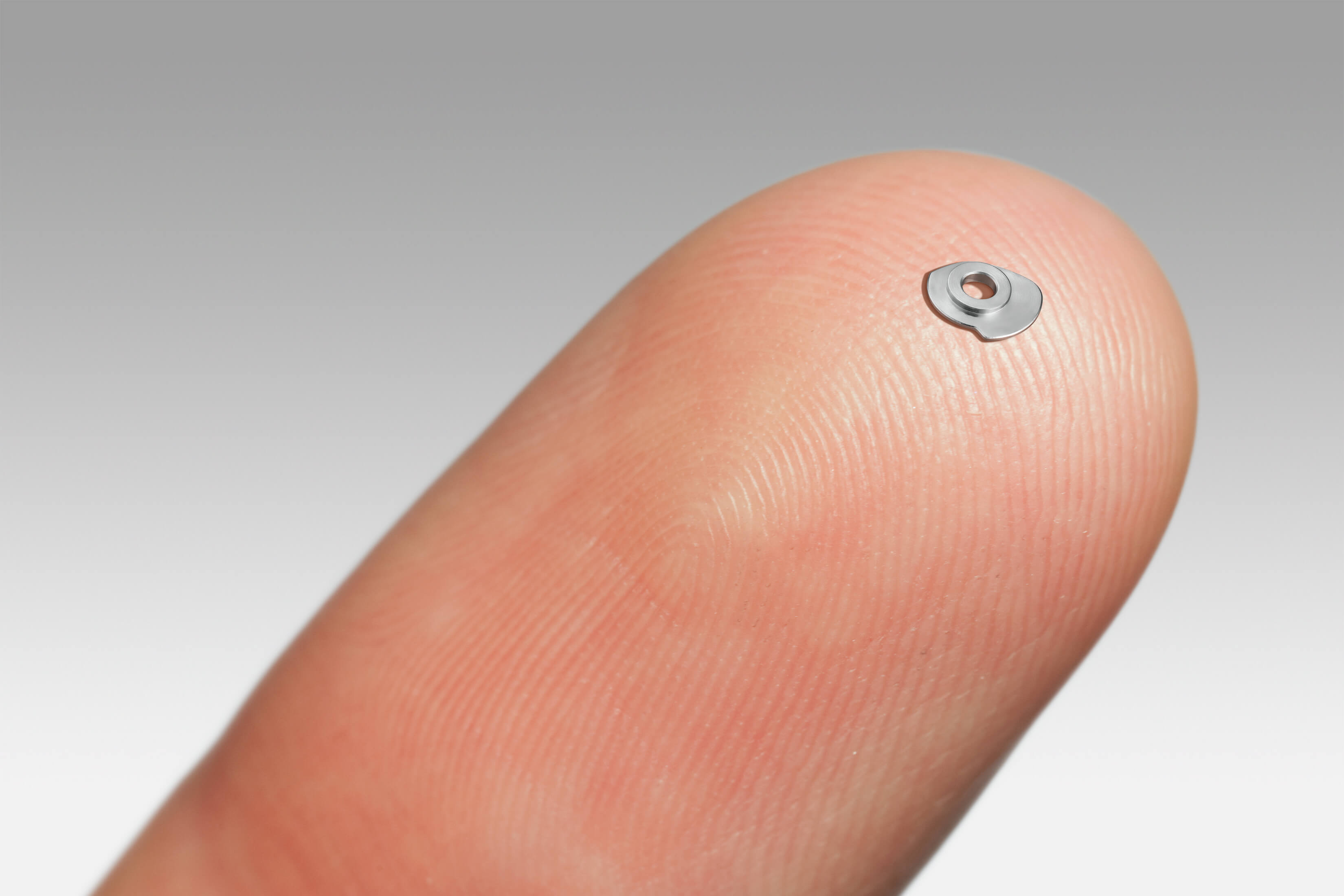

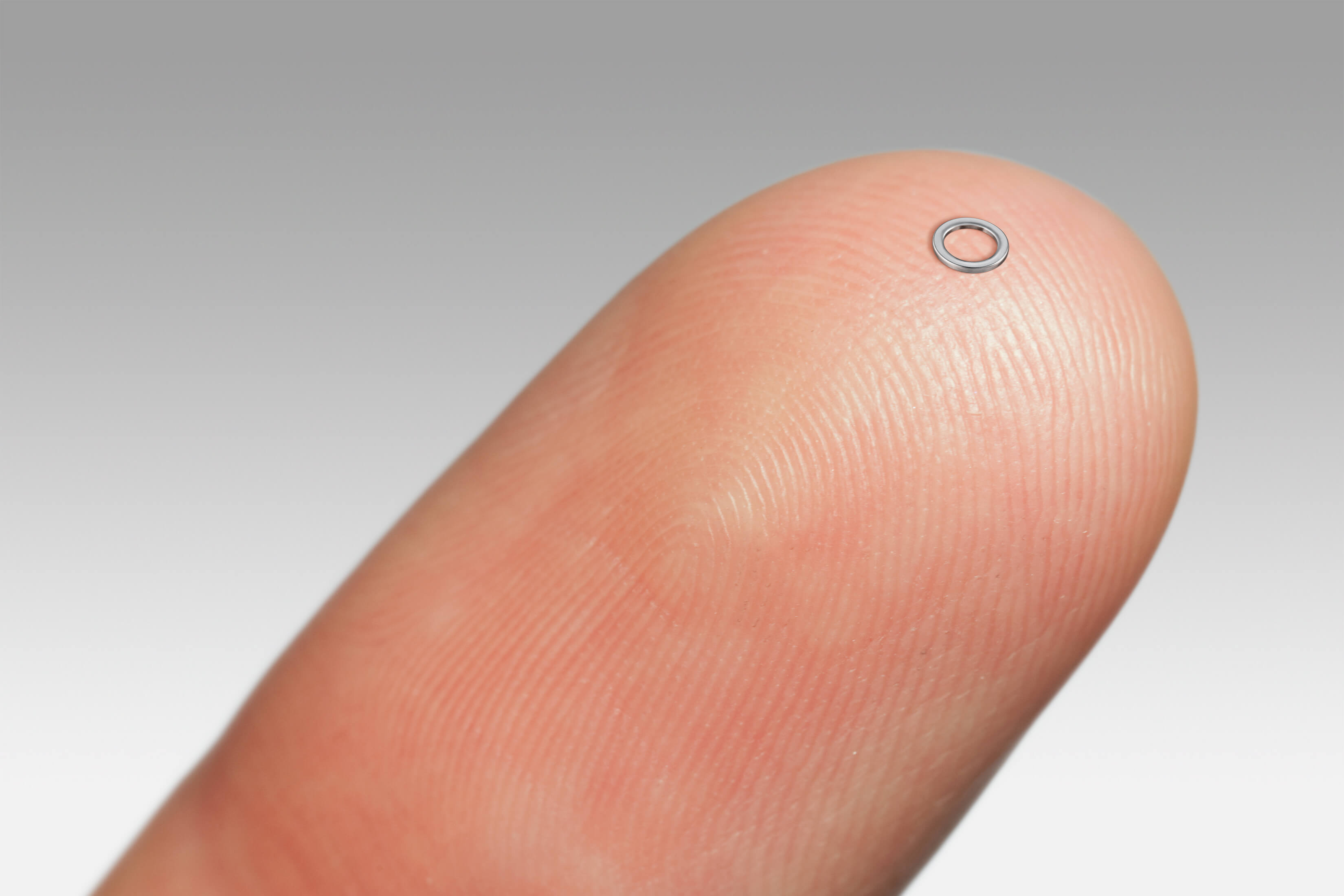

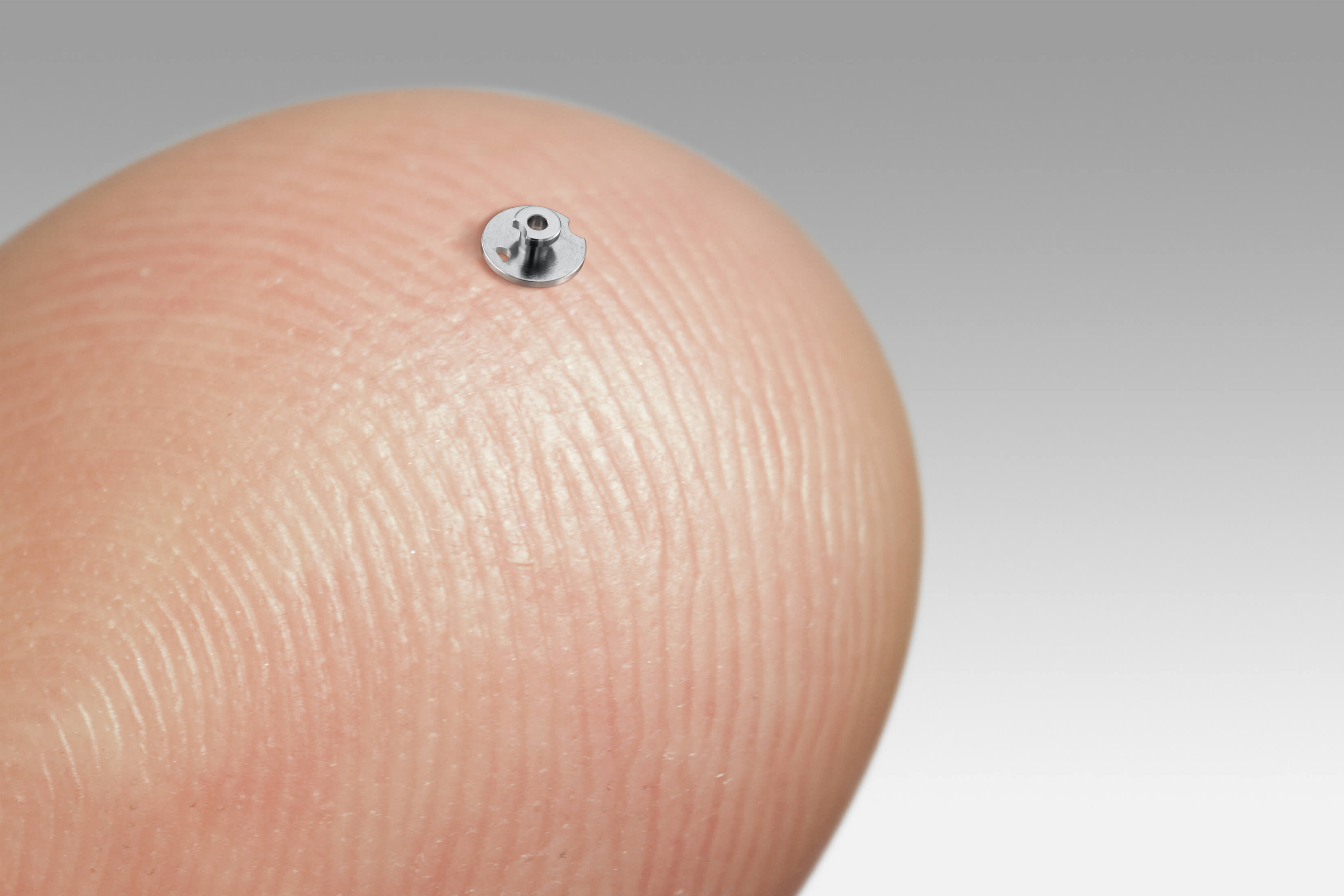

Usual dimensions

| Diameter 0.08-5.50 mm, Length 0.40-15.00 mm |

Usual tolerances

| Diameter ± 2µm (0.002 mm), Length ± 10µm (0.01 mm) |

Most commonly used materials

| 1.4197/Chronifer Labor M-Plus, 1.4305/18/8 stainless steel, 1.4441/316 LS stainless steel, brass, CuBe, Declafor, Ecobrass, gold, LAW 100 Pb steel, nickel silver, palladium alloy, Sandvik 20AP, Sandvik 4C27A, Sandvik Finemac, etc.

|

Common operations and treatments

| Black polishing/mirror polishing, bluing, chemical polishing, domed polishing, gold plating, hardening, micro-polishing, nickel plating, polishing, rhodium plating, sand-blasting/micro-blasting, structural hardening, sunray polishing, tempering, etc.

|

| Certifications | ISO 9001, ISO 14001, ISO 45001, IATF 16949, ISO 13485 |

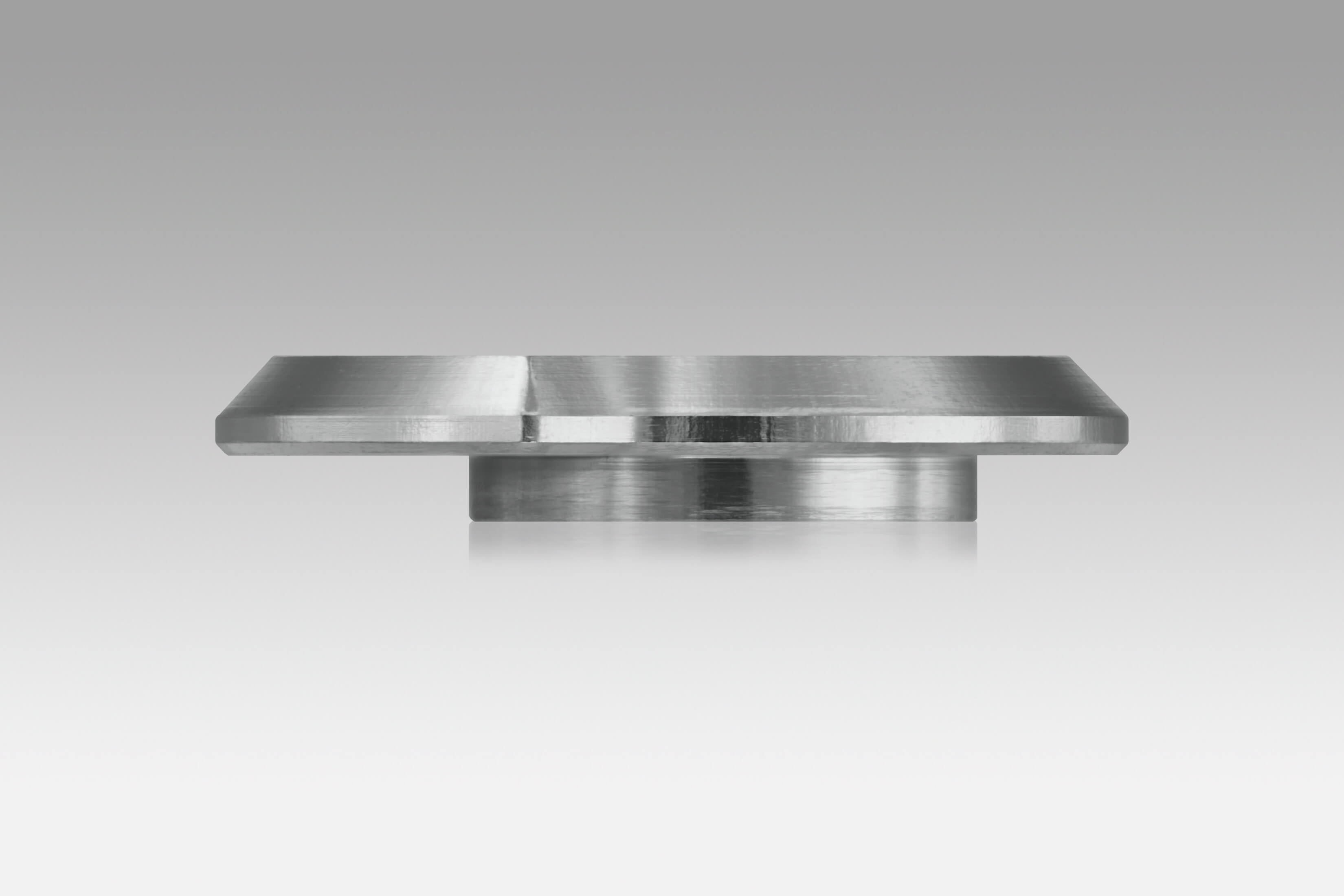

Examples of watchmaking parts

| Assembly tools, balance staffs, cams, curb pins, day star cores, distance pieces, double plates, dowel pins, eccentric cams, end pieces, ferrules, followers, index pins, journals, knurled shafts, pinions, posts, screw feet, studs, watchmaking screws, winding stems, etc.

|